Modular profile steel combination type machine vise

A combined and modularized technology, which is applied in the direction of metal processing machinery parts, clamping, supporting, etc., can solve the problems of taking up a lot of space, adjusting the friction force, and long cycle, so as to improve the utilization rate, reduce the friction force, reduce the The effect of processing fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

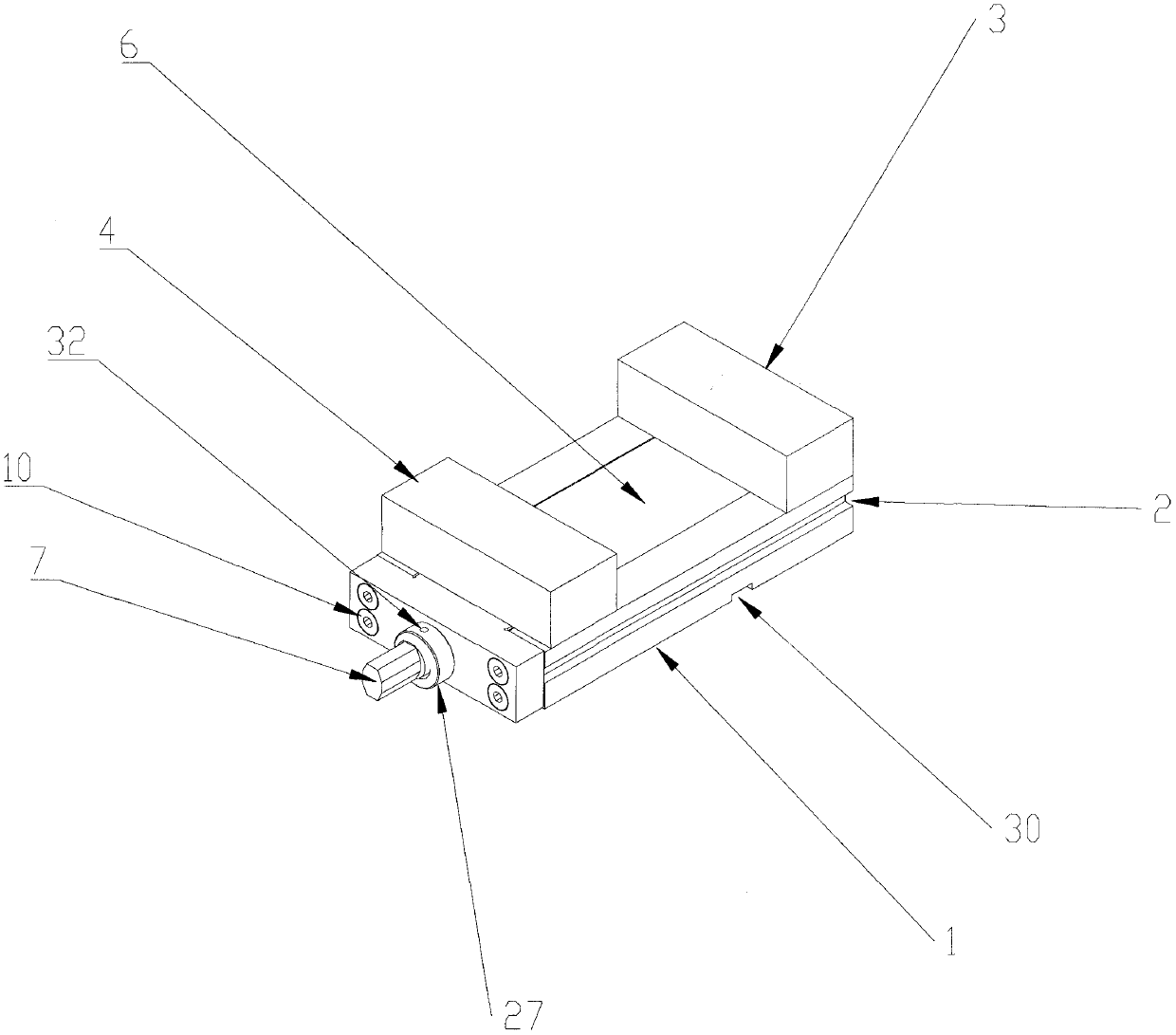

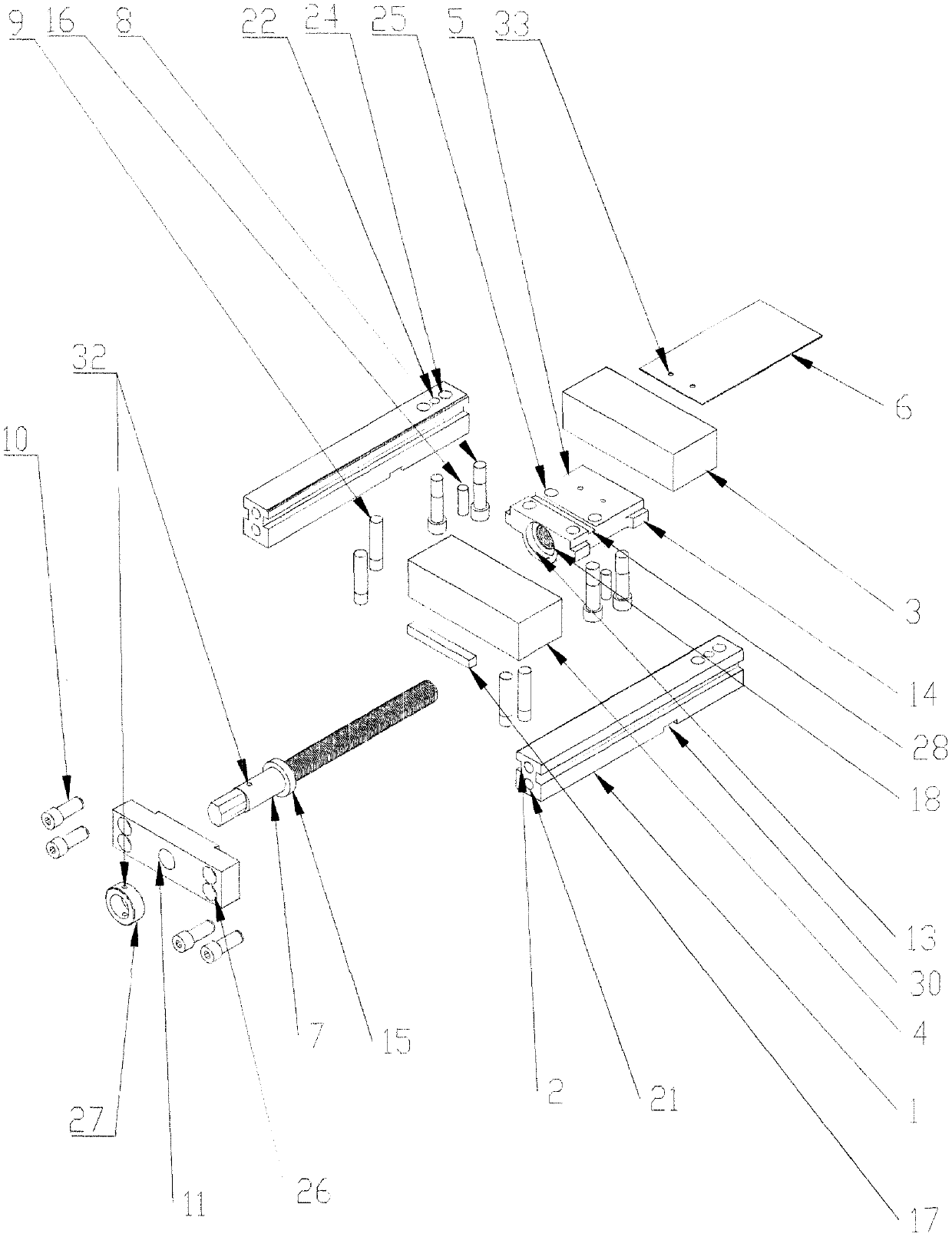

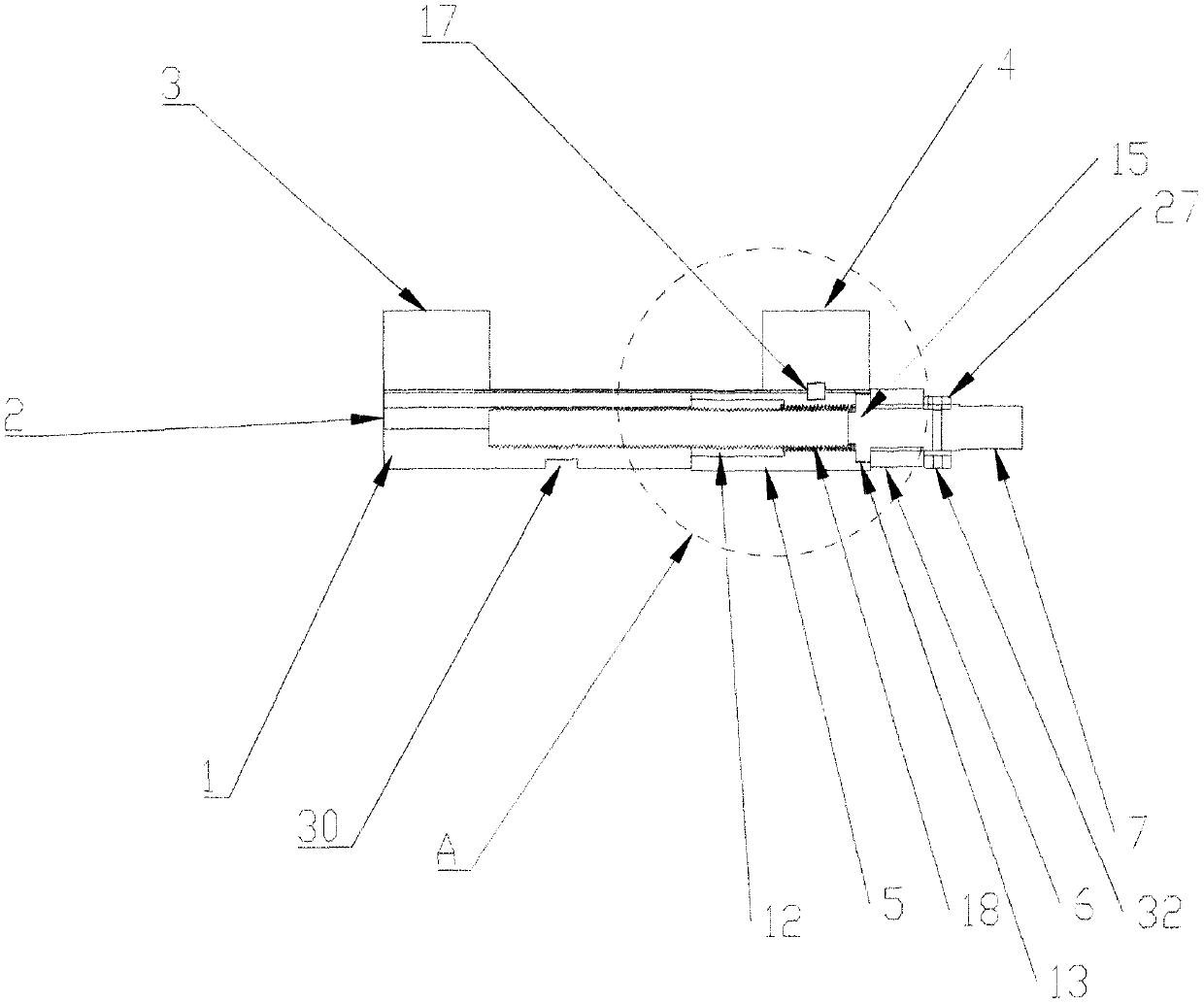

Embodiment 1

[0067] by Figure 1 to Figure 16 As shown in the overall three-dimensional view, internal cross-sectional view, individual component three-dimensional view, internal cross-sectional view and partial enlarged view of the present invention, a modular steel combined machine flat-nose pliers includes