Moistening device of fabric pre-shrinking equipment

A wet supply device and wet supply technology are applied in the direction of processing textile material equipment configuration, textile material processing, and textile material drum processing. It can solve the problems of affecting the quality of pre-shrinking processing, single steam outlet, and uneven wet supply. Achieve the effect of improving steam utilization rate, prolonging service life, and small contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

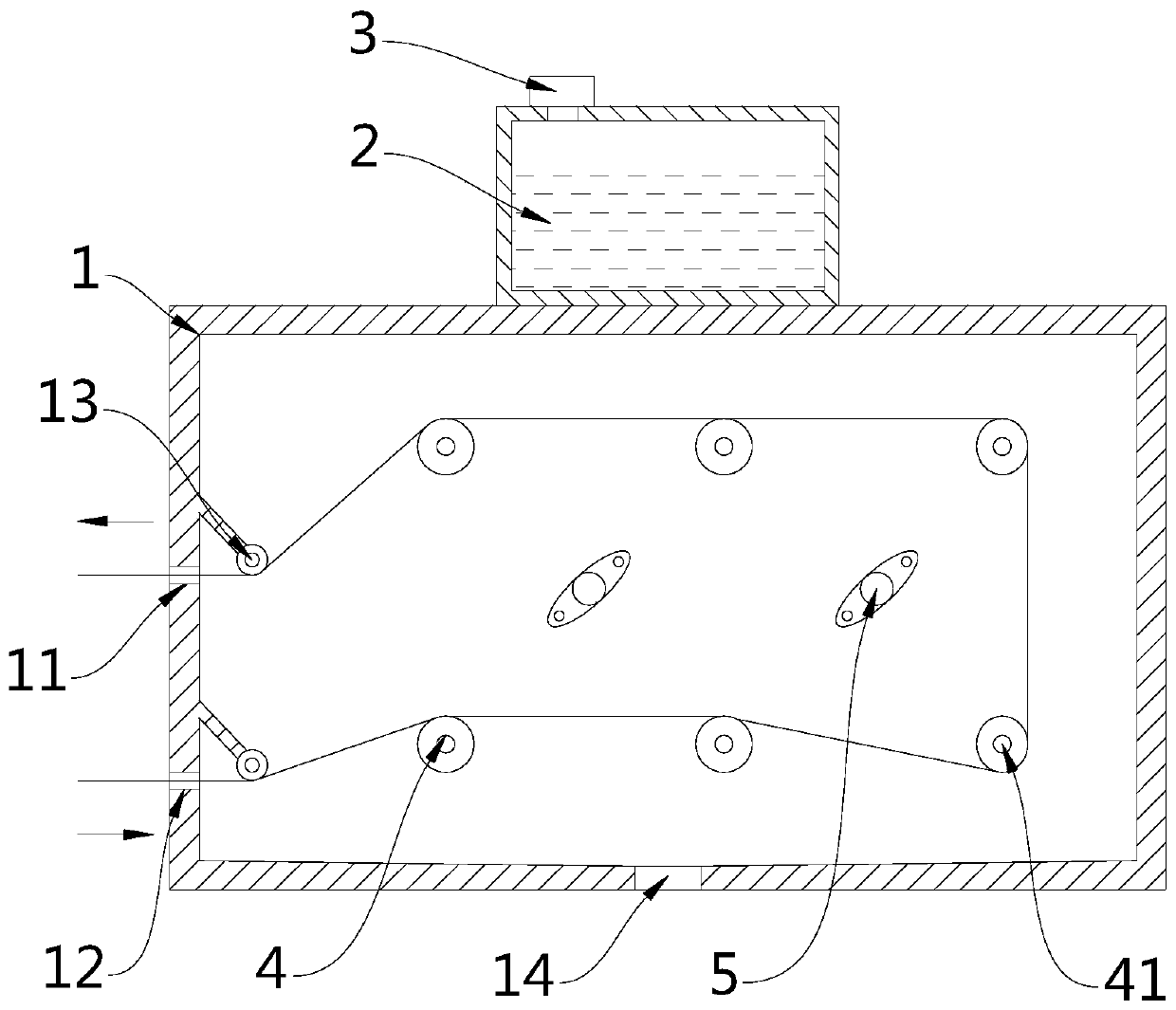

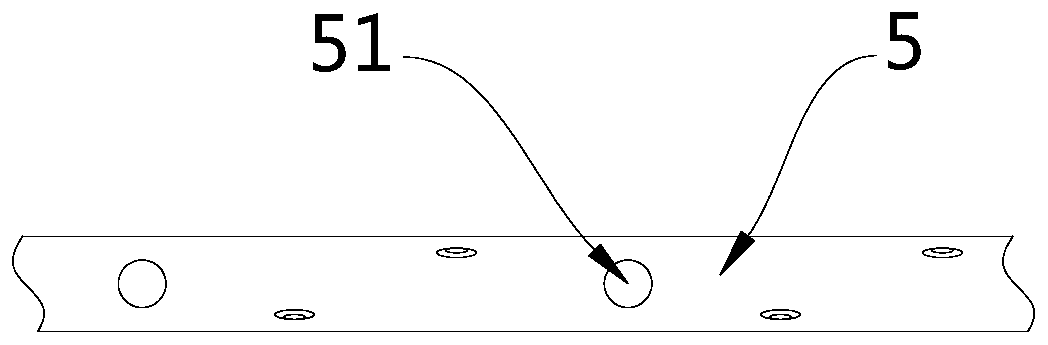

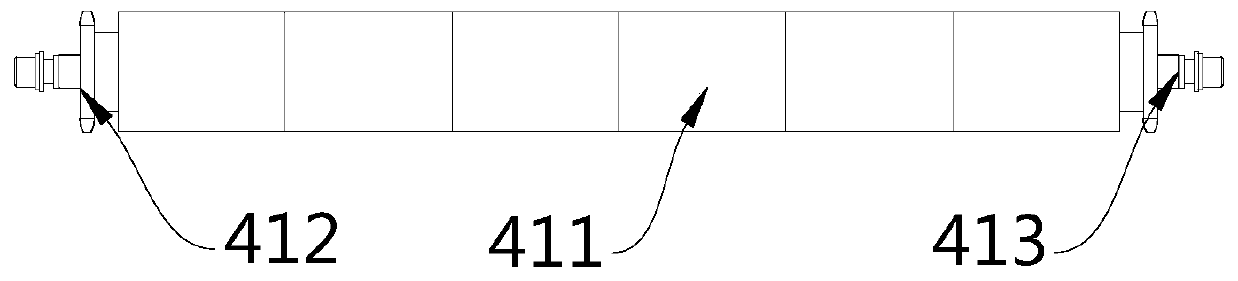

[0028] Embodiment: a kind of moisture supply device of fabric pre-shrinking equipment, the structure is as follows Figure 1 to Figure 8 As shown, it includes a humidity supply box 1, the humidity supply box 1 is connected with a water storage tank 2, and the water storage tank 2 is connected with a steam generator 3, and the upper and lower sides of the same side of the humidity supply box 1 are respectively provided with cloth outlets. 11 and cloth inlet 12, fabrics are realized on the same side and come in and out, and cloth outlet 11 and cloth inlet 12 are provided with guide roller 13 on the inside corresponding to the humidifying box body 1, and the upper and lower two sides are arranged inside the humidifying box body 1. Rows of driving rollers 4, several steam outlet pipes 5 are arranged between the two rows of driving rollers 4, the two end driving rollers 4 far away from the guide rollers 13 in the two rows of driving rollers 4 are corner driving rollers 41, the two r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com