Terminal structure of guillotine-type connector

A terminal structure and connector technology, which is applied to the parts, connections, fixed/insulated contact components of the connection device, etc., can solve the problems of poor contact, insufficient clamping force, insufficient conductive effect and allowable current size, etc., to achieve Effect of lowering insertion resistance and reducing frictional wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

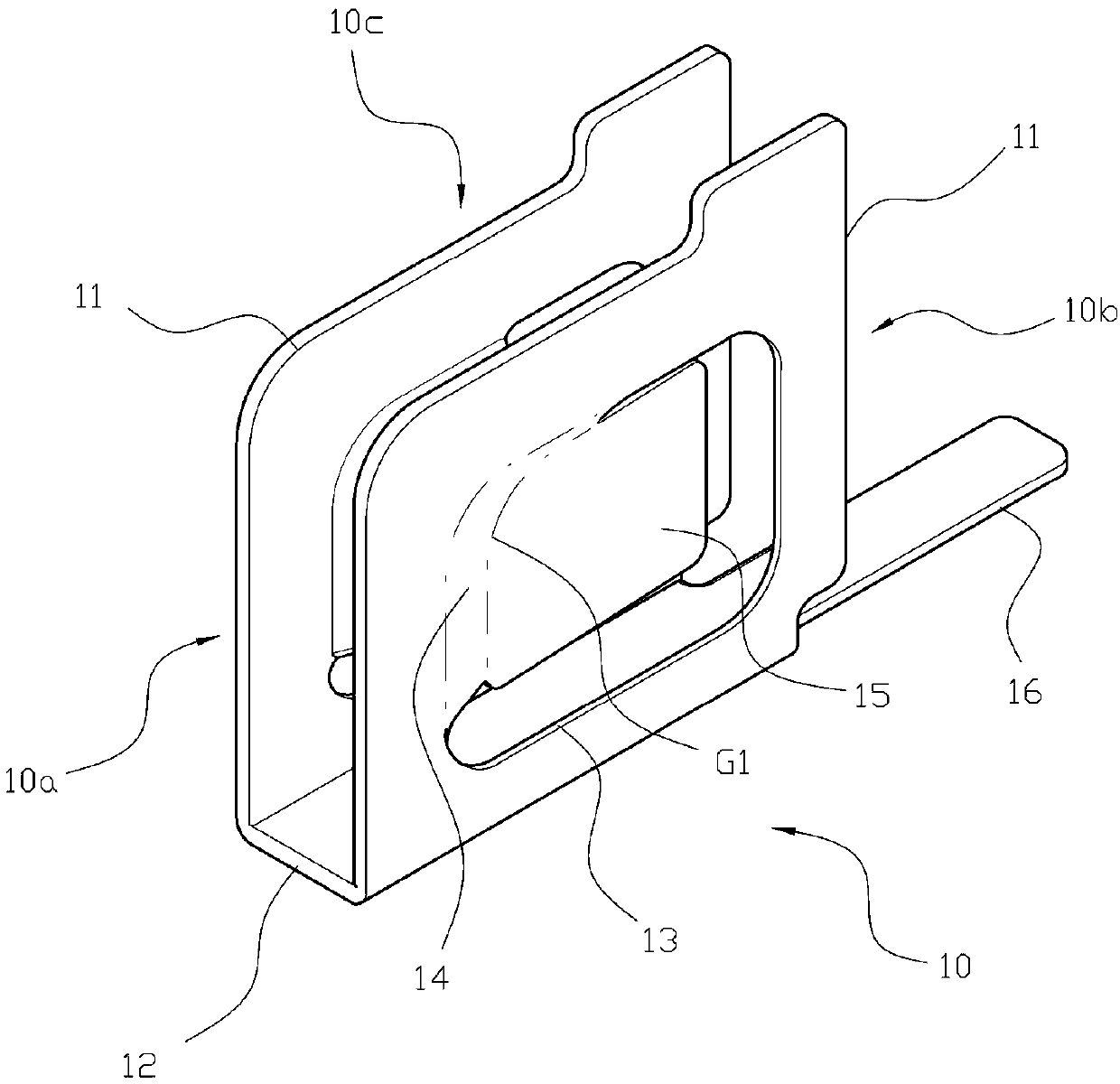

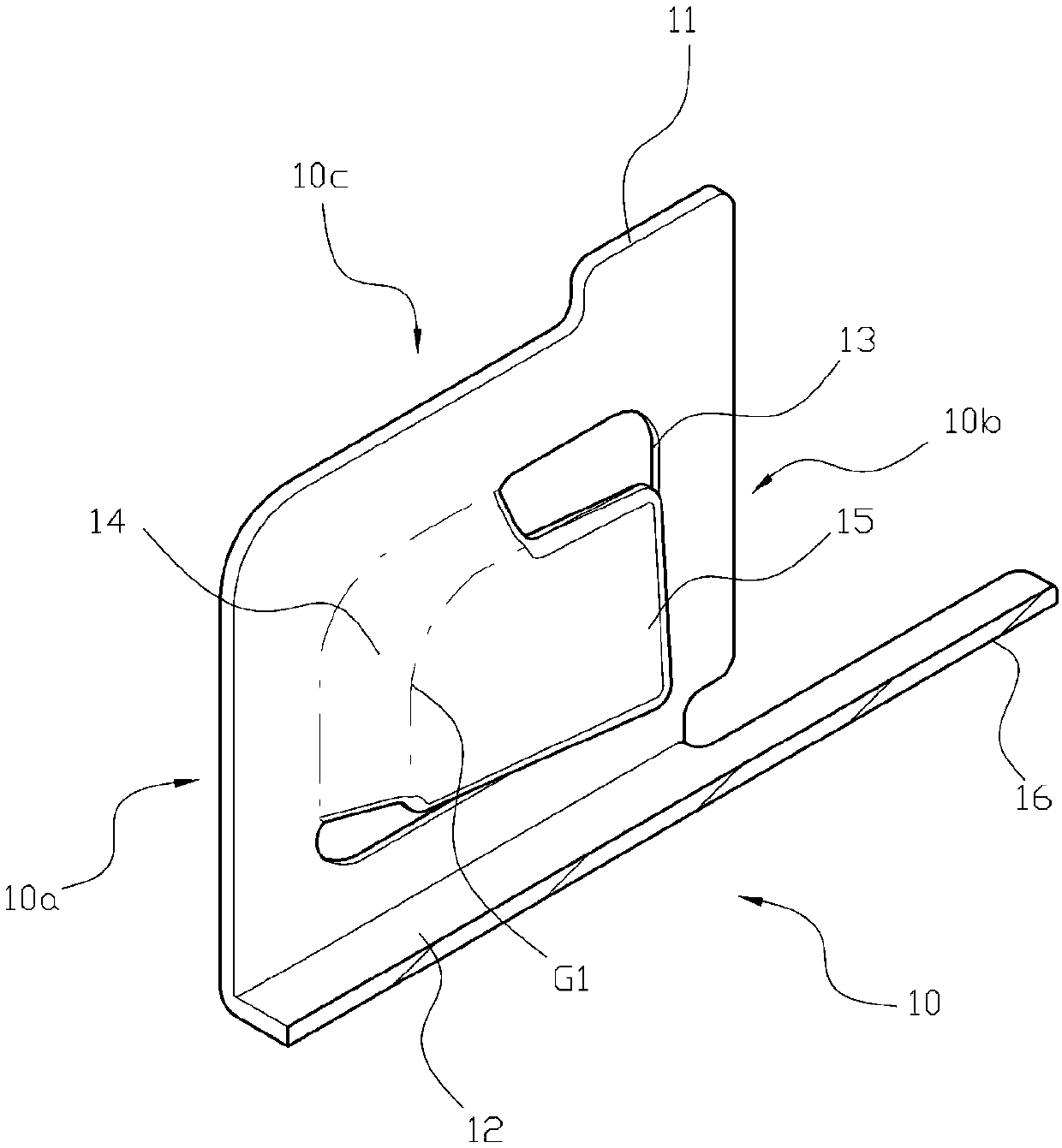

