Self-lifting mounting method of hoisting tower system

An installation method and self-lifting technology, which can be applied to cranes and other directions, can solve the problems of high lifting height and narrow site, and achieve the effect of reducing safety risks and shortening lifting operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

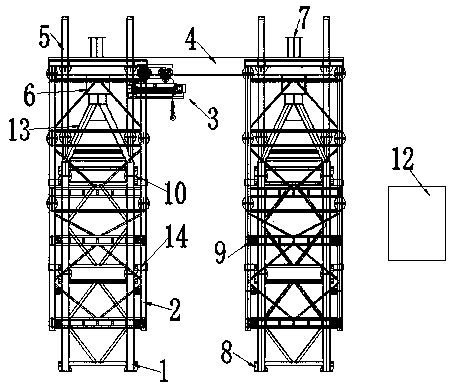

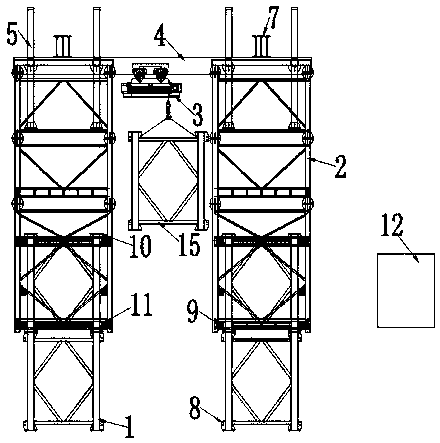

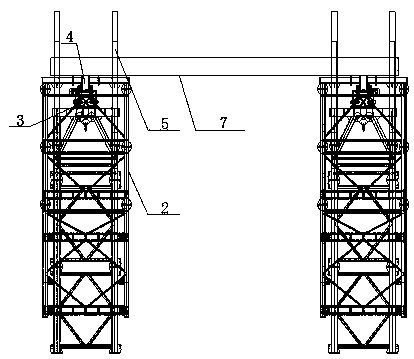

[0035] Embodiment of the present invention: a method for self-elevating installation of a hoisting tower system, as shown in the attached Figure 1-9 As shown, the partial frame bodies of 4 hoisting towers are installed in a square structure on the ground, and a self-elevating jacket frame 2 is socketed on the outside of each frame body of each hoisting tower, and 2 sets of 2 self-elevating jacket frames 2 The tops are connected via electric hoist track beams 4, and the tops of 2 groups of 2 self-elevating coat racks 2 arranged horizontally are connected via lifting beams 7 on which lifting equipment is installed. Since the height of part of the hoisting tower installed earlier is only about 9m, far below the design height, it is necessary to increase the height of the hoisting tower. The way of he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com