Automatic steel cylinder cleaning device and operation step thereof

A steel cylinder and cleaning technology, applied in the field of automatic cylinder cleaning devices, can solve the problems of wasting manpower and material resources, inconvenient to use, etc., and achieve the effects of convenient and quick use, improved production efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

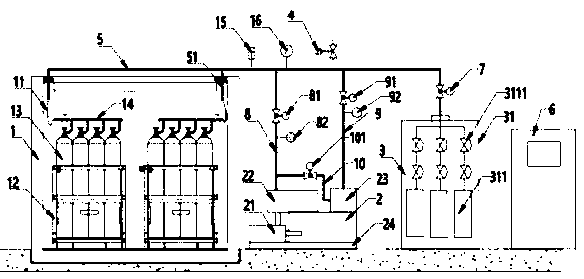

[0026] Depend on figure 1 It is known that a steel cylinder automatic cleaning system device includes a vacuum oven 1, a vacuum unit 2, a replacement gas supply assembly 3, a vent valve 4, a main pipe 5, and a system control cabinet 6; the system control cabinet 6 is provided with a control panel, through The control panel sends work instructions to the PLC controller installed in it, and the PLC controller controls the vacuum oven 1, the vacuum unit 2, the replacement gas supply component 3, and the vent valve 4 to work; one end of the main pipe 5 runs through the top of the vacuum oven 1 and enters Inside the vacuum oven 1, the other end of the main pipe 5 communicates with the output end of the replacement gas supply assembly 3; the main pipe 5 is also provided with an inflation valve 7 for controlling the communication state at the communication place with the replacement air supply assembly 3; the vacuum unit 2 Comprising backing vacuum pump 21, Roots vacuum pump 22 and m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap