Metal oil filling pipe for assembling plastic oil pipe head

A fuel oil pipe and oil pipe head technology, which is applied in the field of auto parts, can solve the problems of large human error, low standardization, and low elongation, and achieve the effect of reducing metal welding steps, no human error, and reducing overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

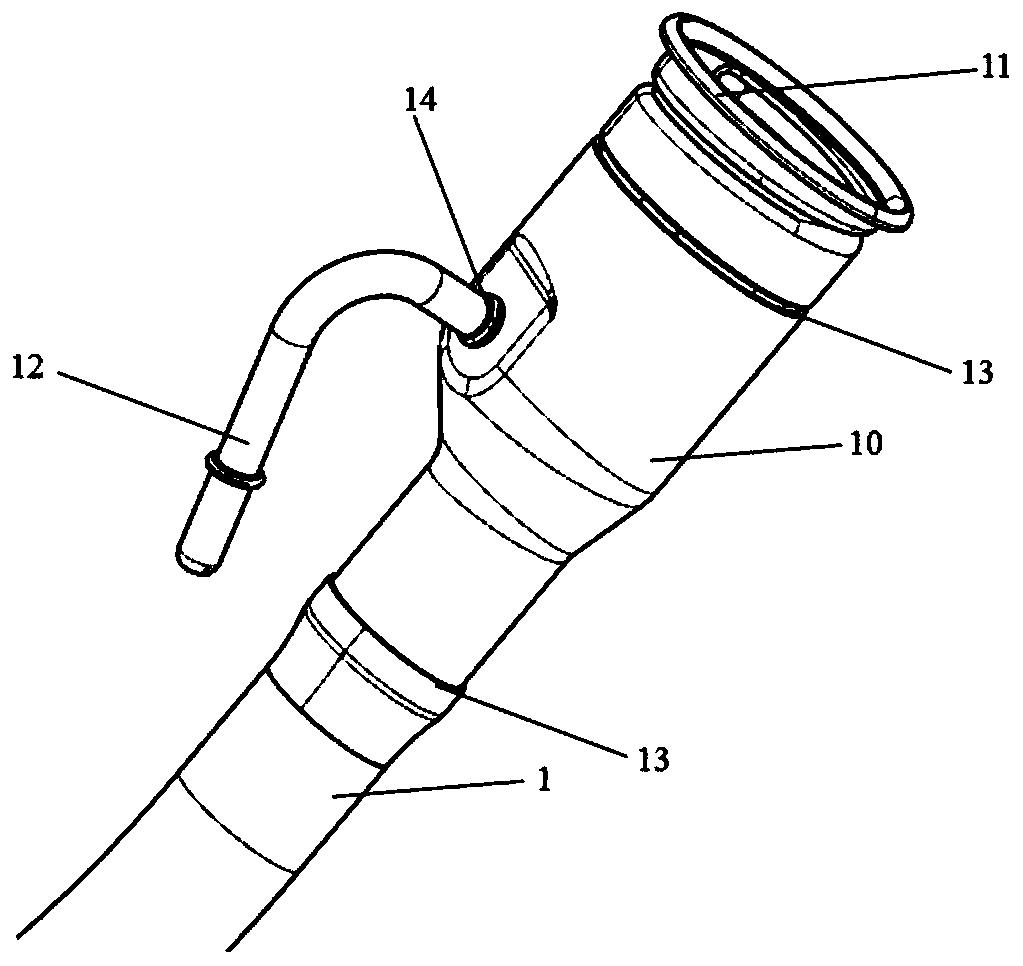

[0028] Such as Figure 2-3 with Figure 6-8 As shown, a metal filling pipe assembled with a plastic oil pipe head includes a main pipe 1 of a metal filling pipe and a part 2 of a plastic oil pipe head. The plastic oil pipe head part 2 is adapted to the main pipe 1 of a metal filling pipe. Together and between the two are sealed and connected by a seal 3, and one side of the plastic oil pipe head part 2 is assembled to connect to the air return pipe 4, and the function of the air return pipe 4 is to circulate fuel vapor during the refueling process of the car.

[0029] The plastic oil pipe head part 2 includes an upper section, a middle section and a lower section. The upper section and the lower section are respectively in a cylindrical structure and the two are connected together through the middle section. 2. The lower section is assembled at the first assembly place 7 with the main pipe 1 of the oil filling pipe through threaded connection, buckle, etc., and is detachably ...

