Ventilated material-guide heat balancing device

A heat equalization and material conduction technology, applied in drying solid materials, lighting and heating equipment, drying and other directions, can solve the problems of high power consumption, small drying driving force, complicated operation, etc., to achieve less power consumption and improve heat exchange. Efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

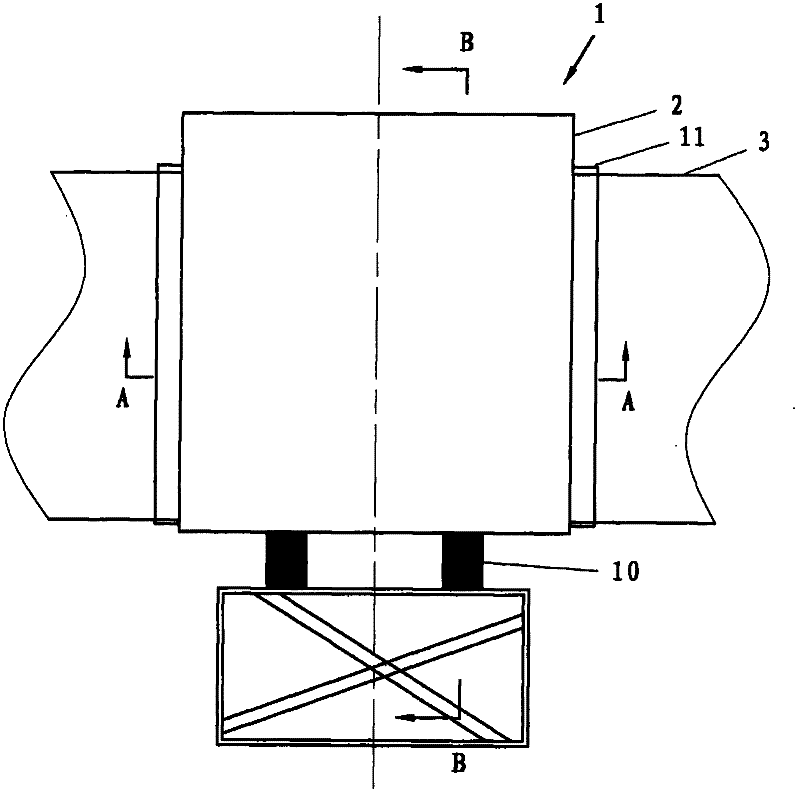

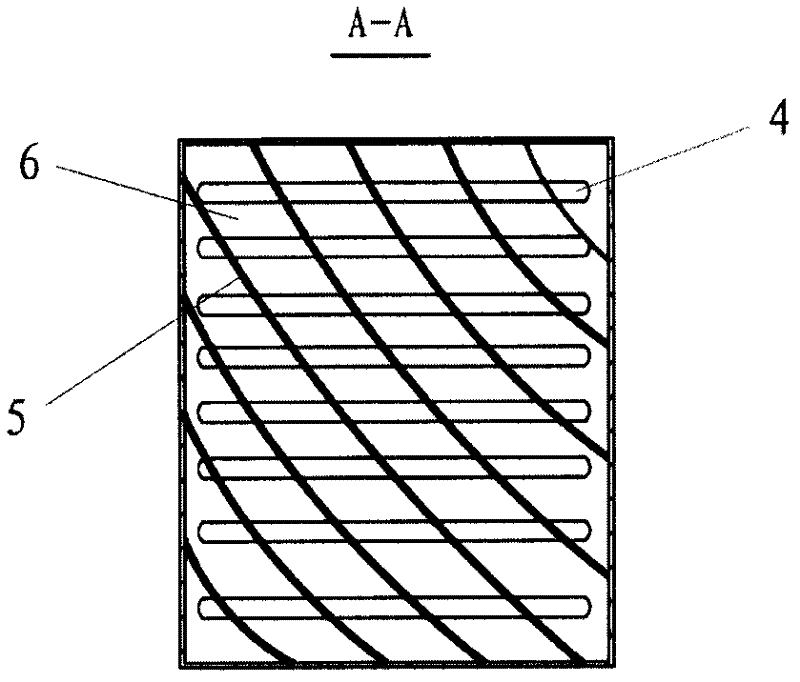

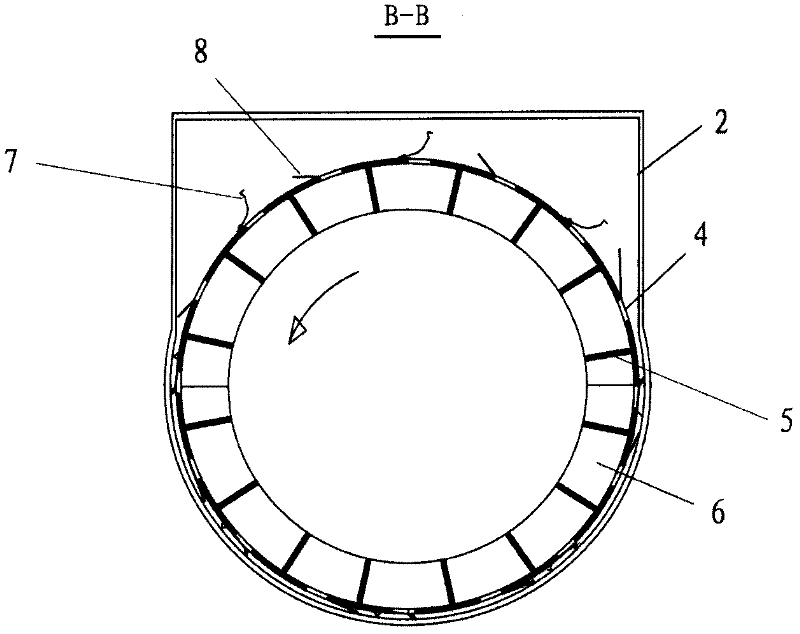

[0018] The heat equalization device for ventilation and material conduction according to the present invention will be described in detail below with reference to the accompanying drawings. The heat equalization device for ventilation and material conduction according to the present invention can be used in combination with a forward drying system or a reverse drying system or both.

[0019] figure 1 Shown is a heat equalization device 1 for ventilated materials according to an embodiment of the present invention. Such as figure 1 As shown, the heat equalization device 1 for ventilation and material includes a box body 2 and a cylinder body 3 passing through the box body 2 . The tank 2 can be sealingly engaged with the cylinder 3 by means of a sealing edge 11 or other sealing means, while allowing the cylinder 3 to rotate relative to the tank 2 . Vents (not shown) are provided on the surface of the case 2 , and the vents may be provided on the upper surface or the side surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com