Hydraulic oil tank and vehicle

A hydraulic oil tank and box body technology, which is applied in the direction of oil supply tank devices and mechanical equipment, can solve the problems that the hydraulic oil tank cannot meet the layout requirements and use requirements of the electric drive chassis, so as to save refueling space, facilitate the layout of the whole vehicle, and ensure The effect of pressure balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

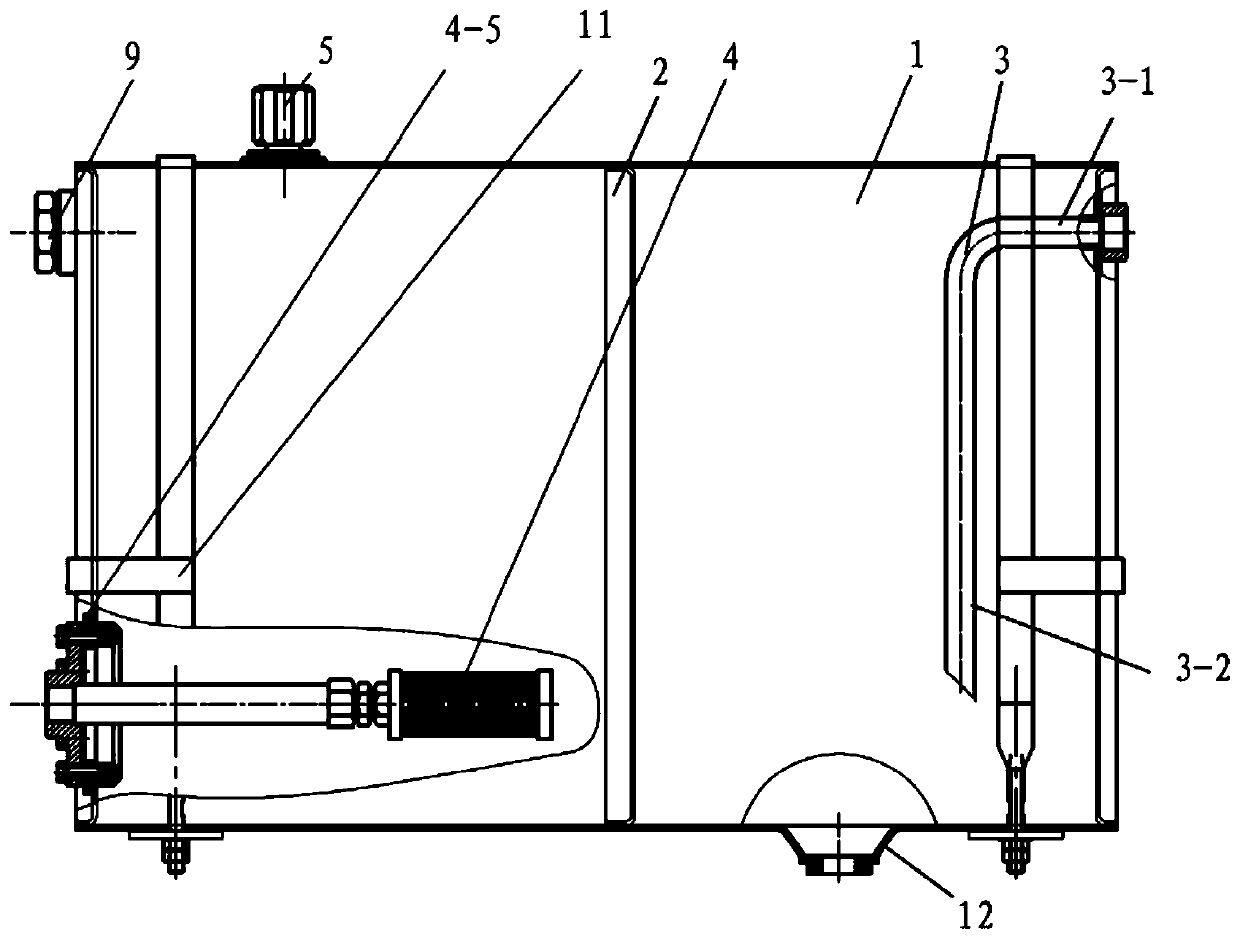

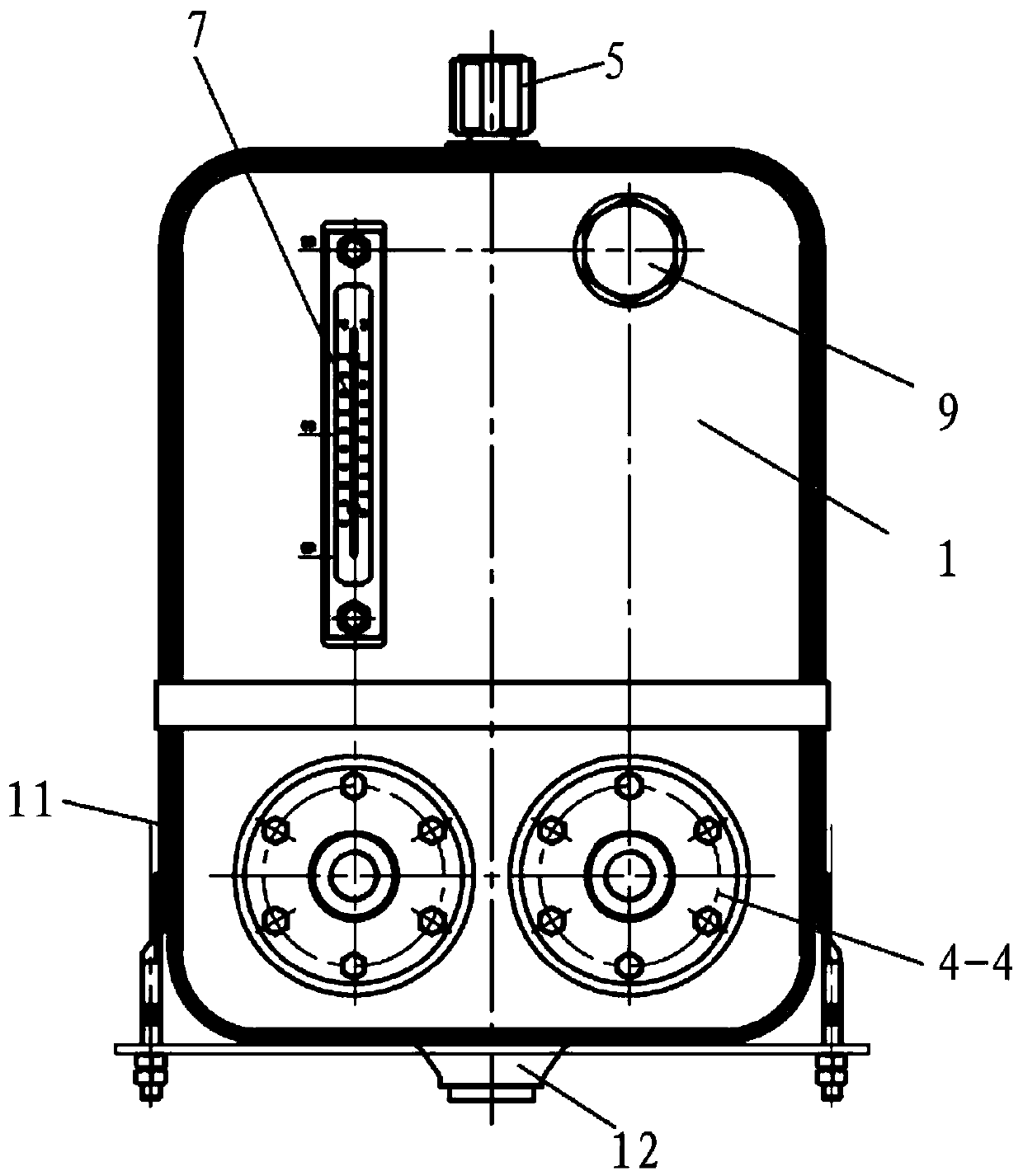