two elongated sleeper rails 1, the sleeper rail The cross section of 1 is an irregular I-shaped. The two sleeper rails 1 are installed horizontally at a certain distance between them. The first gap 2 in the middle part of the side is kept horizontal and corresponding. The two sleeper rails are provided with a second There are two gaps 30 (used to fix the sleeper rail 1 on the processing table), the top of the front ends of the two sleeper rails 1 is provided with a fixed jaw 3 fixedly connected; each sleeper rail 1 is connected to the fixed jaw The two first fixing holes 24 of the sleeper rail 1 penetrate from bottom to top (the number of the first fixing holes 24 is at least one, of co...

Embodiment 2

[0078] by Figure 17 to Figure 21 Another improved embodiment of the present invention is shown. On the basis of Example 1, the second notch 30 at the bottom is subtracted from the two sleeper rails 1, and a fixedly connected rotating chassis 36 is added at the bottom to rotate The main body of the chassis 36 is provided with an external hole 40 for connecting external equipment and or rotating parts; the place where the rotating chassis 36 intersects the two sleeper rails is provided with a bottom-up fourth fixing hole 39, in order to facilitate the two sleeper rails 1 to realize the positioning function, the middle of the two fourth fixing holes 39 is provided with a non-through third pin hole 37 (the first pin hole 22 and the second pin hole 23 in embodiment 1 can be eliminated or retained (Also) In this embodiment, the positions of the bottoms of the two sleeper rails 1 corresponding to the fourth fixing holes 39 and the first pin holes 37 of the rotating chassis 36 are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com