LED strip ceiling structure and mounting method thereof

A ceiling structure and LED light panel technology, applied in lighting devices, fixed lighting devices, lighting auxiliary devices, etc., can solve the problems of uncoordinated ceiling decoration, difficult installation, awkward shape, etc., saving external space and simple installation method. , the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

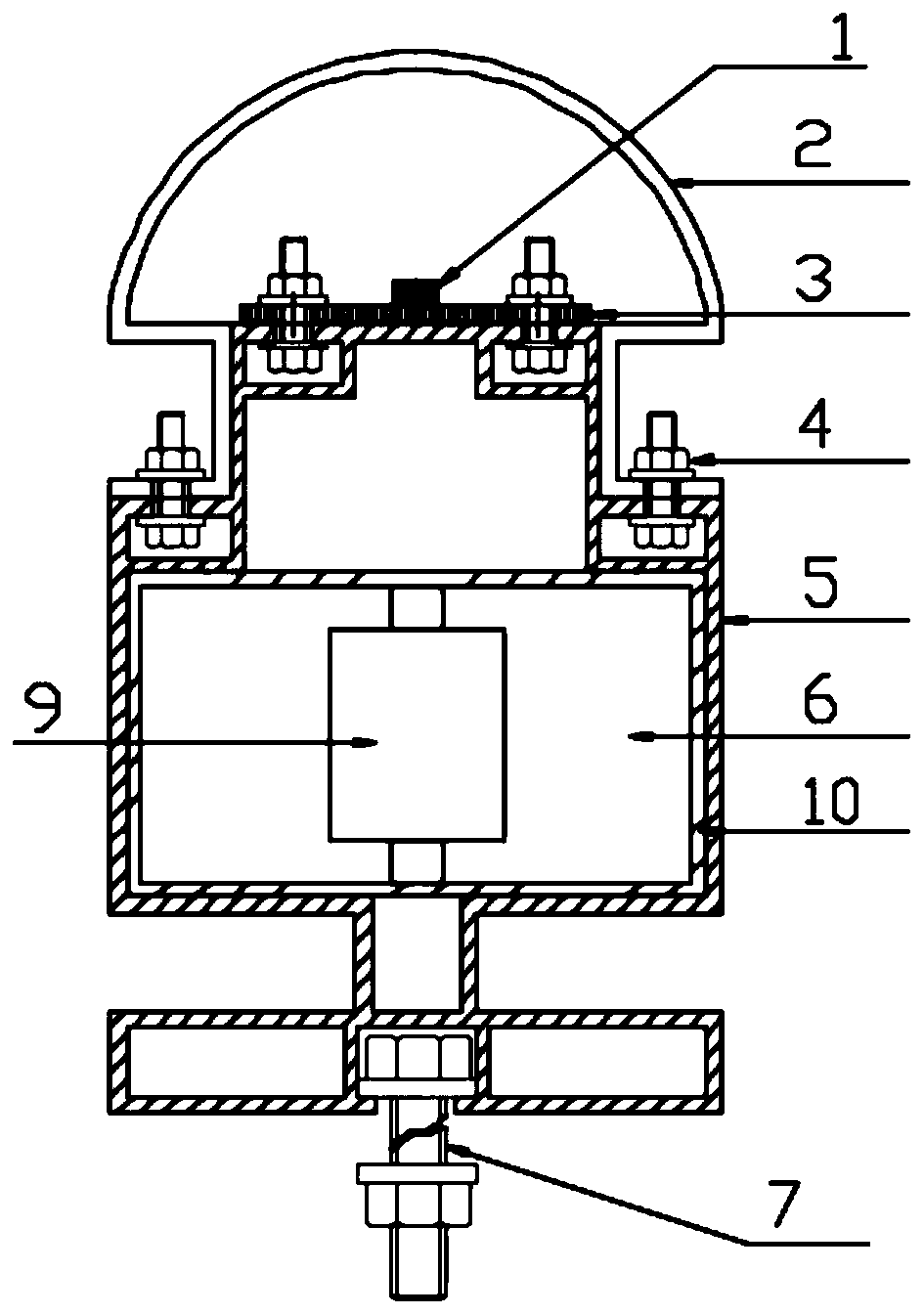

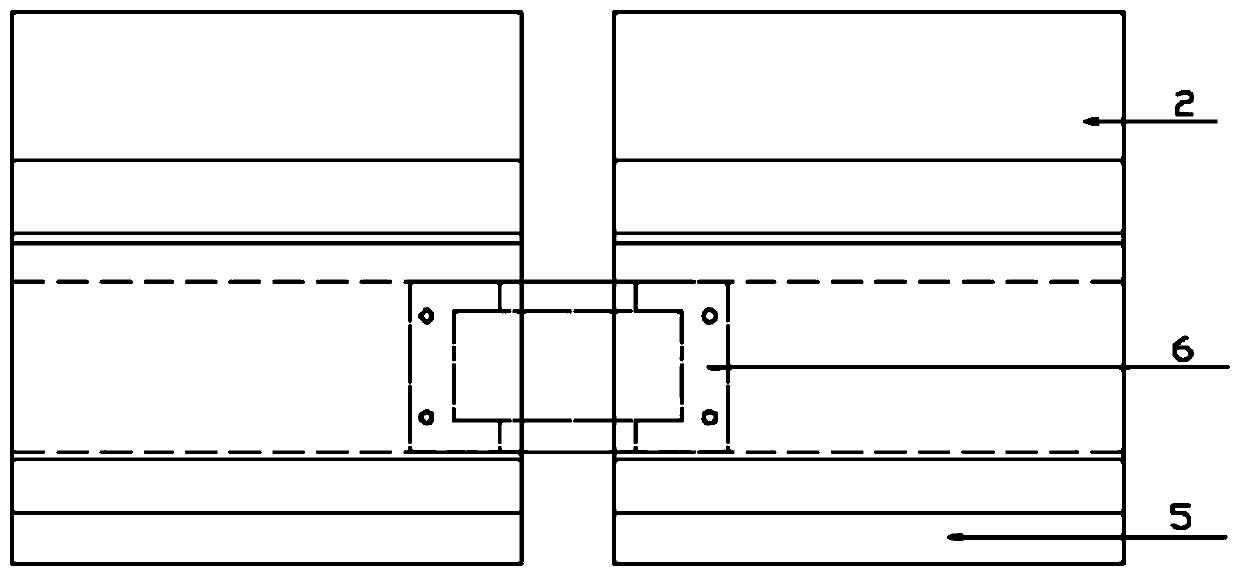

[0030] see Figure 1~3 , in an embodiment of the present invention, an LED strip ceiling structure includes an LED wick 1, a strip grid 5 and a power connector 6, the strip grid 5 is made of aluminum alloy or light steel material, and the strip Shaped grille 5 can formulate actual needs according to the overall modeling style of the ceiling and the fixed installation method, and is convenient to the molding of hoisting.

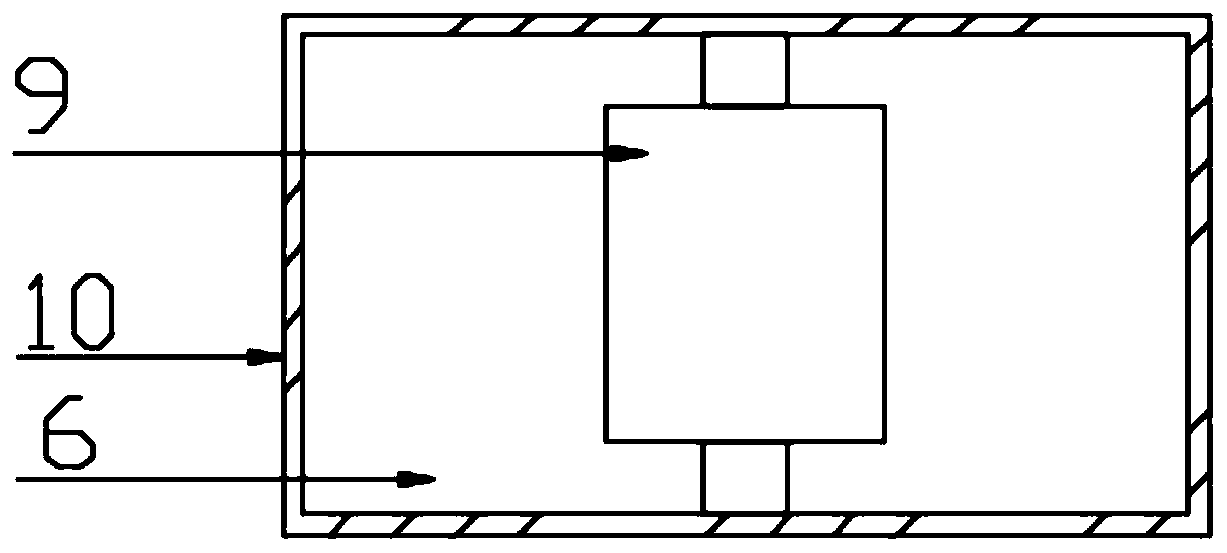

[0031] The power supply connector 6 is fixedly installed with one end of the strip grille 5, and the power connector 6 is composed of a connection housing 10 and an LED power supply and control device 9. The LED power supply and control device 9 are fixedly installed and connected in the housing 10, and the LED power supply and The control device 9 is electrically connected with a power line 8, and the end of the power line 8 away from the LED power supply and the control device 9 extends to the outside of the connecting shell 10, and the connecting shell 10 ...

Embodiment 2

[0039] An LED strip ceiling structure, which combines lamps and ceiling strip grids to form a decorative ceiling material with both decorative and lighting functions. It is creative, unique in style, elegant in appearance, and low in cost; And the heat-conducting insulating coating greatly improves the heat-conducting performance of the structure, guarantees and prolongs the service life of the LED light-emitting wick 1.

[0040] The working principle of the present invention is: when the present invention is in use, first use the suspender 7 of the corresponding specification to fix the strip grid 5 on the roof according to the requirements of the construction project, and then splice the strip grid 5 through the power connector 6 Fix it, then connect the power cord 8 to the circuit bus, then install the LED lamp board 3, the lampshade 2 and the lampshade cover in sequence to complete the installation. The structure is simple, convenient and practical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com