Gas pipeline embedding system and method

A technology of gas pipelines and hidden burial, which is applied in the direction of combustion methods, combustion equipment, fuel supply, etc., can solve the problems of construction difficulty and construction period increase, increase construction cost, hidden safety hazards, etc., to save pipeline length and construction intensity, reduce Small slot area, the effect of protecting the load-bearing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

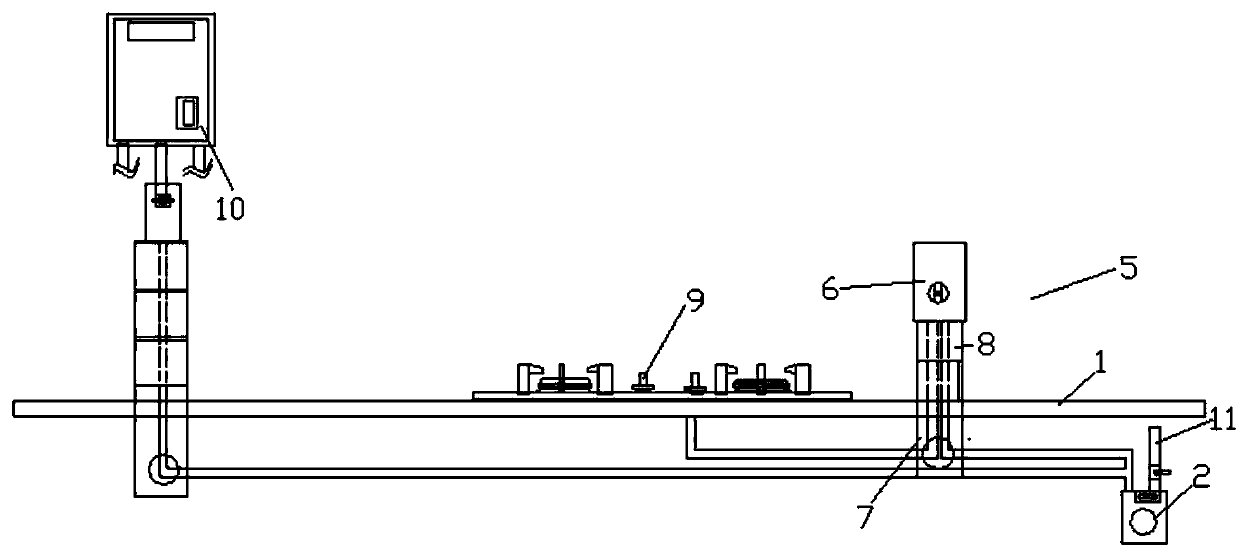

[0018] Example: such as figure 1 As shown, it includes a gas riser 11, the gas riser 11 is connected to the gas meter 2, the top of the gas meter 2 is provided with a cabinet top plate 1, and the gas meter 2 is connected to the gas delivery pipe and the water heater gas delivery pipe, and the gas meter 2 The relative position of the left part is provided with a plurality of buried grooves 7, the gas meter 2 rear is provided with a wall 5, the rear side of the cabinet top plate 1 is in contact with the front side of the wall 5, and the hidden grooves 7 sink to the inside of the wall 5 to a certain extent. Depth, the top of the buried groove 7 is higher than the top plate 1 of the cabinet, the bottom of the buried groove 7 is lower than the top plate 1 of the cabinet, the gas delivery pipe enters the inside of the buried groove 7 and passes through the top plate 1 of the cabinet through the buried groove 7, and the top of the gas delivery pipe Connect to the buried valve 6 in fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com