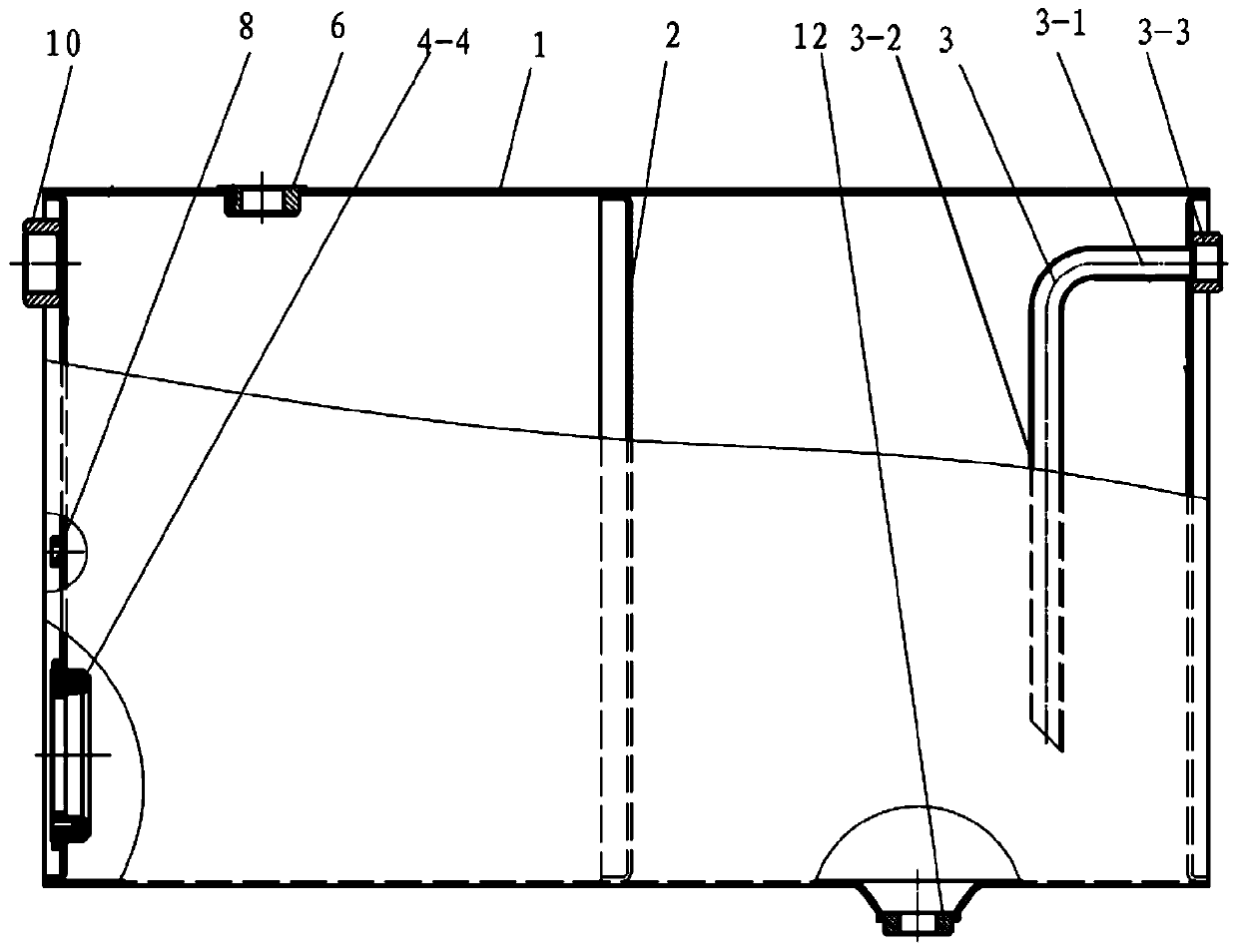

[0023] see Figure 1-4 , A hydraulic oil tank provided by an embodiment of the present invention includes: a tank body 1 and a partition 2 .

[0024] The partition plate 2 is fixedly arranged in the box body 1 and divides the box body 1 into a first cavity and a second cavity. The partition plate 2 is provided with a plurality of through holes.

[0025] The upper part of the first side of the box body 1 is provided with an oil filling port, and the lower part of the first side of the box body 1 is provided with an oil suction port, and both the oil filling port and the oil suction port communicate with the first cavity.

[0026] An oil return port is opened on the upper part of the second side of the case body 1, and the oil return port communicates with the second cavity, and the first side of the case body 1 is opposite to the second side of the case body.

[0027] The top of the box body 1 is provided with an air vent.

[0028] Specific embodiments of the present applicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com