Heat exchange tube spacing keeping structure

A heat exchange tube and spacing technology, applied in the field of heat exchange tube spacing maintenance structure, can solve the problems of maintaining the heat exchange tube spacing, unable to load and unload catalysts, etc., and achieve the effect of reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

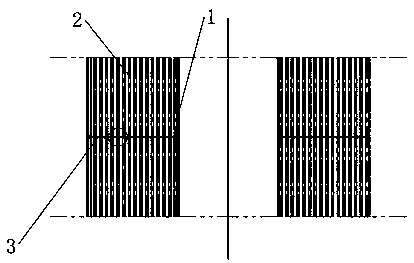

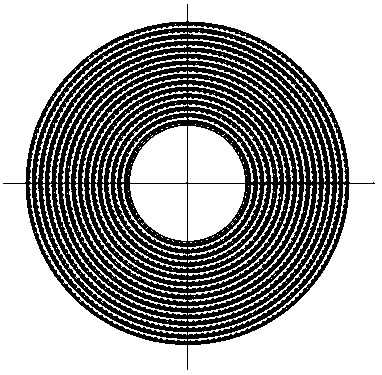

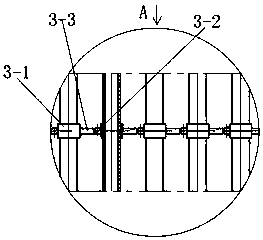

[0014] Such as Figure 1-4 As shown, a reactor tube bundle is used for a reactor tube bundle, and the reactor tube bundle includes an inner cylinder 1 and a plurality of heat exchange tubes 2, and a heat exchange tube distance maintenance structure 3 is used between the inner cylinder 1 and the plurality of heat exchange tubes 2 Fixed-distance connection; the heat exchange tube spacing maintenance structure 3 includes a number of ring sets 3-1, and all the ring sets 3-1 form several layers of concentric circles distributed concentrically; between two adjacent layers of ring sets 3-1, there are Positioning ring 3-2 and some positioning blocks 3-3, positioning ring 3-2 is set on all finger ring sleeves 3-1 of the inner layer, and is connected with all ring sleeves 3-2 of the inner layer by spot welding, positioning block 3- 3 Evenly distributed on the outer circumference of the positioning ring 3-2, spot welding connection with the positioning ring 3-2, and one-to-one correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com