Vertical pipe evaporative type condensing heat exchanger with repeated water distribution function and heat exchange method thereof

An evaporative condenser and heat exchanger technology, which is applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of making breakthroughs in the heat transfer effect of evaporative condensers, and achieve the technical means that are simple and easy to implement and reduce spraying. Water temperature, increase the effect of disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

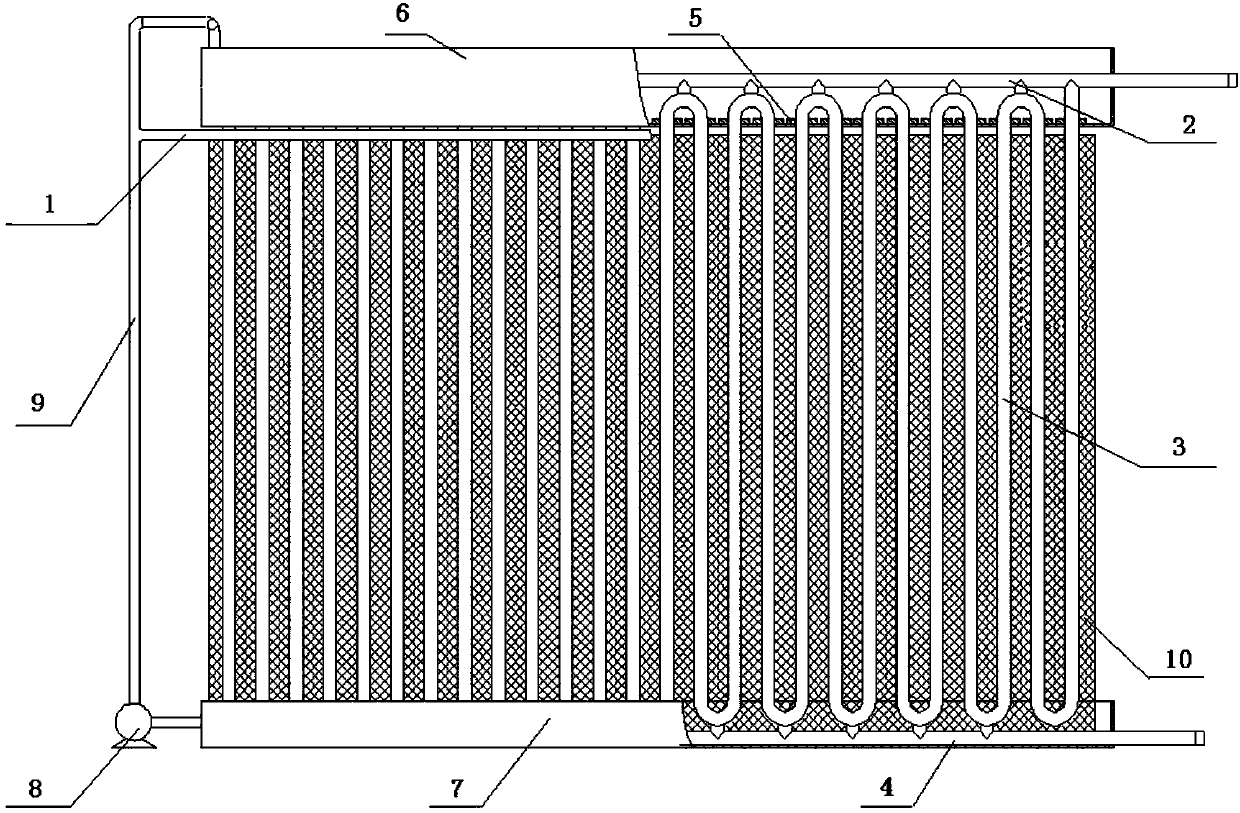

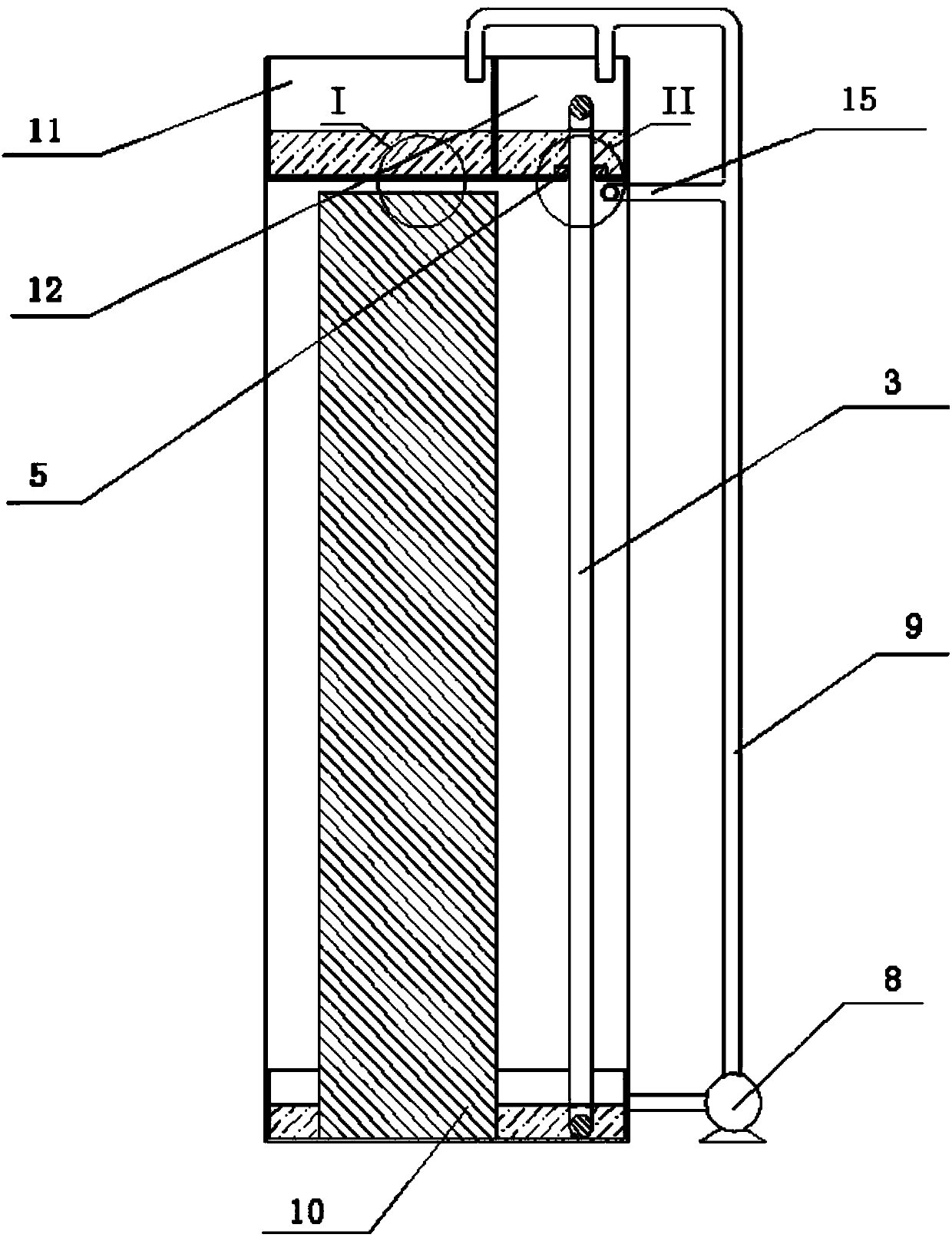

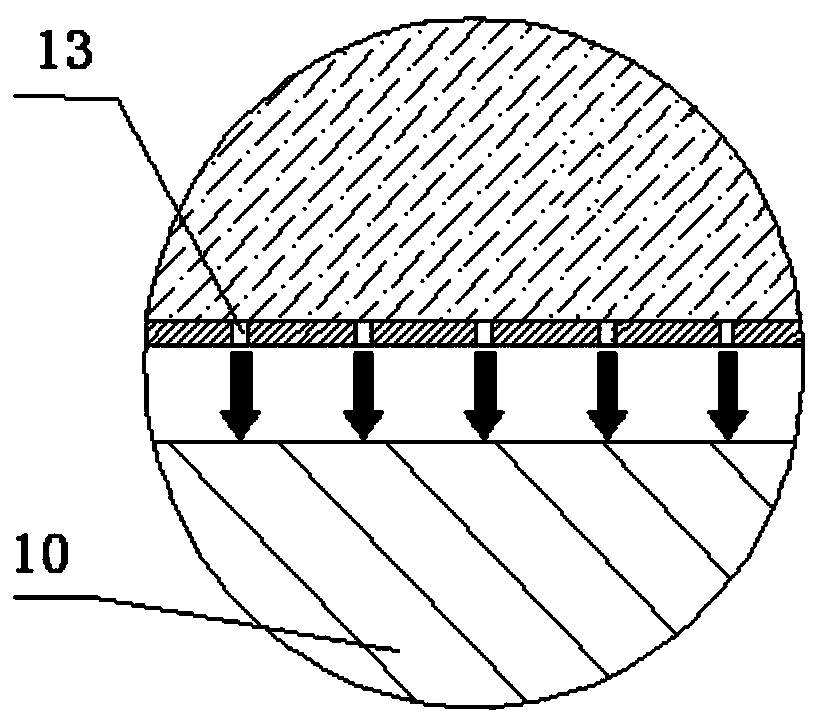

[0031] Such as Figures 1 to 4 shown. The invention discloses a vertical pipe evaporative condensing heat exchanger with multiple water distributions, which comprises an upper gas collecting pipe 2, a lower liquid collecting pipe 4, and vertical condensing heat exchange pipes 3 arranged in a vertical array; the vertical The upper end of the condensing heat exchange tube 3 communicates with the upper gas collector 2, and the lower end communicates with the lower liquid collector 4; the axis of the vertical condensing heat exchange tube 3 is perpendicular to the upper gas collector 2 and the lower liquid collector 4; it is characterized in that: A liquid separator 6 is arranged above the condensing heat exchange tube 3, and a liquid collector 7 is arranged below; the liquid separator 6 divides its interior into a first liquid separator 11 and a second liquid separator 12 through a partition;

[0032] The water below the liquid collecting pan 7 is transported to the first liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com