Double fork type enhanced mixed smoke gas denitration device

A fork type, flue gas technology, applied in the field of flue gas denitrification, can solve the problems of increasing investment cost, increasing system operating cost, unsatisfactory mixing effect, etc., to achieve the effect of saving cost, saving mixing length and time, and improving denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

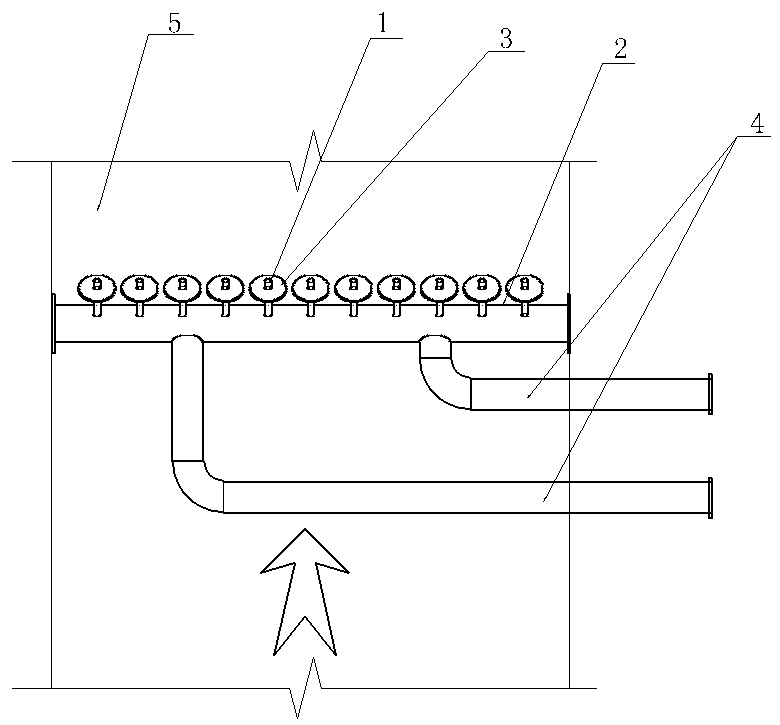

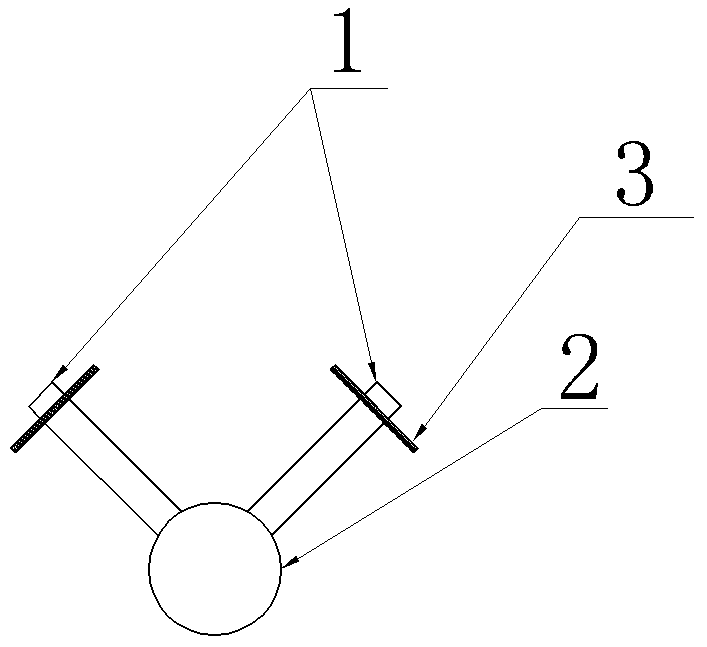

[0016] As shown in the figure, a two-fork type enhanced mixed flue gas denitrification device includes a flue 5 and an ammonia spray grid main pipe 4. The flue 5 is vertically arranged, and the flue 5 is provided with horizontal spray Ammonia grid branch pipe 2, ammonia injection grid branch pipe 2 is connected with ammonia injection grid main pipe 4, several groups of nozzles 1 are arranged at fixed intervals on the upper part of ammonia injection grid branch pipe 2, each group of nozzles 1 is two, divided Both sides are inclined upward at a certain angle with the vertical direction, and the upper end of the nozzle 1 is provided with a spoiler 3, and the spoiler 3 is circular, and the diameter of the spoiler 3 is 100-500mm. 3 is located at a distance of 10-20mm from the nozzle mouth, the lower bottom surface of the spoiler 3 is provided with a high tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com