Subgrade seepage and drainage blind ditch

A technology for seepage and drainage and subgrade, which is applied in roads, infrastructure engineering, rails, etc. It can solve the problems of water-absorbing materials being deformed by pressure, uncontrollable construction quality, and a large number of constituent materials, so as to achieve good water permeability, improve assembly construction efficiency, and structure high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is introduced below by accompanying drawing.

[0023] In this application, it should be noted that the direction along the extension of the subgrade seepage blind ditch is defined as the longitudinal direction, and the width direction away from or close to the subgrade seepage blind ditch is defined as the transverse direction.

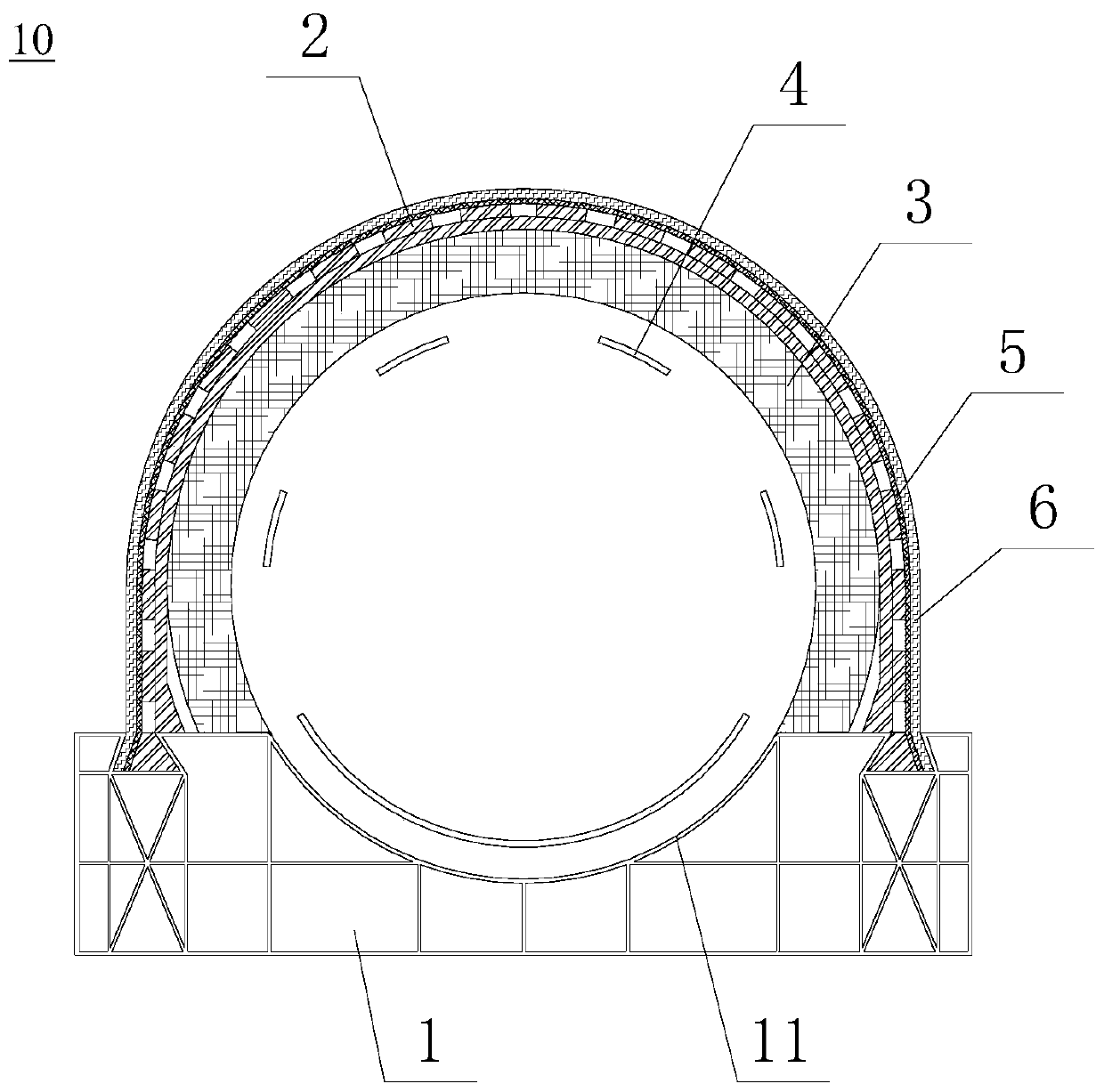

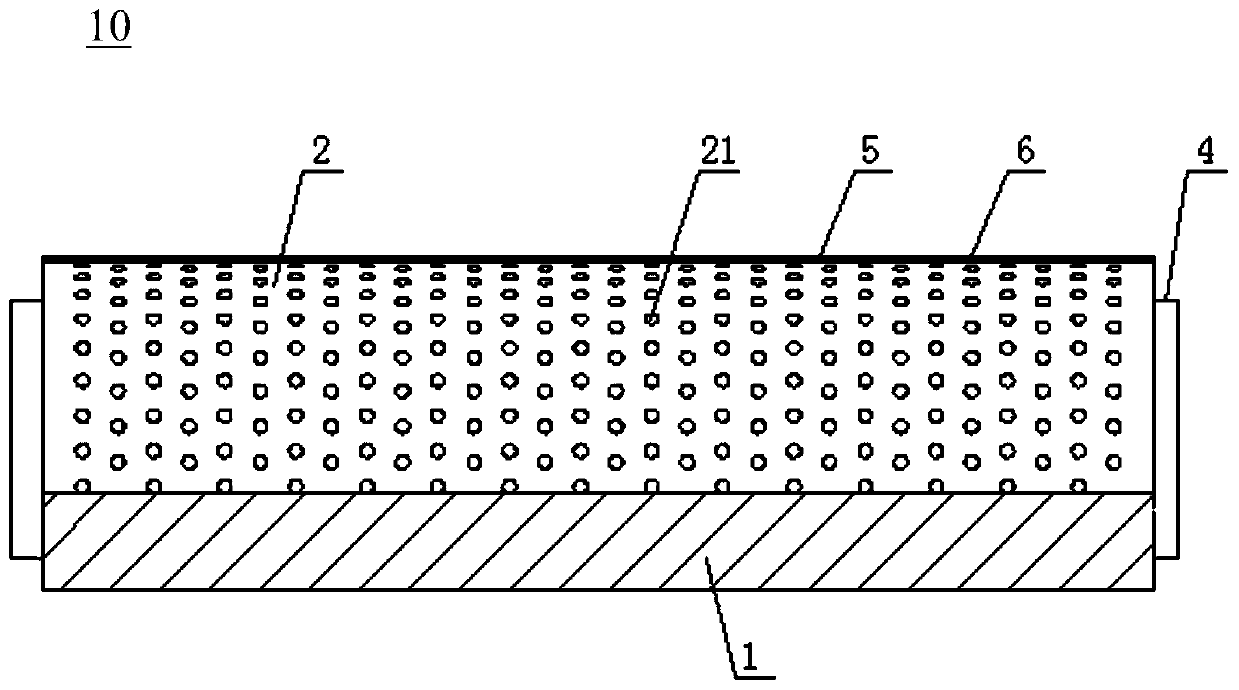

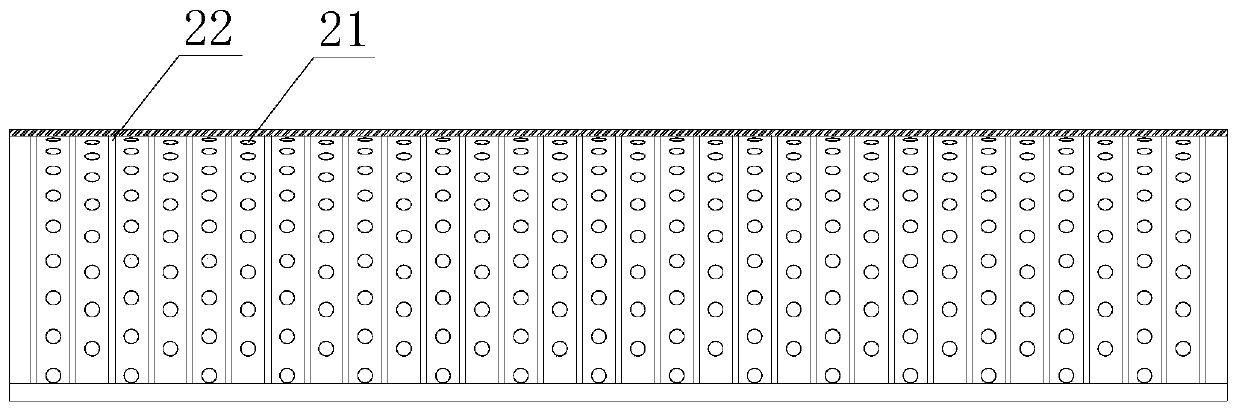

[0024] figure 1 The cross-sectional structure of the roadbed seepage drainage blind ditch 10 according to the present invention is shown. Such as figure 1 As shown, the subgrade seepage drainage blind ditch 10 includes a base 1 and a frame body 2 assembled with the base 1 . The base 1 is arranged on the base of the roadbed, and is laid along the longitudinal extension of the roadbed, and the frame body 2 is installed and connected to the upper part of the base 1 . In one embodiment, the base is made of PVC material (rigid polyvinyl chloride). The base 1 has good stability, and the installation and connection between ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com