Gearbox oil return structure

A gearbox and oil return technology, which is applied in gear lubrication/cooling, belt/chain/gear, fixed filter elements, etc., can solve problems such as oil return blockage, avoid blockage, improve filtering effect, and ensure oil return cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

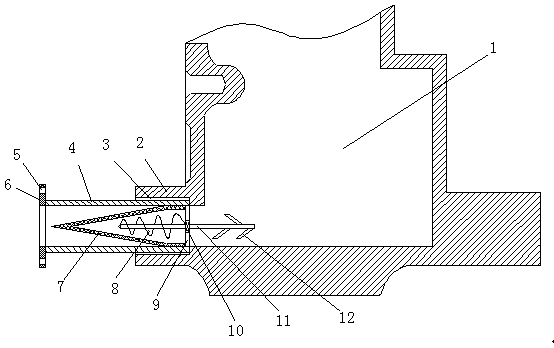

[0028] Embodiment 1, referring to the figure, an oil return structure of a gear box, including a box body 1, an oil return pipeline 4 is arranged at the bottom of the box body 1, and the oil return pipeline 4 is detachably sealed with the box body 1, and the oil return pipeline The pipeline 4 is provided with an oil-driven micro-power return oil disturbance filter mechanism.

[0029] When working, the micro-power oil return disturbance filter mechanism is driven by the oil return oil to perform disturbance filtration, which greatly improves the oil return filtration effect, effectively prevents the blockage of the oil return oil circuit, and facilitates the normal oil return circulation of the oil in the tank 1. Ensure the normal lubrication of the parts in the box body 1 and return the oil to cool down.

[0030] Wherein, the micro-power oil return disturbance filter mechanism includes a filter screen cylinder 7, the open end of the filter screen cylinder 7 is installed in the...

Embodiment 2

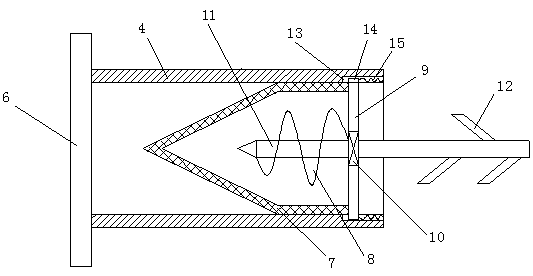

[0037] Embodiment two, refer to figure 2 ; The present embodiment increases the following technical features on the basis of Embodiment 1:

[0038] Among them, the grid frame 9 is elastically slidingly matched with the oil return pipeline 4; the filter screen cylinder 7 and the grid frame 9 can reciprocate at the end of the oil return pipeline 4, and the filter screen cylinder 7 and the grid frame 9 are pushed by the oil Reciprocating motion further improves the effect of too fast disturbance.

[0039] Wherein, the oil return pipeline 4 is provided with a chute 13 in the port close to the side of the box body 1, and the chute 13 is arranged symmetrically up and down along the port of the oil return pipeline 4, and the top and bottom of the grid frame 9 are respectively provided with sliders 14, The slider 14 is set in the chute 13, and the chute 13 is provided with a telescopic spring 15. One end of the telescopic spring 15 is fixedly connected with the slider 14, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com