Heating slurry material printed on ceramic atomization core, ceramic atomization core and production method thereof

A technology of atomizing cores and paddles, applied in the field of electronic cigarettes, can solve problems such as easy disconnection of smoke, poor taste, and bad taste, and achieve the effects of low cost, good taste, and few components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In terms of percentage by weight, the heat-generating slurry is prepared by mixing the following components: 89% of 306 stainless steel nanopowder, 4.5% of 209 glass powder, and 6.5% of epoxy resin.

Embodiment 2

[0030] In terms of weight percentage, the heating paste comprises the following components mixed: 90% of 306 stainless steel nanometer powder, 4% of 209 glass powder, and 6% of epoxy resin.

Embodiment 3

[0032] In terms of percentage by weight, the heat-generating slurry is prepared by mixing the following components: 91% of 306 stainless steel nanopowder, 3.5% of 209 glass powder, and 5.5% of epoxy resin.

[0033] The resistance values of the three embodiments of the heat-generating paste printed on the microporous ceramic plate are all between 0.9 and 1.3 ohms, wherein the resistance value of the first embodiment is relatively large, and the resistance value of the third embodiment is relatively small.

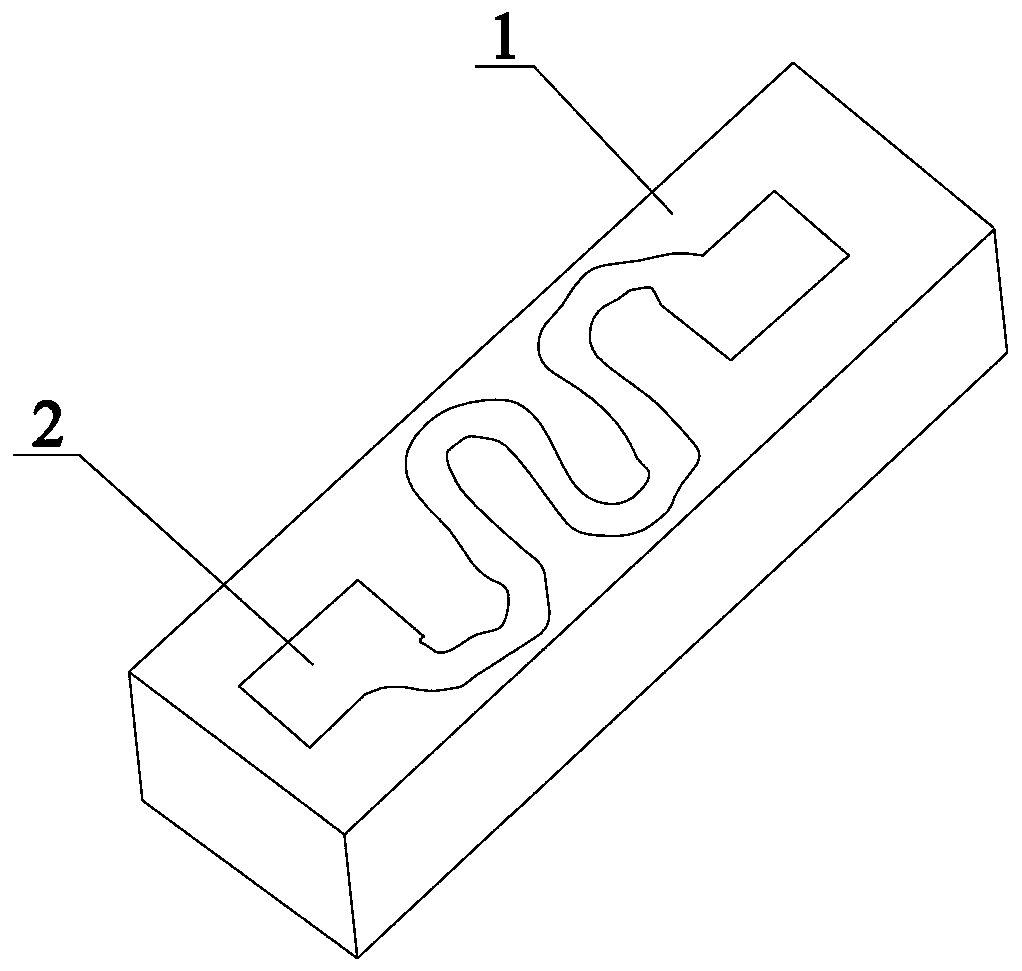

[0034] Such as figure 1 As shown, the second technical solution of the present invention: a ceramic atomizing core, including a cuboid microporous ceramic substrate 1, an "S" shaped heating circuit 2 sintered with the microporous ceramic substrate 1, the heating circuit 2 is printed on the microporous The heat-generating paste on one surface of the porous ceramic substrate 1 is sintered.

[0035] The third technical solution of the present invention: a production method o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com