Detection device for angle of cut surface of single crystal silicon rod and square opening machine

A single crystal silicon rod and angle detection technology, which is applied in the direction of measuring devices, measuring angles, fine working devices, etc., can solve problems such as the deviation of verticality of the cutting surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

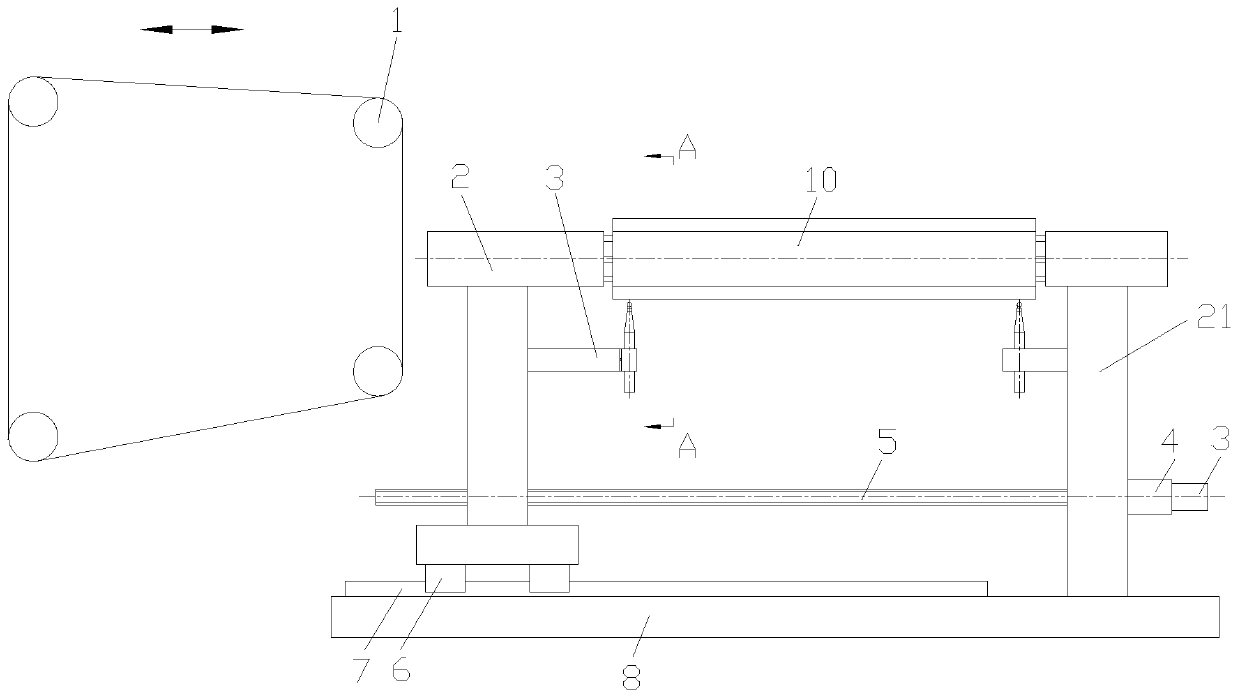

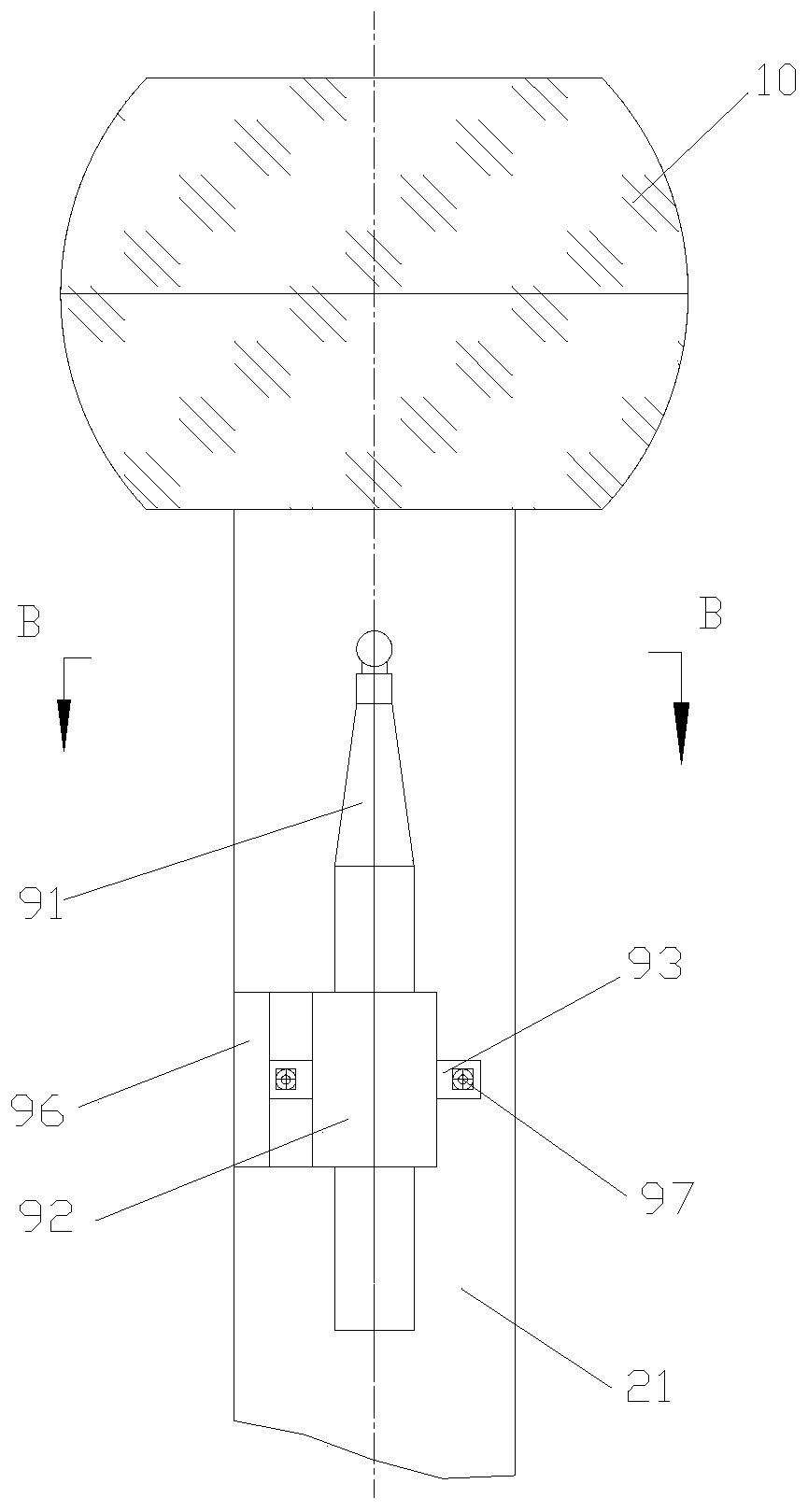

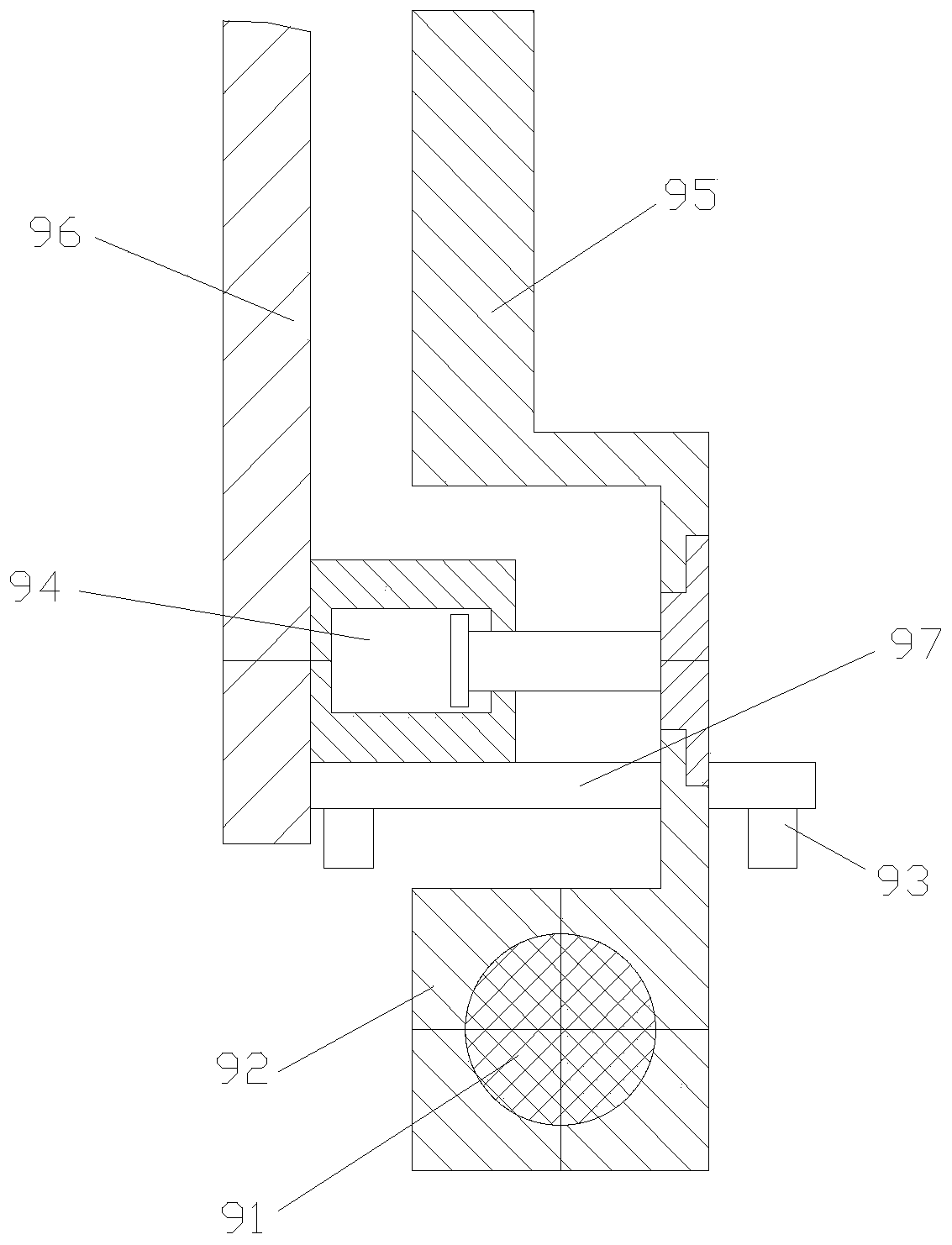

[0031] see Figure 1 to Figure 3 , the present invention provides a single crystal silicon rod cutting surface angle detection device 9, which is used for sensors used to scan the shape characteristics of the single crystal silicon rod 10 in the auxiliary square root machine, and jointly scan the shape characteristics of the single crystal silicon rod 10, To provide information for the alignment of the crystal line of the single crystal silicon rod 10, but it is mainly used to detect the cut surface of the single crystal silicon rod 10 after the alignment of the central axis of the single crystal silicon rod 10 and the clamping mechanism 2 is completed Whether it is in a horizontal state provides a criterion for judging whether the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com