Path planning device and path planning method for laser shot peening strengthening curved surface

A technology of laser shot peening and path planning, which is applied in the field of path planning of laser shot peening surface and path planning device of laser shot peening surface, can solve the problems of detection and elimination, large focusing error, large trajectory error, etc. Improve the utilization rate and ensure the effect of uniform consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described in detail below.

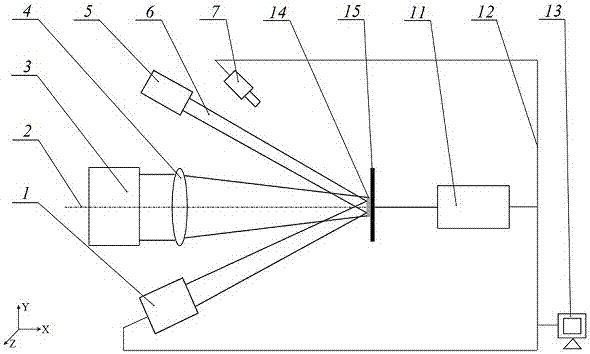

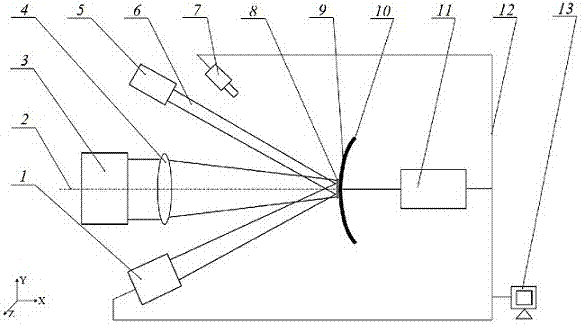

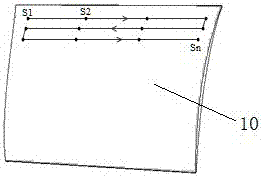

[0025] Such as figure 1 , figure 2As shown, the present invention is a path planning device for laser shot peening to strengthen curved surfaces, which includes a high-energy pulse laser 3, a positioning laser 5 symmetrically arranged on both sides with the centerline of the high-energy laser beam emitted by the high-energy pulse laser 3 as the working axis 2, and CCD display 1, a convex lens 4 positioned at the high-energy laser beam position on the front side of the high-energy pulse laser 3, a calibration block 15 with a calibration plane perpendicular to the working axis, a calibration reflective film 14 attached to the calibration plane, and a clamp to clamp the calibration block Or the workpiece and the manipulator 11 that can freely adjust its position and direction, the industrial computer 13 that is electrically connected to the CCD display 1 and the manipulator 11 through the data line, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com