Self-supporting semi-dry method prefabricated column connection and construction method thereof

A construction method and prefabricated column technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of immature design methods and the superiority of difficult-to-assemble buildings, and achieve the effects of convenient engineering design, superior overall performance, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

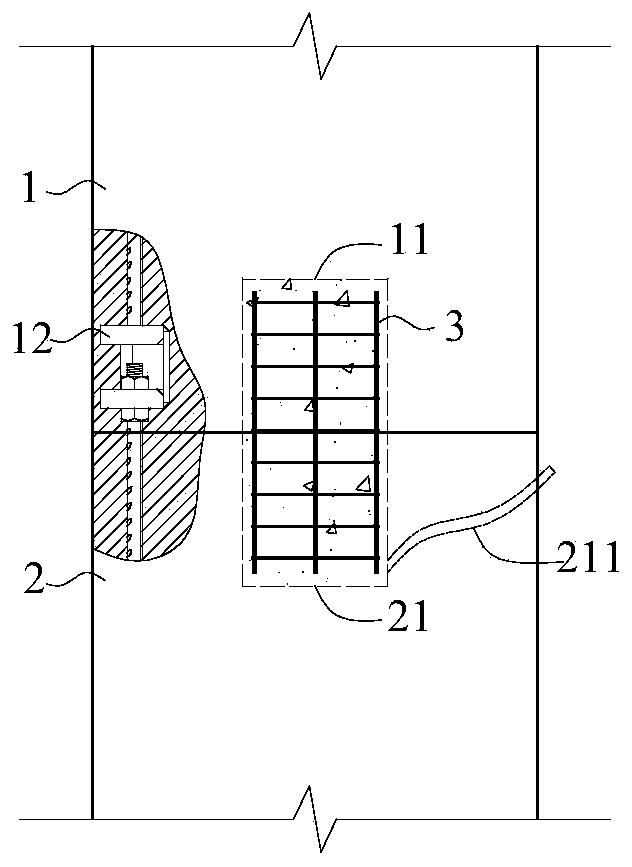

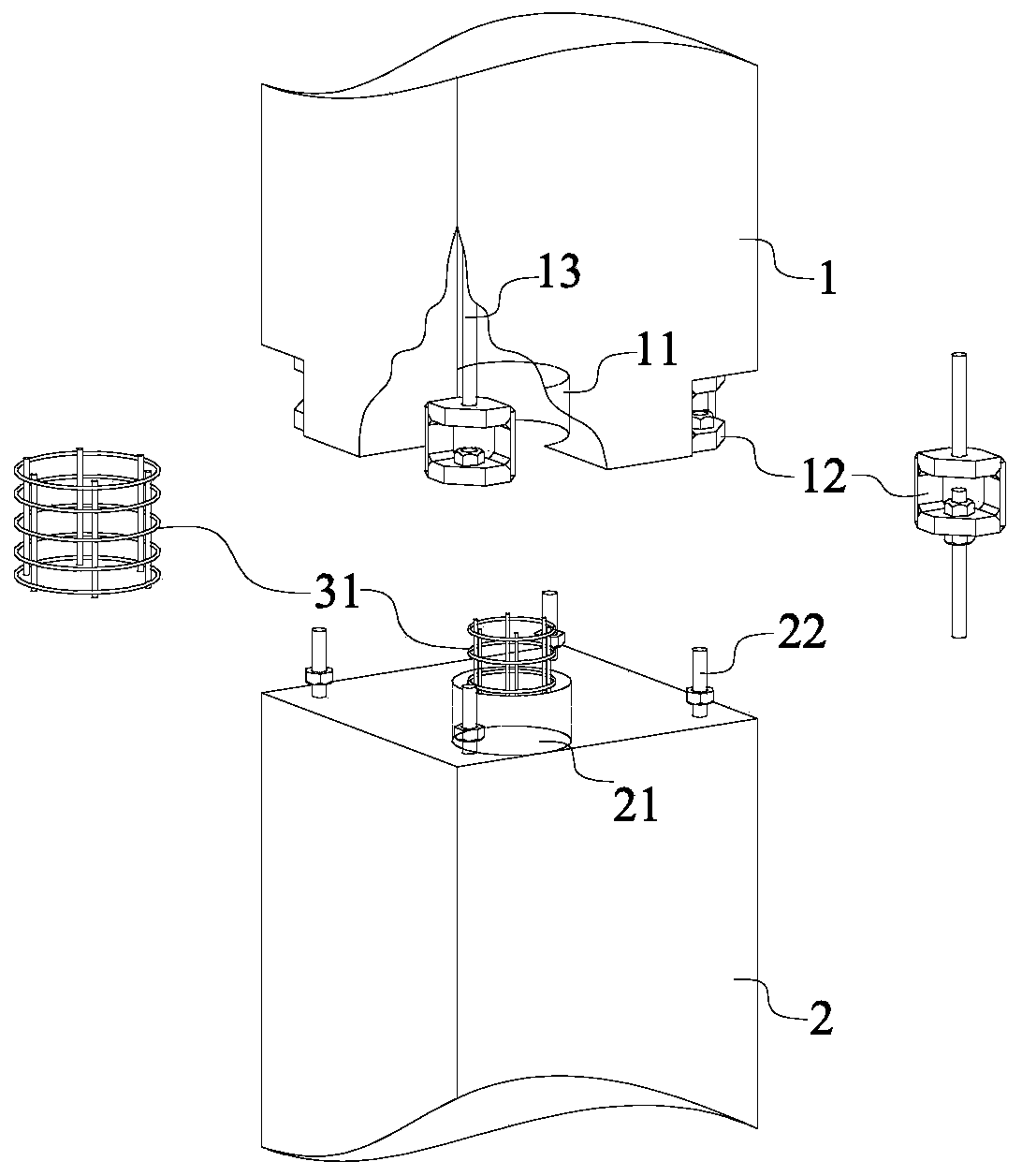

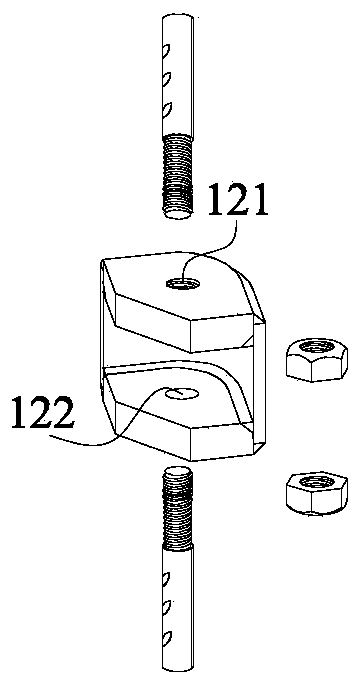

[0027] Such as Figure 1~3 A self-supporting semi-dry prefabricated column connection includes an upper prefabricated column 1, a lower prefabricated column 2 and a steel cage 31, the lower end of the upper precast column 1 is provided with a circular first reserved hole 11 and a connection box 12, and the upper precast column 1 The end of the first longitudinal rib 13 is screwed into the threaded hole 121 on the top plate of the connection box 12 . The bottom surface of the connection box 12 coincides with the lower end surface of the upper prefabricated column 1 , and a bottom plate hole 122 is opened on the bottom plate of the connection box 12 . The upper end of the lower prefabricated column 2 includes a second reserved hole 21 and a second longitudinal rib 22 protruding from the outer surface of the upper end with threads. The top threaded section of the second longitudinal rib 22 of the lower prefabricated column 2 is matched with the bottom plate hole 122 of the conne...

Embodiment 2

[0034] Such as Figure 4~5 , this embodiment is the same as the rest of embodiment 1, except that the side of the upper prefabricated column 1 is provided with a first reserved channel 111 .

[0035] The specific construction method includes the following steps:

[0036] (a) Screw the end of the first longitudinal rib 13 of the upper prefabricated column 1 into the internally threaded hole 121 on the top plate of the connection box 12, so that the first longitudinal rib 13 is fixedly connected with the connection box 12;

[0037] (b) Put the reinforcement cage 31 into the second reserved hole 21 of the lower prefabricated column 2, and pour concrete into the second reserved hole 21 of the lower precast column 2 along the second reserved channel 211;

[0038] (c) pass the second longitudinal rib 22 of the lower prefabricated column 2 through the bottom plate hole 122 of the connection box 12, and fix it with bolts;

[0039] (d) Filling the first reserved hole 11 of the upward...

Embodiment 3

[0041] Such as Figure 6~7 , This embodiment is the same as the rest of Embodiment 1, except that the reinforcement cage 31 is replaced by H-shaped steel 32 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com