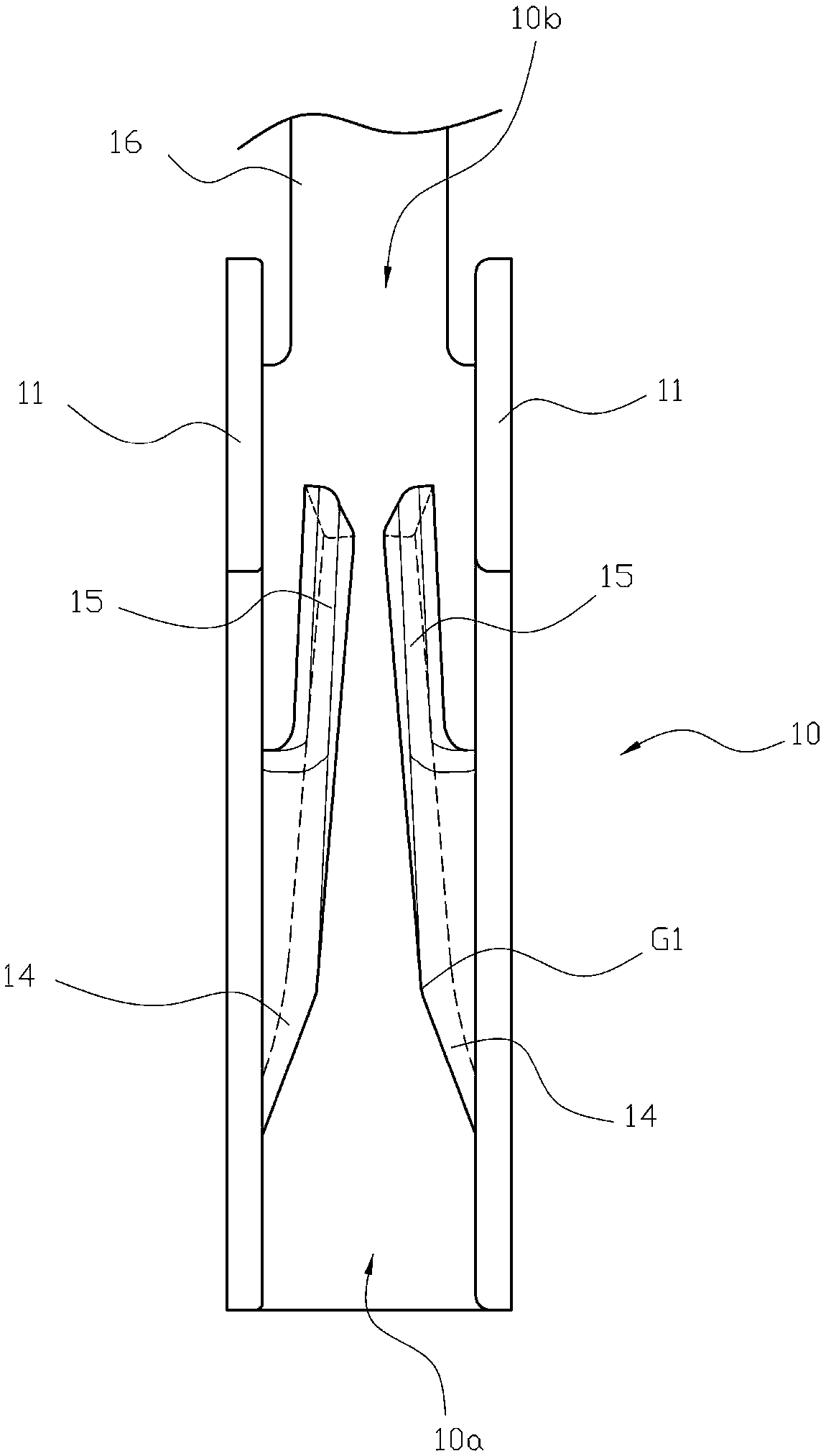

[0080] first please figure 1 Continuous to Figure 4 As shown, a terminal structure of a knife-type connector includes: at least one first terminal 10, the first terminal 10 is provided with two plates 11 in parallel, and the two plates 11 are arranged at intervals, and are formed by two A front insertion end 10a and an insertion end 10b are formed at intervals between the plates 11. A bottom plate 12 is connected between the two plates 11, and the first terminal 10 is provided with the bottom plate 12. An upper insertion end 10c is formed at the opposite end of the upper insertion end 10c, and a square opening 13 is provided on the two plates 11, and the square opening 13 of the plate 11 is integrally connected with the edge of the upper insertion end 10c adjacent to the front insertion end 10a. The arc portion 14 protruding inside forms the first clamping position G1 by the shortest distance between the two arc portions 14, and the two arc portions 14 are connected with fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com