Internet of Things intelligent gas meter electromechanical valve gearbox gear set assembling system and method

A technology of assembly system and gearbox, applied in the direction of assembly machine, conveyor objects, transportation and packaging, etc., can solve the problems of easy introduction of dust, low efficiency, small diameter and size of gears, etc., to ensure the accuracy and stability of horizontal positioning , High installation efficiency, accurate grasping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. As a limitation of the present invention.

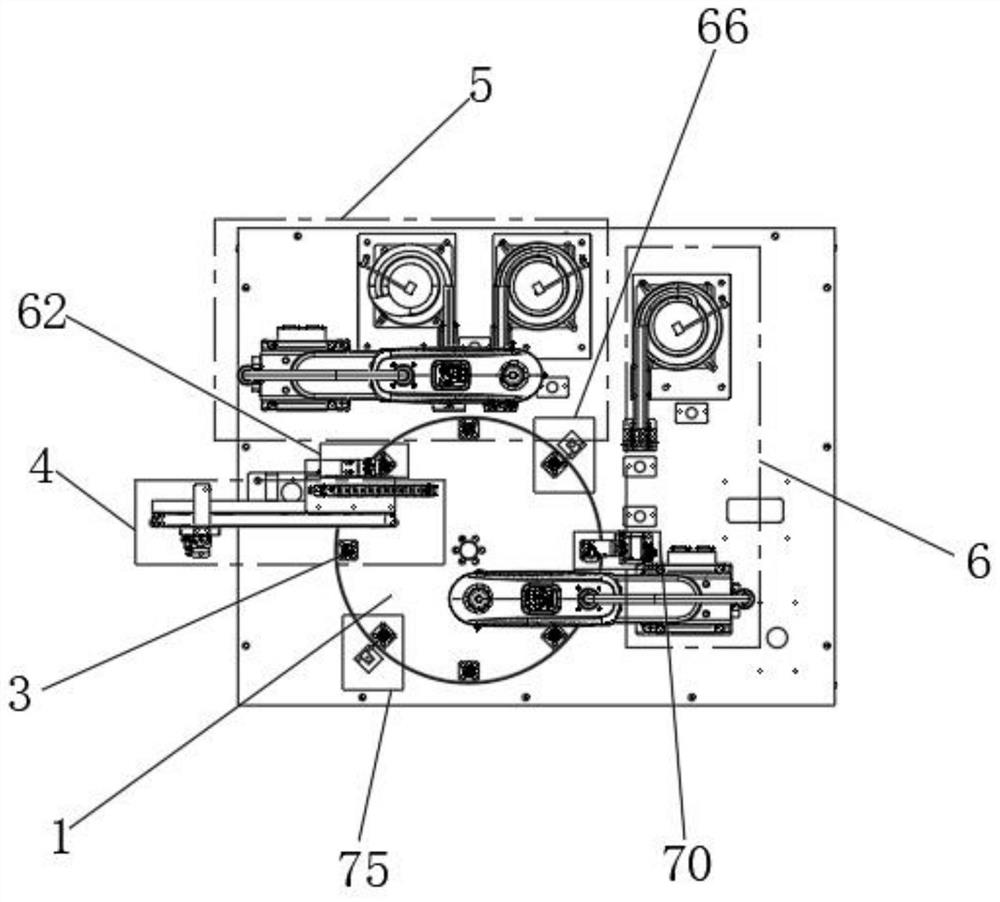

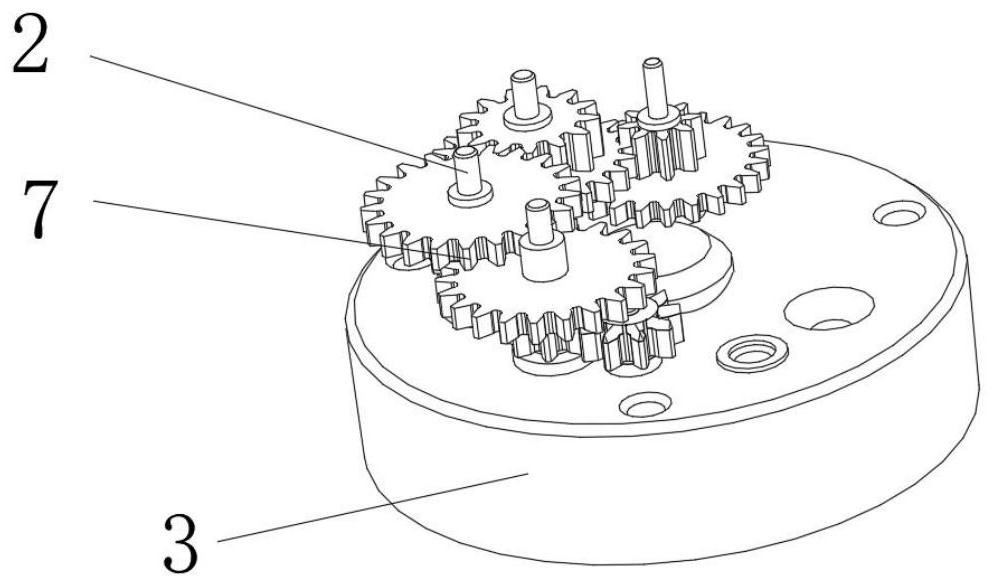

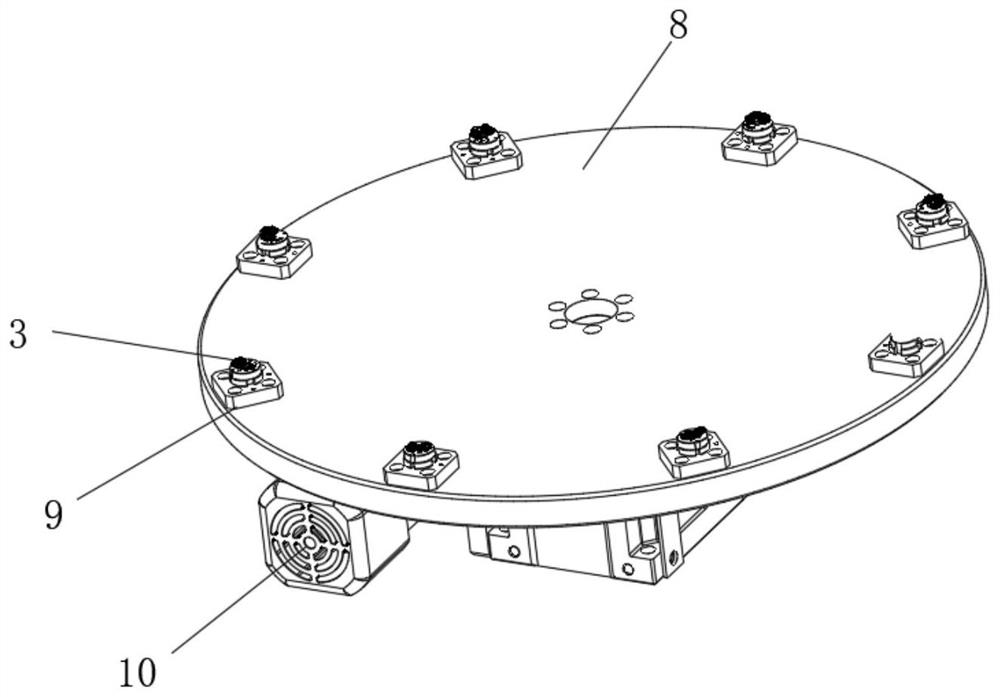

[0074] like figure 1 , figure 2 As shown, the Internet of Things intelligent gas meter electromechanical valve gearbox gear set assembly system of this embodiment includes a gearbox cover delivery system 1 for delivering the gearbox cover 3 with the gear shaft 2 installed;

[0075] It also includes those arranged in sequence along the conveying direction of the gearbox cover:

[0076] The gearbox cover feeding system 4 is used to grab the gearbox cover 3 to the gearbox cover conveying system 1;

[0077] The lower gear assembly system 5 is used to sequentially assemble the lower gears on the gear shaft 2;

[0078] The upper gear assembly system 6 is used to sequentially assemble the upper gears on the ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com