Detachable hollow fiber membrane module

A fiber membrane and hollow technology, applied in the field of detachable hollow fiber membrane modules, can solve the problems of inconvenient industrialization, low plasticity, uneven distribution of air flow field, etc., and achieve the effect of sufficient heat and mass exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

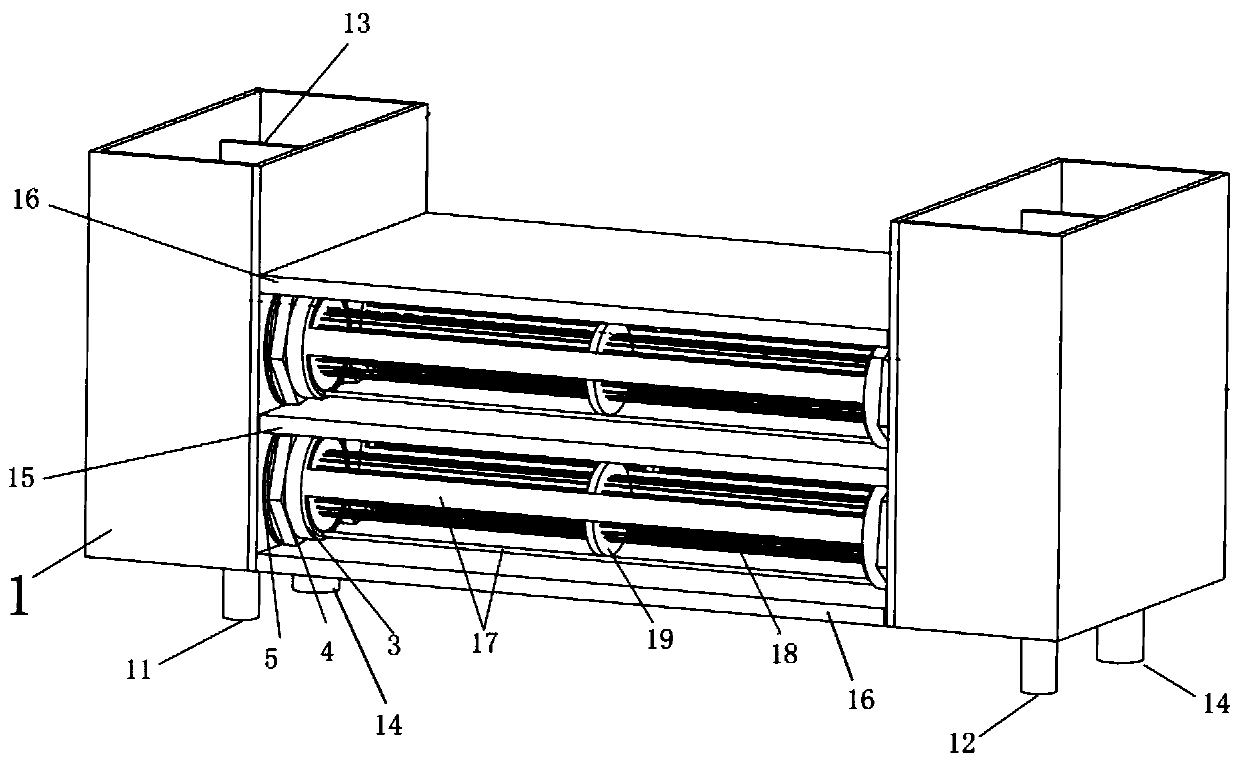

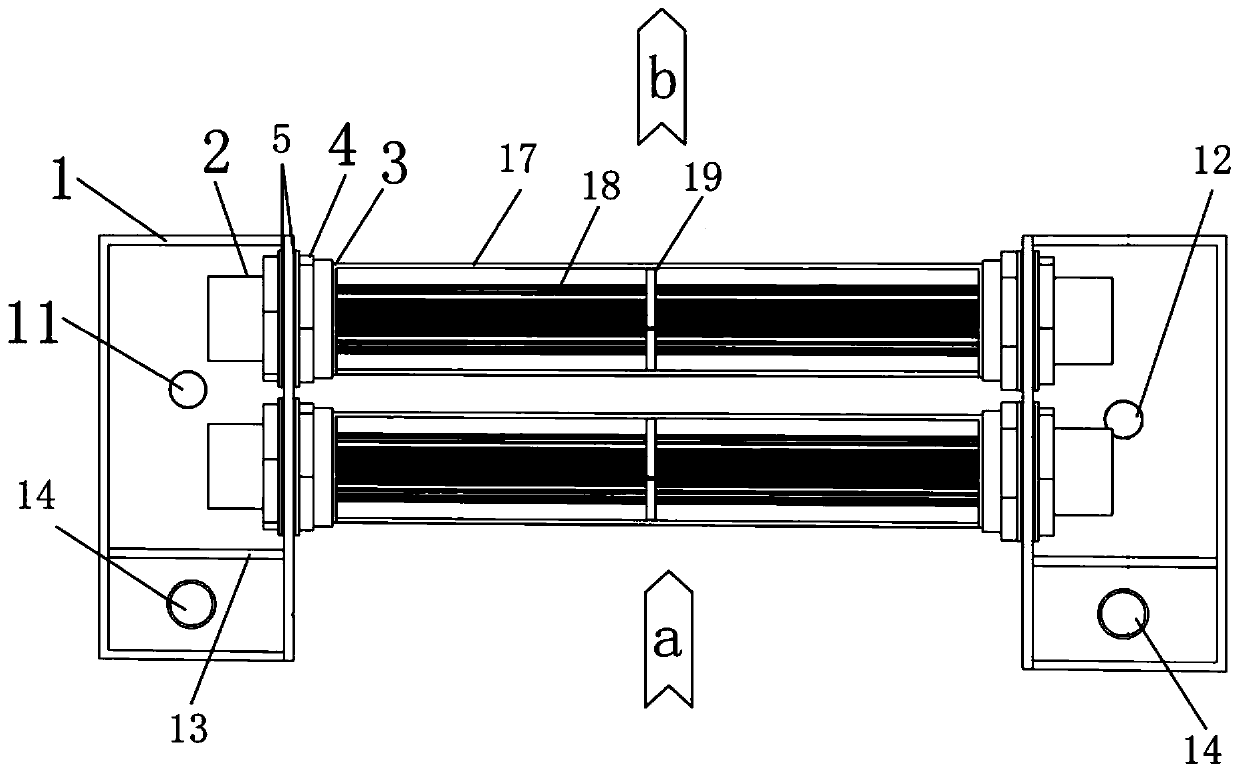

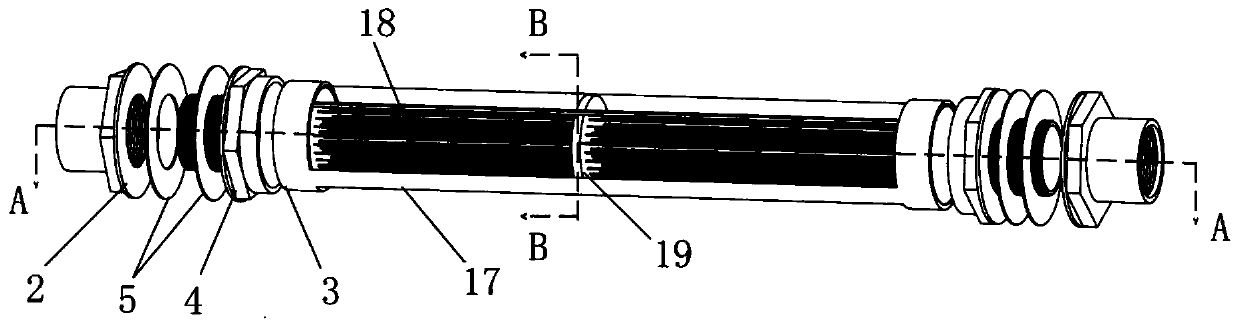

[0040] like figure 1 and 2 As shown, a detachable hollow fiber membrane module includes a solution tank 1, a hollow fiber membrane tube bundle, a first joint 2, a shell 3 and a second joint 4. There are two solution tanks 1, which are respectively opposite to the outer sides of both ends of the hollow fiber membrane tube bundle. The solution tank 1 is filled with cold water or liquid desiccant. The first joint 2 is fixed on the solution tank 1 at a position corresponding to the end of the tube bundle. Both ends of the hollow fiber membrane tube bundle are respectively fixed in different shells 3 . The two ends of the second joint 4 are respectively connected with the first joint 2 and the housing 3 by screws to realize the detachable communication between the tube bundle and the solution tank 1.

[0041] The inner side wall of the first joint 2 is provided with an inner thread, and the outer side wall of the housing 3 is provided with an outer thread. The outer side wall ...

Embodiment 2

[0052] like Figure 8 As shown, a third joint 6, a fourth joint 7, a connecting pipe 8, a valve 9 and a support plate 10 are added, the third joint 6 is screwed to the first joint 2, and the fourth joint 7 is screwed to the For the second joint 4 , two ends of the connecting pipe 8 are respectively connected to the third joint 6 and the fourth joint 7 by screwing. The valve 9 is arranged on the connecting pipe 8 and is used for connecting or disconnecting the connecting pipe 8. The support plate 10 is fixed at the position where the second joint 4 and the fourth joint 7 are connected and are connected to each other. play a supporting role. The first joint 2 , the second joint 4 , the third joint 6 and the fourth joint 7 are respectively provided with polygonal discs that rotate the corresponding joints. Between the joint 2 and the corresponding inner wall of the solution tank 1, between the third joint 6 and the corresponding outer wall of the solution tank 1, between the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com