Chemical liquid shunting spiral hedging mixer

A technology for chemical liquids and mixers, applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of complex structure, large volume, high energy consumption, etc., and achieve the effect of improving the mixing effect and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

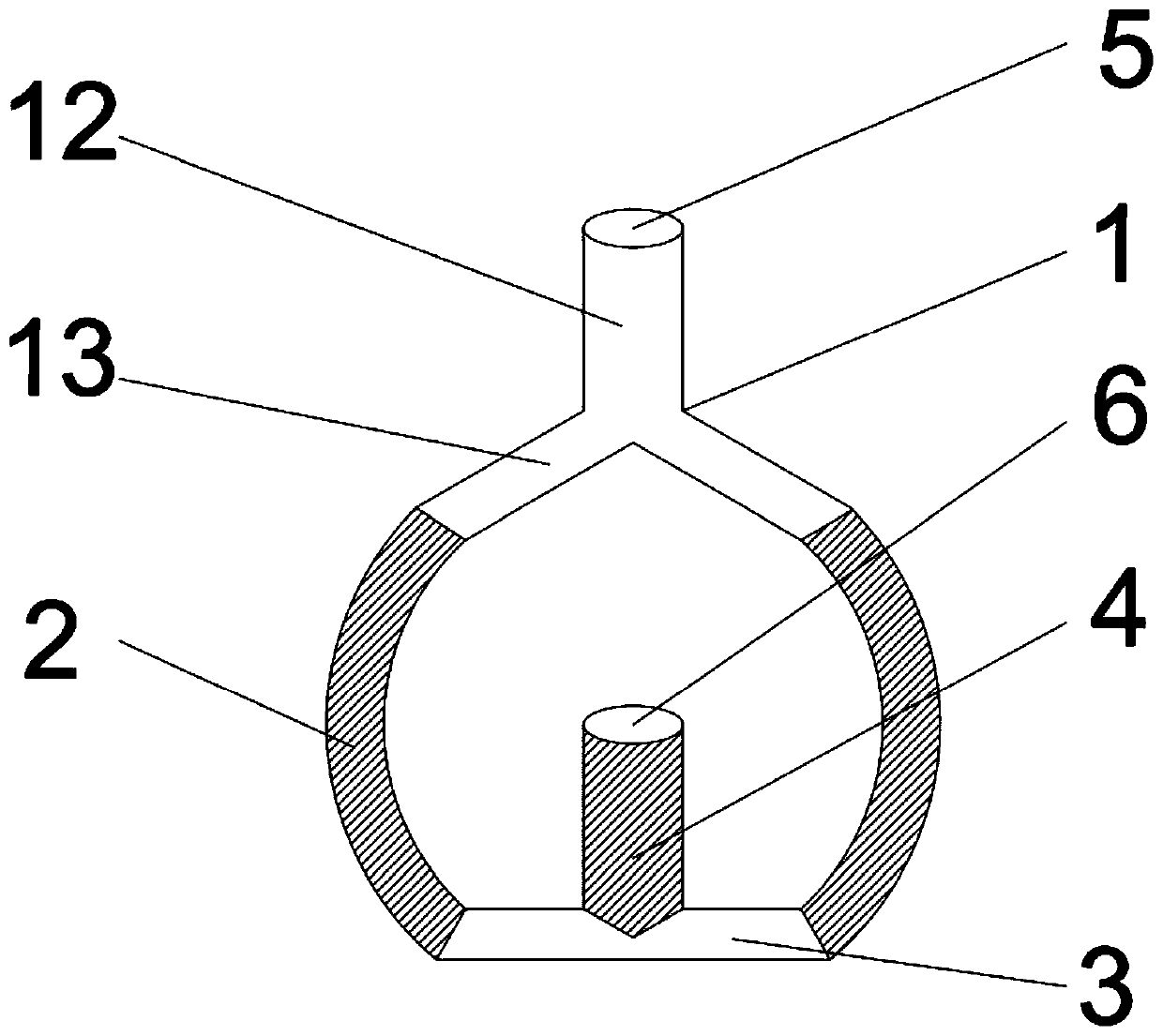

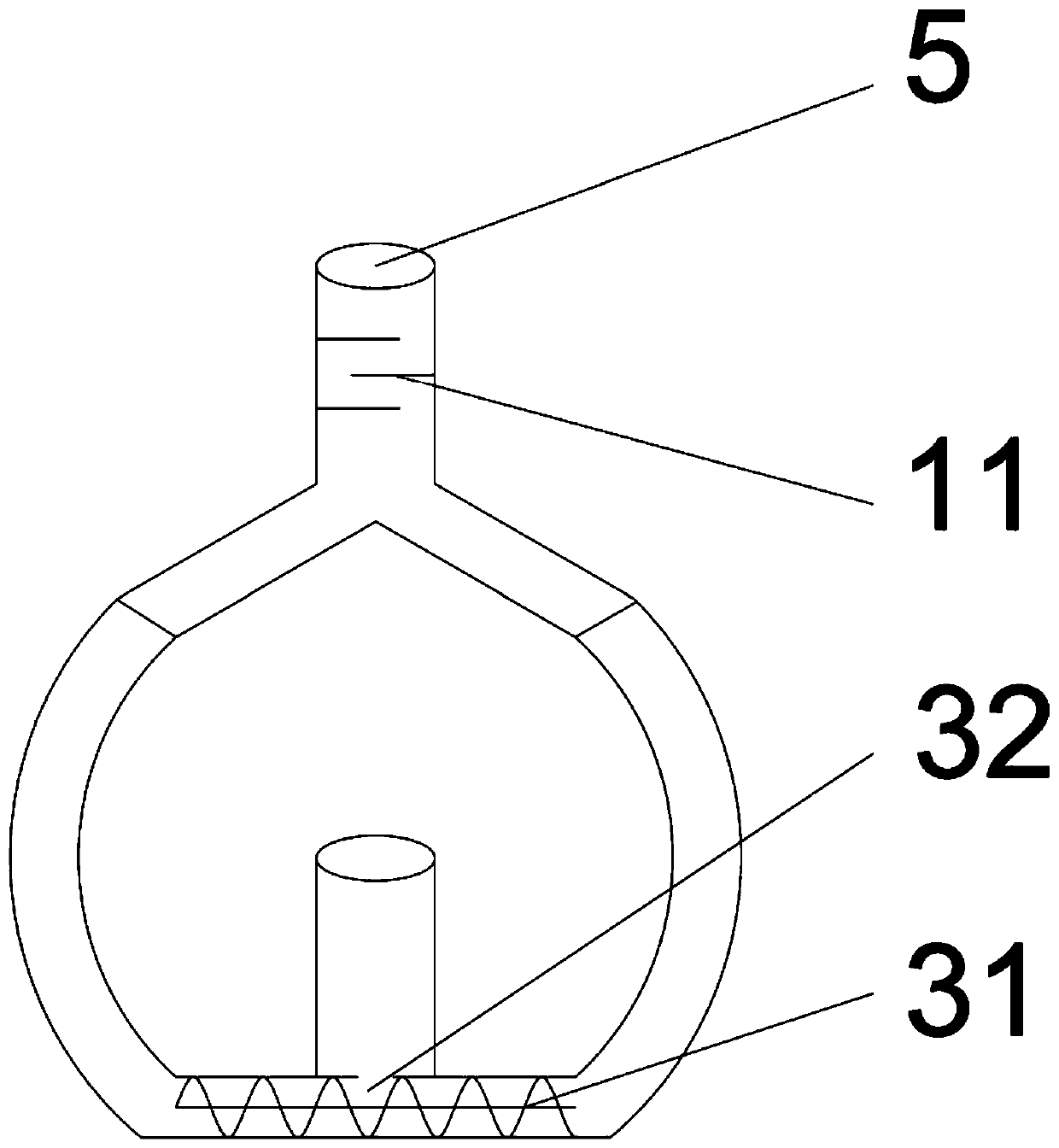

[0024] like Figure 1-2 As shown, a chemical liquid diversion spiral hedging mixer, comprising a material diversion pipe 1, two diversion pipes 2, a spiral hedging mixing pipe 3, and a discharge pipe 4 connected in sequence, is characterized in that: the material diversion pipe 1 includes a main pipe 12 and two branch pipes 13; the ends of the branch pipes 13 are connected to a diversion pipe 2, and the other end of the diversion pipe 2 is connected to the left or right end of the spiral hedging mixing pipe 3; the spiral hedging mixing pipe 3 At least one draft pipe 2 is connected to both ends; the middle part of the spiral hedging mixing pipe 3 is connected to a finished product discharge pipe 4 .

[0025] Further, spoilers 11 are arranged in a staggered manner inside the main pipe 12 of the material distribution pipe 1 ; the top of the material distribution pipe 1 is a material inlet 5 .

[0026] Further, the guide pipe 2 is an arc-shaped pipe.

[0027] Further, spiral fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com