Impact-resistant vacuum glass

A technology of vacuum glass and impact resistance, which is applied in the direction of climate change adaptation, window/door improvement, etc. It can solve problems such as seal damage, vacuum glass damage, glass plate fragmentation, etc., and achieve the effect of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

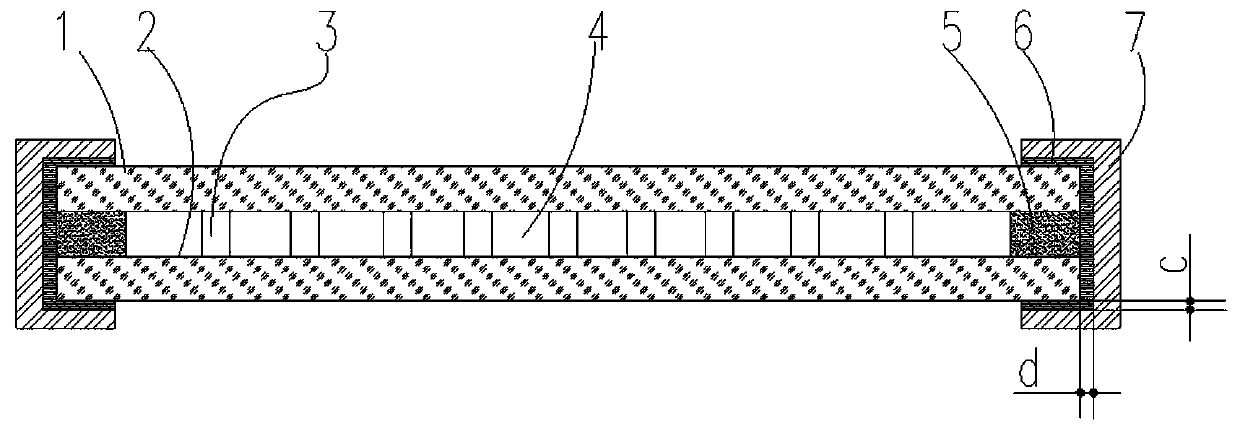

[0049] An impact-resistant vacuum glass, including a vacuum glass body. In this embodiment, the vacuum glass body includes a first glass substrate 1 and a second glass substrate 2, and the first glass substrate 1 and the second glass substrate 2 are arranged oppositely, and a metal sealing material 5 is consolidated on the inner side of the peripheral plate surface of the first glass substrate 1 and the second glass substrate 2, and a vacuum chamber 4 is formed between the two glass substrates and the metal sealing material, surrounded by Multiple supports 3 are arranged between the two glass substrates of the vacuum chamber 4 .

[0050] In this embodiment, a buffer material 6 is provided on the end face side of the periphery of the vacuum glass body and on the outer sides of the two boards of the periphery of the vacuum glass body, and a dynamic stress offset frame 7 is wrapped and fixed on the outer side of the buffer material. figure 1 It can be seen that, in this embodime...

Embodiment 2

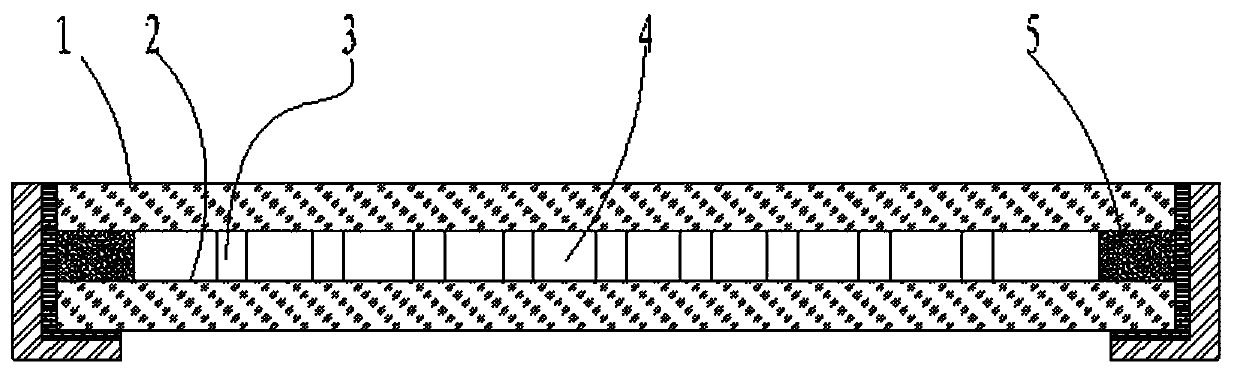

[0068] Compared with the first embodiment, the difference between this embodiment and the first embodiment is that a buffer material 6 is arranged on the end face side of the periphery of the vacuum glass body and a plate surface outside the periphery of the vacuum glass body, and a dynamic stress offset frame 7 is wrapped and fixed on the outside of the buffer material. figure 2 It can be seen that, in this embodiment, the cross-sectional shape of the dynamic stress offset frame 7 is L-shaped. The rest are all the same as in Example 1.

Embodiment 3

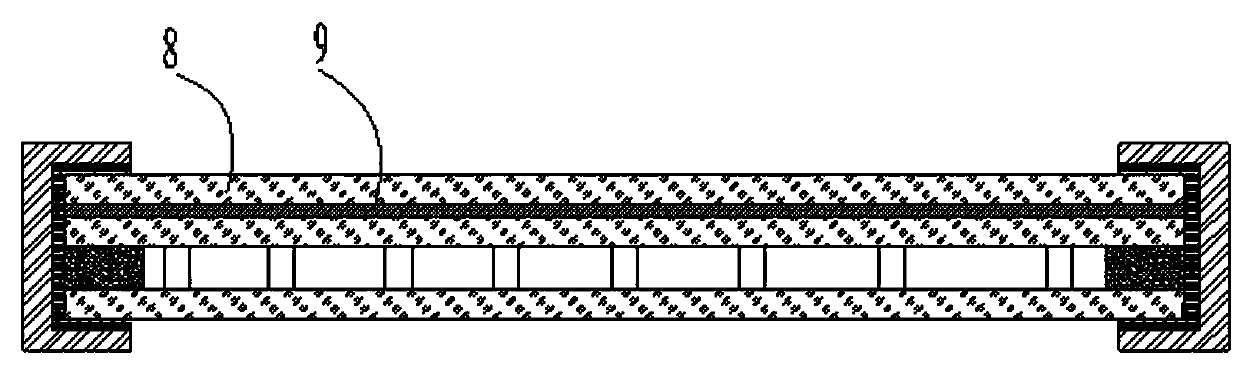

[0070] Compared with the first embodiment, the difference between this embodiment and the first embodiment is that the vacuum glass body includes a first glass substrate 1 and a second glass substrate 2 that surround the vacuum cavity, and a glass substrate that is connected to the first glass substrate 1 or the second The third glass substrate 8 where the two glass substrates 2 are oppositely arranged, the buffer material 6 is arranged on the outer side of the third glass substrate 8 in the vacuum glass body and in the first and second glass substrates away from the third glass substrate 8 The outer side of the glass substrate, such as image 3 shown.

[0071] In this embodiment, an organic polymer interlayer film 9 is arranged between the third glass substrate 8 and the first glass substrate 1 or the second glass substrate 2, and the organic polymer interlayer film 9 can be PVB, SGP, EVA, laminated glass glue, etc., the organic polymer interlayer film can be set in one or m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap