Sewage pipeline capable of realizing graded discharge

A technology of sewage pipelines and secondary pipelines, applied in the direction of sewage discharge, sewer pipeline systems, waterway systems, etc., can solve the problems of increasing manpower and material resources, unfavorable sewage recycling and utilization, and the inability to choose discharge locations and disinfection methods, etc., to reduce labor The effect of increasing the amount and accelerating the emission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

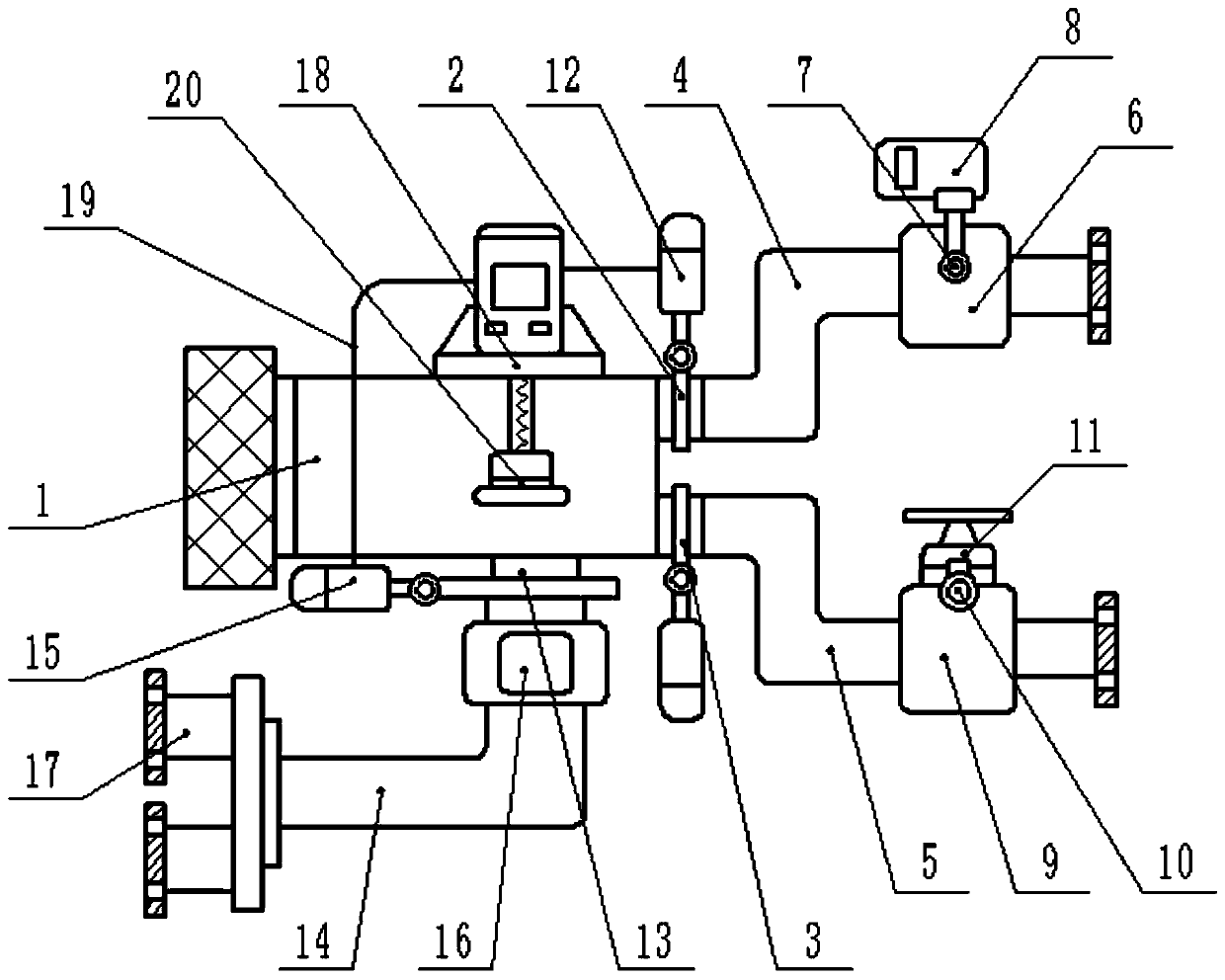

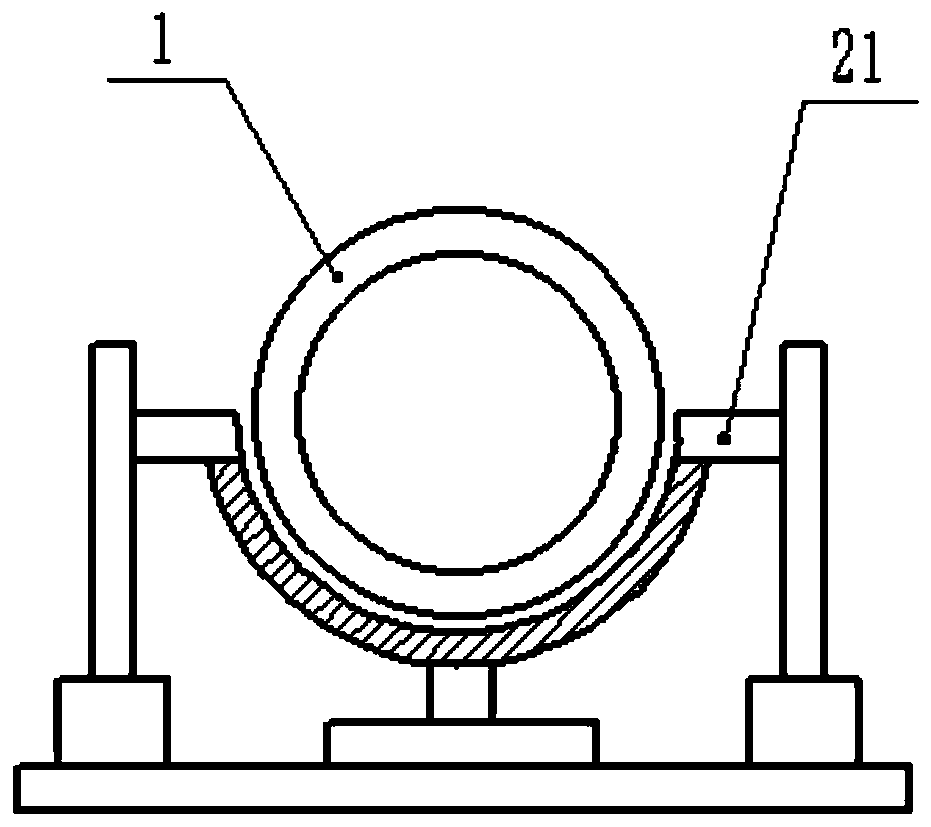

[0015] Such as Figure 1-2 As shown, a sewage pipe for graded discharge includes a main pipeline 1, a secondary pipeline 4, a tertiary pipeline 5, a chemical disinfection chamber 6, an ultraviolet disinfection chamber 9, a quaternary pipeline 14 and a PLC controller 18, and the main pipeline 1- The side is respectively connected with the secondary pipeline 4 and the tertiary pipeline 5 through the left baffle plate 2 and the right baffle plate 3, and the chemical disinfection chamber 6 and the ultraviolet disinfection chamber 9 are respectively installed on the secondary pipeline 4 and the tertiary pipeline 5, and the chemical disinfection chamber 6. The outside is connected to the disinfectant box 8 through the disinfection tube 7. The disinfectant box 8 is equipped with disinfectant, which can enter the chemical disinfection chamber 6 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com