Special pesticide applying machine

A technology of applicator and pesticide, which is applied to the device, application, and weed eradication device for catching or killing insects, etc. It can solve the problem that the uniform mixing of water and pesticide cannot be realized, the operation effect such as weeding is affected, and the purity of pesticide is affected. problems, to avoid the impact on personal health, improve work efficiency, and have the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

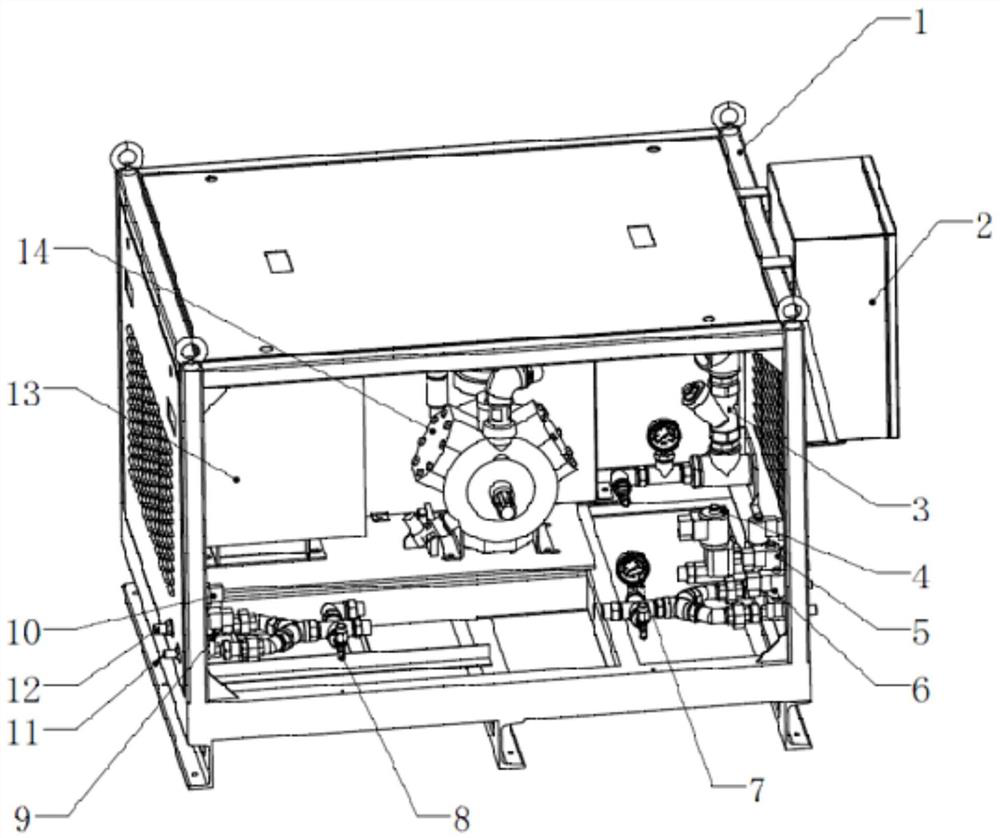

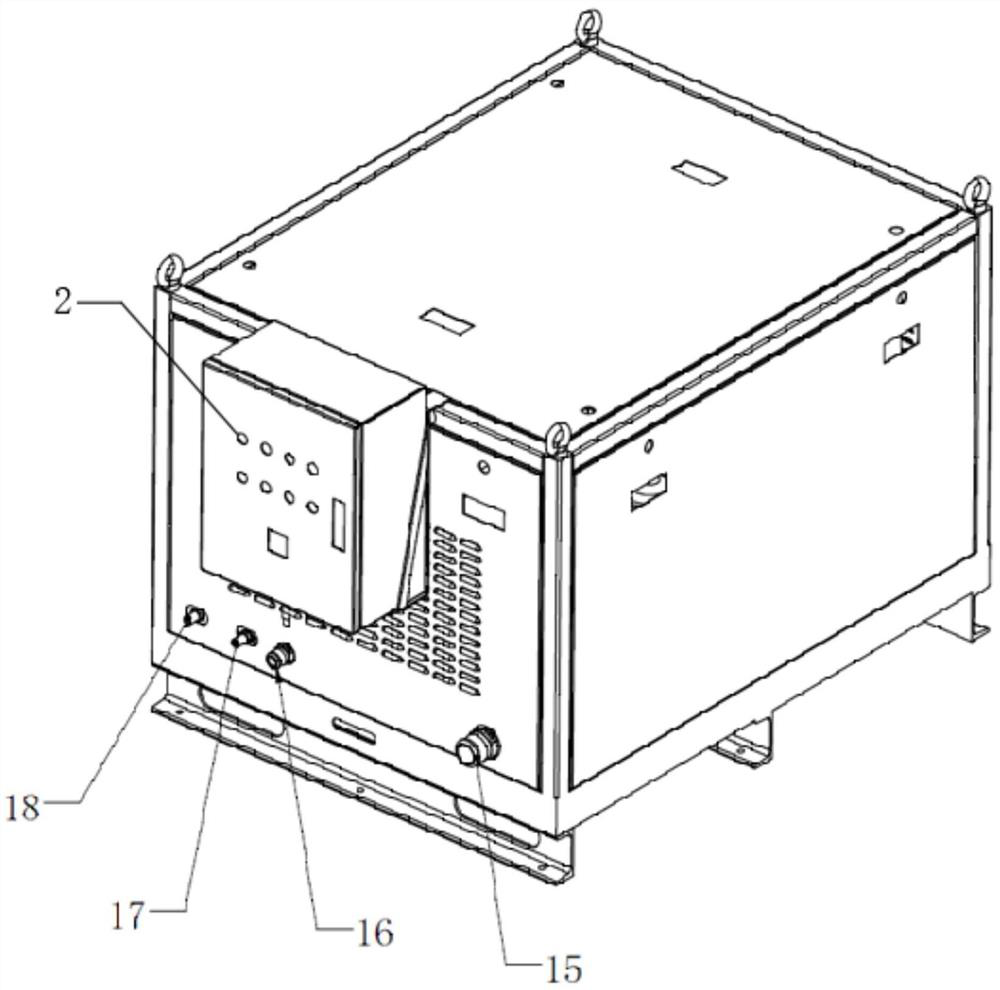

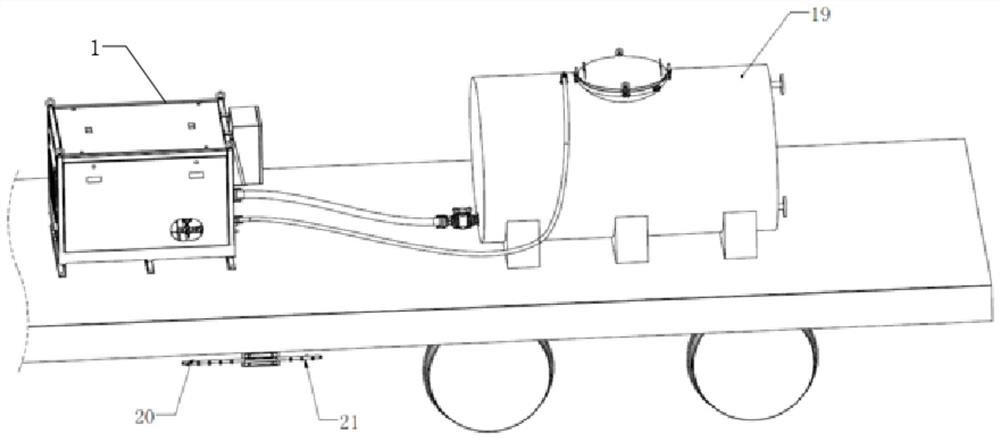

[0027] refer to Figure 1-4 , is the special pesticide applicator disclosed by the present invention, comprising the equipment main frame 1 and the body assembly plate (not labeled in the figure), the bottom of the body assembly plate is equipped with rollers, and the equipment main frame 1 is fixed on the top of the body assembly plate by bolts On one side, the inside of the main equipment frame 1 is provided with an outlet valve assembly, a filter 3, a water return valve 4, a pressure gauge 7, an overflow valve 8, a generator 13 and a motor pump unit 14, and outside the main equipment frame 1 there is a The bottom edge of the side is provided with branch three water outlets 11 and branch four water outlets 12, and the bottom edge of the other side of the main frame 1 of the equipment is provided with a water inlet 15, a water return port 16, and a branch on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com