Device and method enabling multiple sets of crushers to have equal discharging rates

A crusher and discharge volume technology, applied in grain processing and other directions, can solve the problems of the crusher's discharge volume, etc., and achieve the effect of small maintenance and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

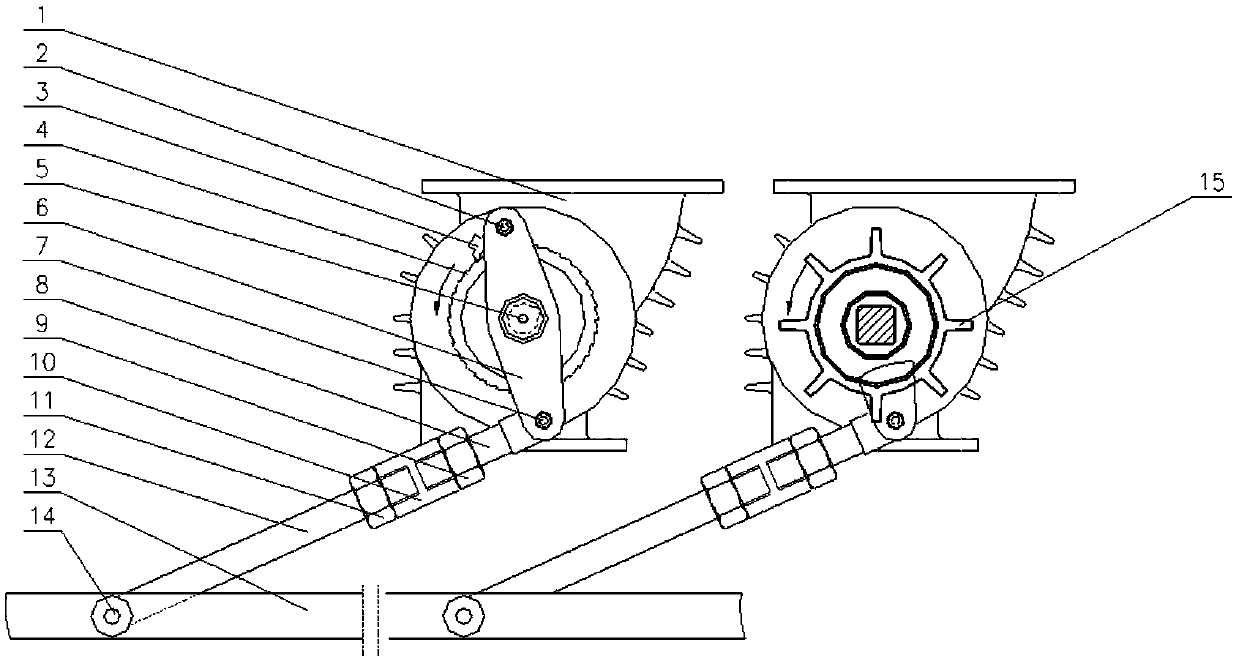

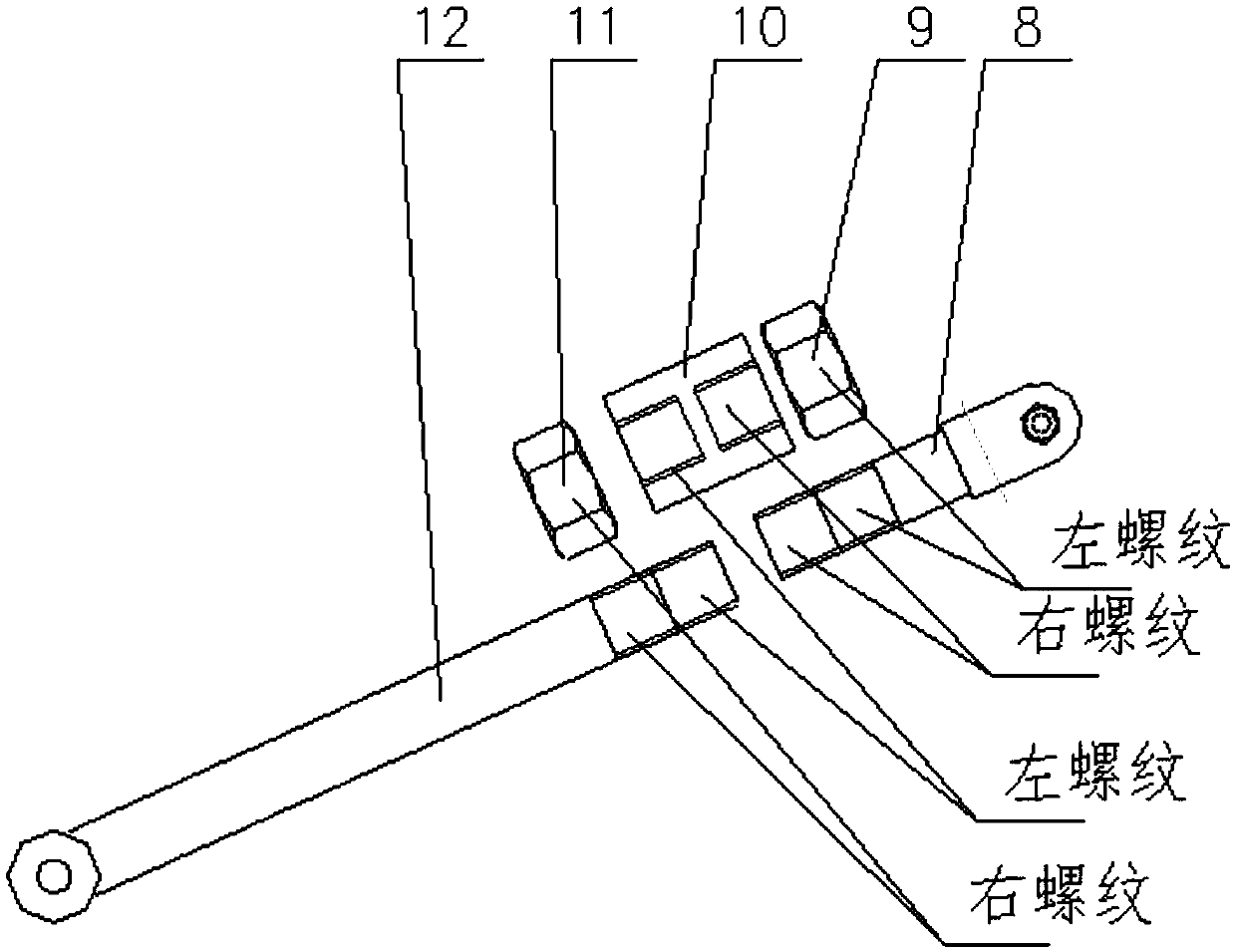

[0016] like figure 1 Shown, this method comprises right push rod 8, first nut 9, middle nut 10, second nut 11 and left push rod 12, and the right end of right push rod 8 is hinged with the bottom of ratchet lever 6 by second bearing pin 7 , the left end of the right push rod 8 is provided with a first nut 9, the left end of the right push rod 8 is connected to the middle nut 10; the left end of the left push rod 12 is hinged with the pull rod 12 through the third pin 14, and the left push rod The right end of 12 is provided with the second nut 11, and the right end of the left push rod 12 is connected with the middle nut 10 to form a push rod with adjustable length; 3 is hinged, the ratchet 3 pushes the ratchet 4 to rotate, the ratchet 4 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com