Embodiment 2

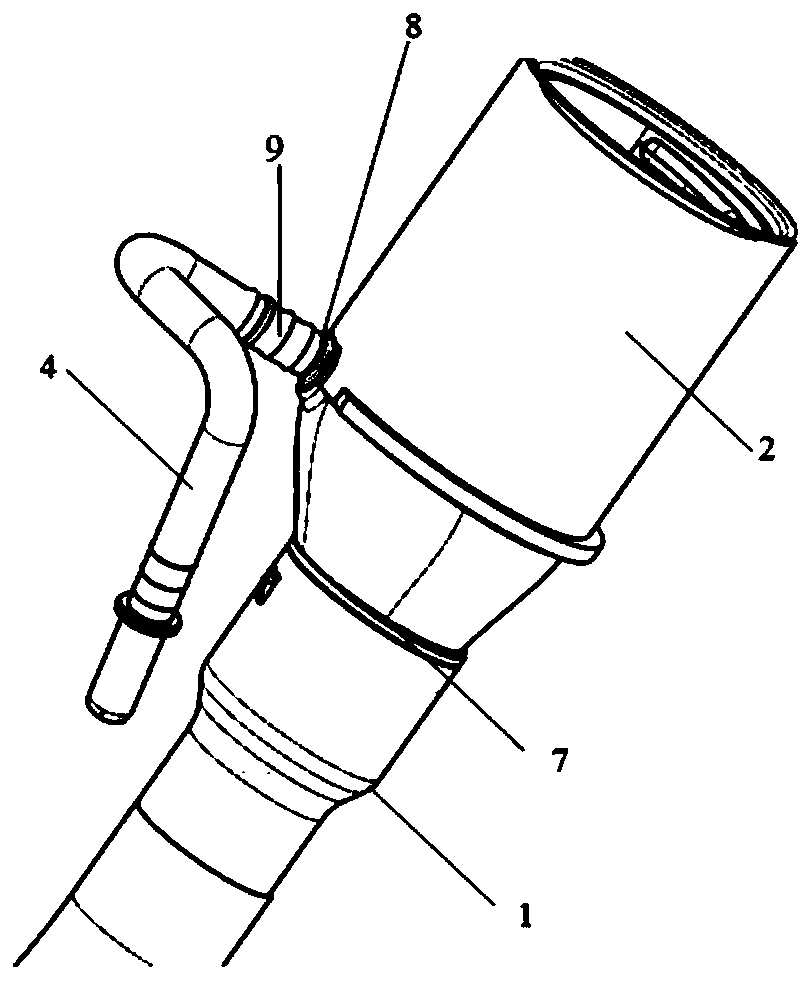

[0034] Such as figure 2 , Figure 4 with Figure 6-8 As shown, a metal oil filling pipe assembled with a plastic oil pipe head includes a metal oil pipe head main body 1 and a plastic oil pipe head part 2. The plastic oil pipe head part 2 is adapted to the metal oil pipe main body 1, and the two are connected in an assembled manner. Together and between the two are sealed and connected by a seal 3, and one side of the plastic oil pipe head part 2 is assembled to connect the return air pipe 4, and the function of the air return pipe 4 is to circulate fuel vapor during the refueling process of the car.

[0035]The plastic oil pipe head part 2 includes an upper section, a middle section and a lower section. The upper section and the lower section are respectively in a cylindrical structure and the two are connected together through the middle section. 2. The lower section, at the first assembly point 7, is assembled with the main pipe 1 of the oil filling pipe through threaded...

Embodiment 3

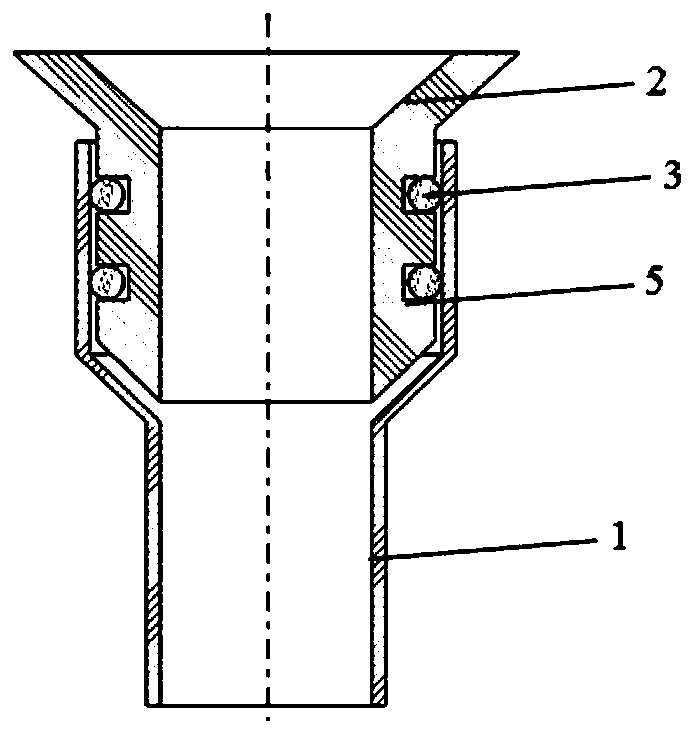

[0039] Such as figure 2 with Figure 5-8 As shown, a metal oil filling pipe assembled with a plastic oil pipe head includes a metal oil pipe head main body 1 and a plastic oil pipe head part 2. The plastic oil pipe head part 2 is adapted to the metal oil pipe main body 1, and the two are connected in an assembled manner. Together and between the two are sealed and connected by a seal 3, and one side of the plastic oil pipe head part 2 is assembled to connect to the air return pipe 4, and the function of the air return pipe 4 is to circulate fuel vapor during the refueling process of the car.

[0040] The plastic oil pipe head part 2 includes an upper section, a middle section and a lower section. The upper section and the lower section are respectively in a cylindrical structure and the two are connected together through the middle section. 2. The lower section, at the first assembly point 7, is assembled with the fuel pipe main pipe 1 through threaded connection, buckle, et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com