Static mixing device for silicone adhesive production

A static mixing device, a technology for silicone rubber, applied in fluid mixers, mixers, shake/oscillation/vibration mixers, etc., can solve the troublesome mixing process, lack of premix components, and affect the raw materials for silicone rubber production. Overall mixing efficiency and other issues to achieve the effect of improving overall mixing efficiency and improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

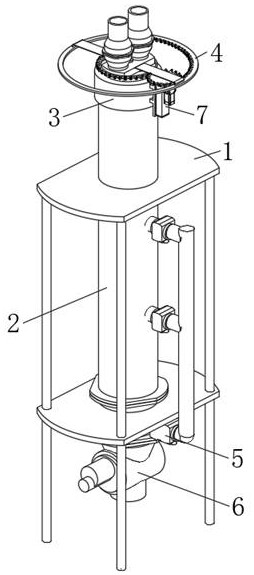

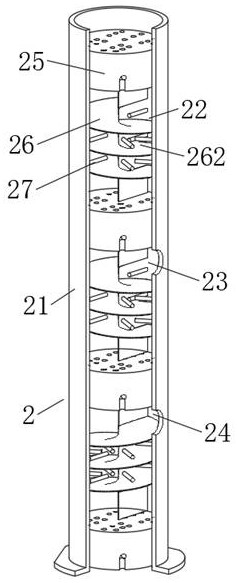

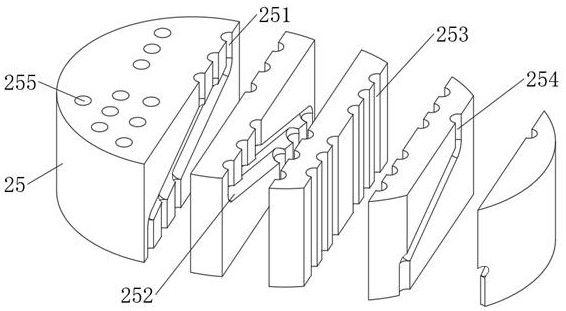

[0029] Example: as Figure 1-8 As shown, the present invention provides a static mixing device for silicone rubber production, including a support frame 1, a static mixing mechanism 2 is fixedly clamped on the top of the support frame 1, and a premixing component 3 is arranged on the top of the static mixing mechanism 2. The outer side of the component 3 is provided with a driving component 4, the outer side of the premixing component 3 is provided with a driving motor 7, the bottom end of the static mixing mechanism 2 is fixedly installed with a cycle inspection component 5, and the bottom end of the cycle inspection component 5 is fixedly installed with a material control valve 6.

[0030] The premixing assembly 3 includes a premixing outer frame 31 and a premixing frame 32. Two premixing pipes 33 symmetrically distributed are fixedly clamped in the premixing frame 32. The top of the premixing pipe 33 is fixedly installed with a feeding pipe through a flange. 34. When in us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com