Mud-sand-water filtering device for laboratories and vibration anti-blocking method

A laboratory and water filtration technology, applied in the direction of filtration separation, separation method, filtration loop, etc., can solve the problems of increasing the load of the drainage system, drainage blockage, waste of experimental materials, etc., to reduce the waste of mud and sand, reduce the burden, and effectively Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

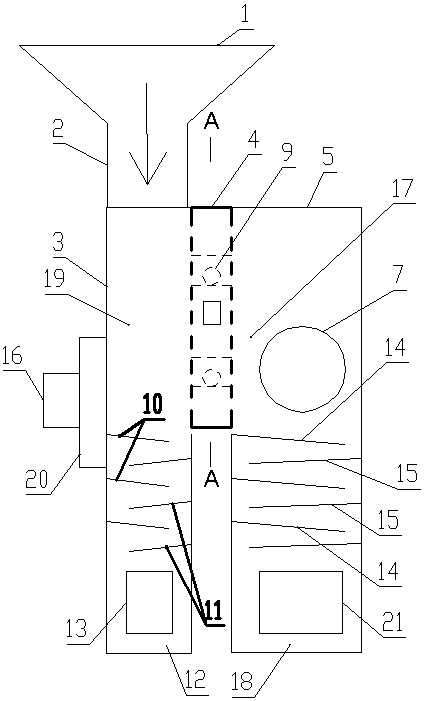

[0026] like figure 1 and figure 2 As shown, the laboratory-use mud sand water filtration device of the present invention comprises a large upper and lower small conical water inlet hopper 1, and the water inlet hopper 1 is connected with a water inlet pipe 2 downward;

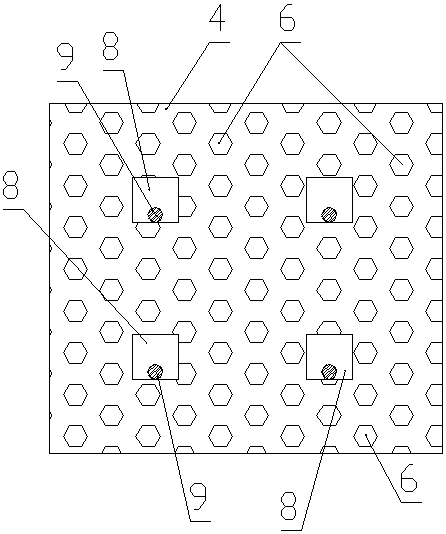

[0027] The water inlet pipe 2 is connected downward with a water inlet chamber 3, the side wall of the water inlet chamber 3 is connected with a filter plate 4, the filter plate 4 is connected with a water outlet chamber 5, and a plurality of water inlet chambers 3 and water outlet chambers are distributed on the filter plate 4. 5; the water outlet chamber 5 is connected with a water outlet pipe 7; a plurality of vibration chambers 8 are evenly arranged in the filter plate 4, and elastic balls 9 are respectively arranged in each vibration chamber 8.

[0028] When water passes through the filter plate 4, the filter holes 6 are easily blocked. Under the action of water flow disturbance and impact on the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com