Automatic sewage discharging device and control method thereof

An automatic sewage and sewage valve technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of reduced use efficiency, single sewage method, and structural limitations of sewage devices, and achieve efficient installation and improve sewage. Efficiency, the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

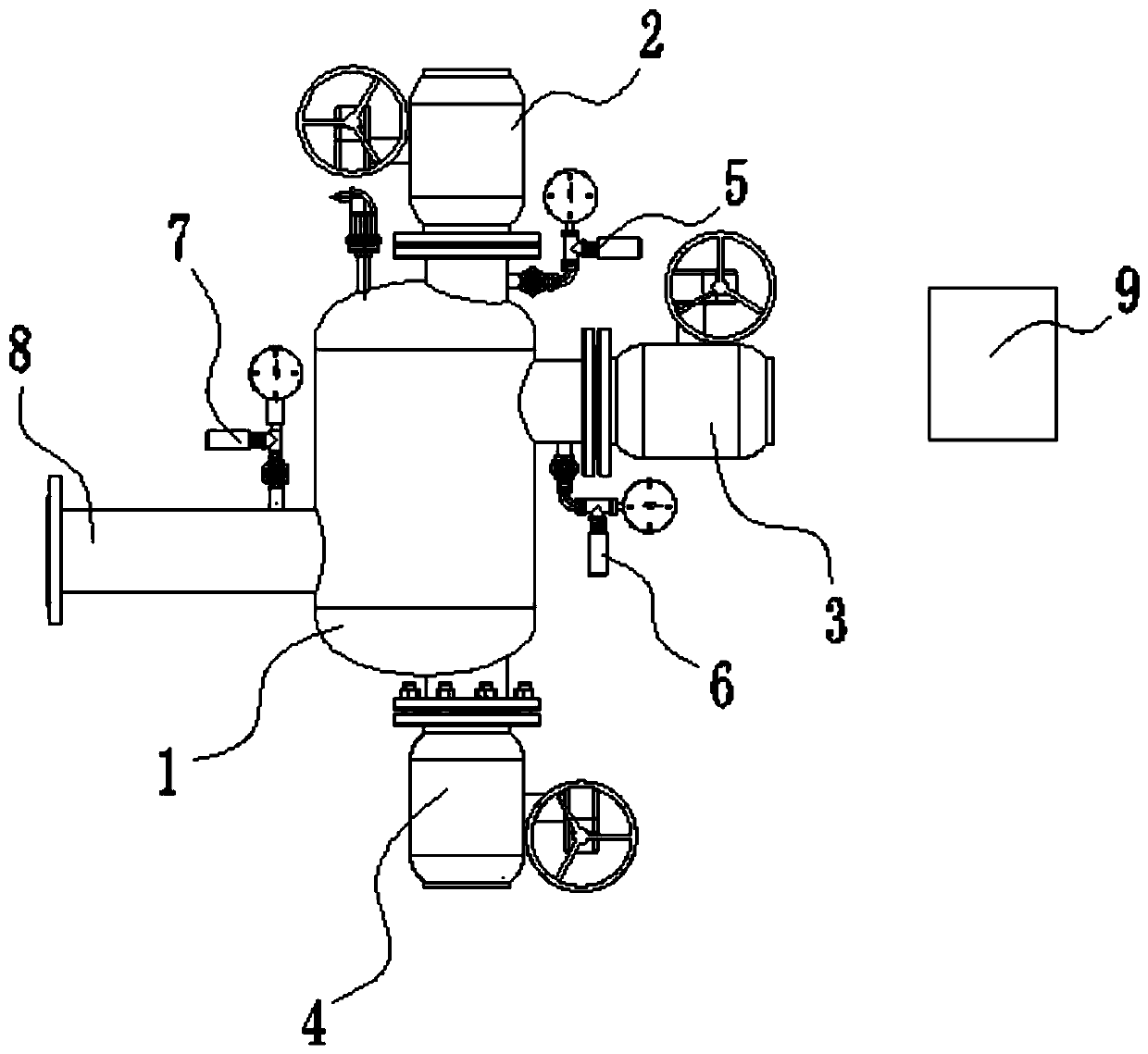

[0026] Any one of the electric control valve 2 or the electric control valve 3 is connected to the pipeline system, and the other electric control valve not connected to the pipeline system is closed. The pressure sensor 5 or the pressure sensor 6 detects the current water inlet pressure value, and at the same time detects the water pressure of the water pipe. 8, the water inlet pressure value and the water outlet pressure value are uploaded to the controller 9, and the controller 9 calculates the pressure difference. The controller 9 has a preset pressure difference value. When the pressure difference is greater than The preset pressure difference indicates that the pressure in the tank 1 is unbalanced due to more dirt at the port. At this time, the automatic sewage discharge program is entered. The automatic sewage discharge program is as follows:

[0027] First, close all the electric regulating valves through the controller 9, and then the controller 9 controls the opening ...

Embodiment 2

[0029] Both the electric regulating valve 2 and the electric regulating valve 3 are connected to the pipeline system, and the current water inlet pressure value is detected by the pressure sensor 5 and the pressure sensor 6, and the water outlet pressure value at the water pipe 8 is detected at the same time, and the water inlet pressure value and the water outlet pressure value are compared. The pressure value is uploaded to the controller 9, and the controller 9 calculates the pressure difference. The preset pressure difference is set in the controller 9. When the pressure difference of any group is greater than the preset pressure difference, it means that the tank In body 1, the pressure at the port is unbalanced due to more dirt. At this time, it enters the automatic sewage discharge procedure. The automatic sewage discharge procedure is as follows:

[0030] Firstly, the electric control valve 2 and the electric control valve 3 are closed by the controller 9, and then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com