Reinforcing assembly structure of waterproof base tray of integrated bathroom

A technology for assembling structures and toilets, applied in water supply devices, drainage structures, waterway systems, etc., can solve the problems of high operating costs, difficult to meet production needs, and single processing methods for enterprises, so as to reduce operating costs of enterprises and prevent a large amount of seepage. Leaky, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

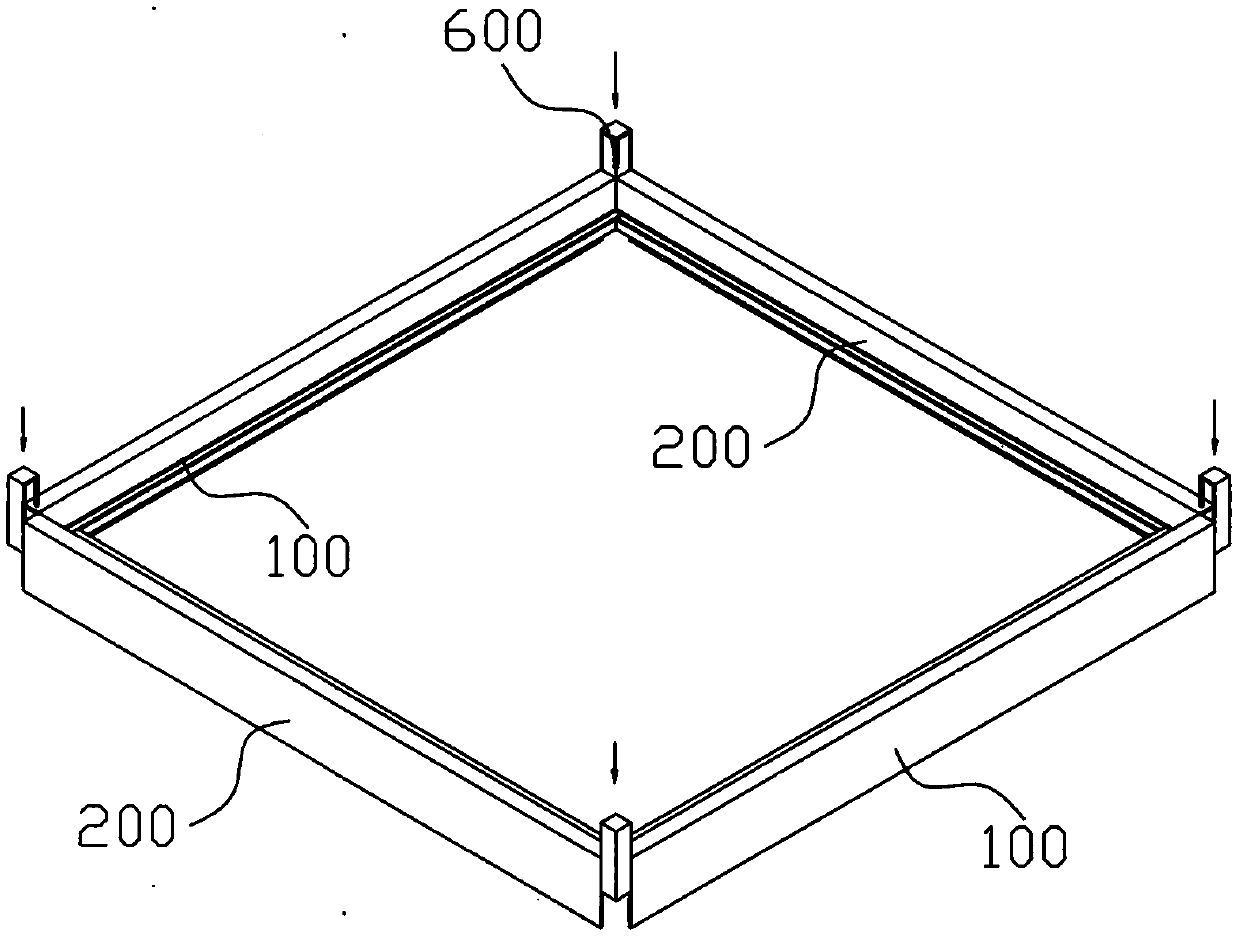

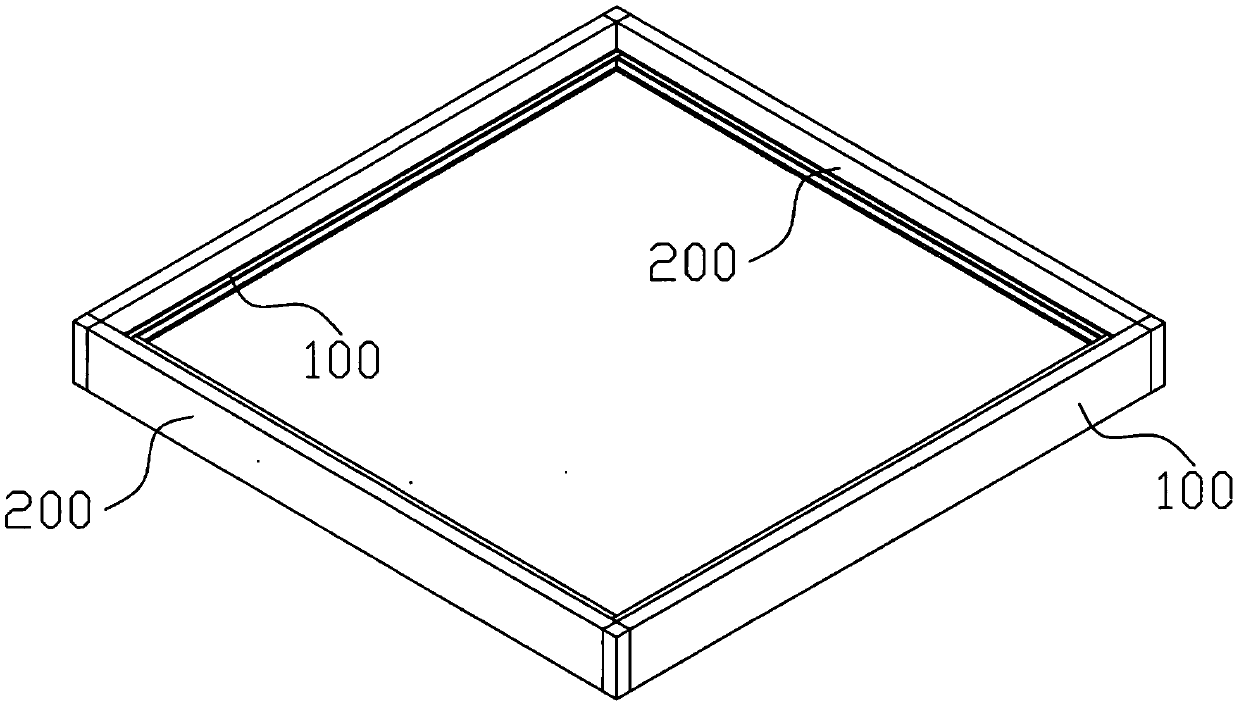

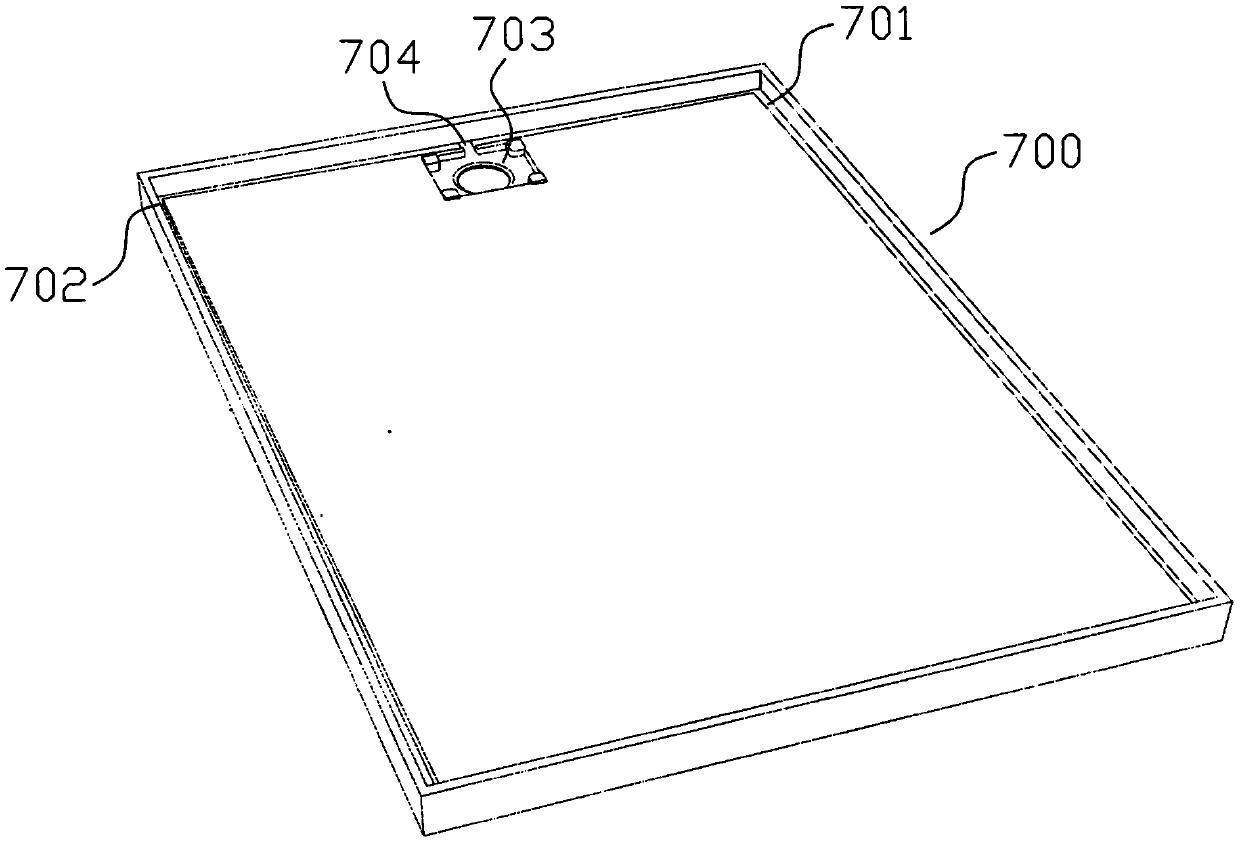

[0035] according to Figure 1 to Figure 8 Shown: This embodiment provides a reinforced assembly structure for an integral toilet waterproof chassis, including a chassis body 700, clips 600 and reinforcement profiles, and the clips 600 and reinforcement profiles are respectively used to install around the chassis body 700 for its edge. Reinforcement, the specific structure and connection relationship of each component are described as follows;

[0036] The material of the chassis body 700 is foamed ceramics. The foamed ceramics itself is light in weight, low in hardness and stable in shape. It can be processed and formed by numerical control equipment such as a milling machine. The chassis body 700 is a rectangular o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com