Double roller omni-directional power caster and omni-directional mobile platform of mobile robot

A technology of mobile robots and double rollers, which is applied in the direction of power devices, electric power devices, motor vehicles, etc., and can solve problems such as complex sealing design, limited flexibility of mobile platforms, size and weight restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

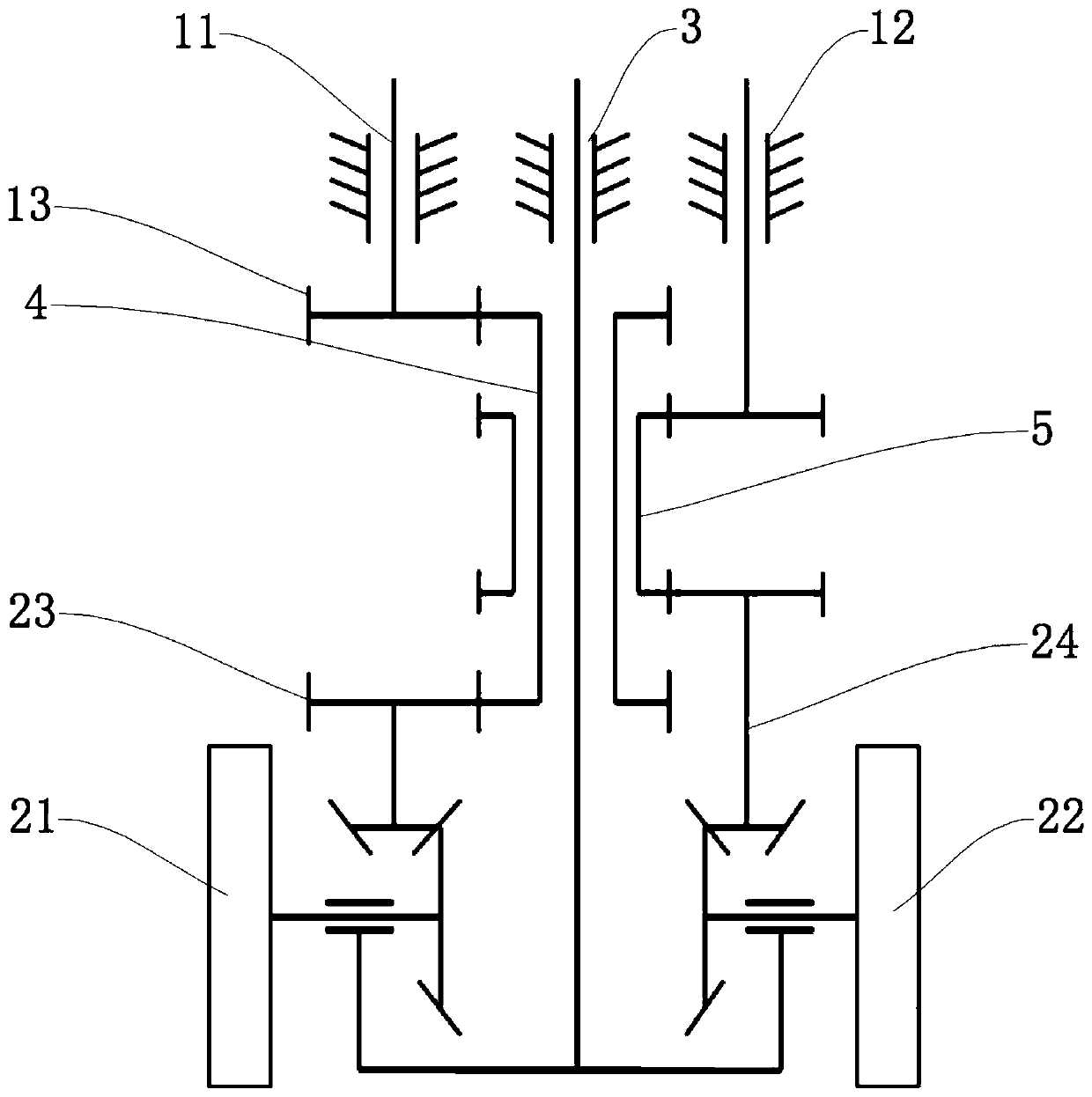

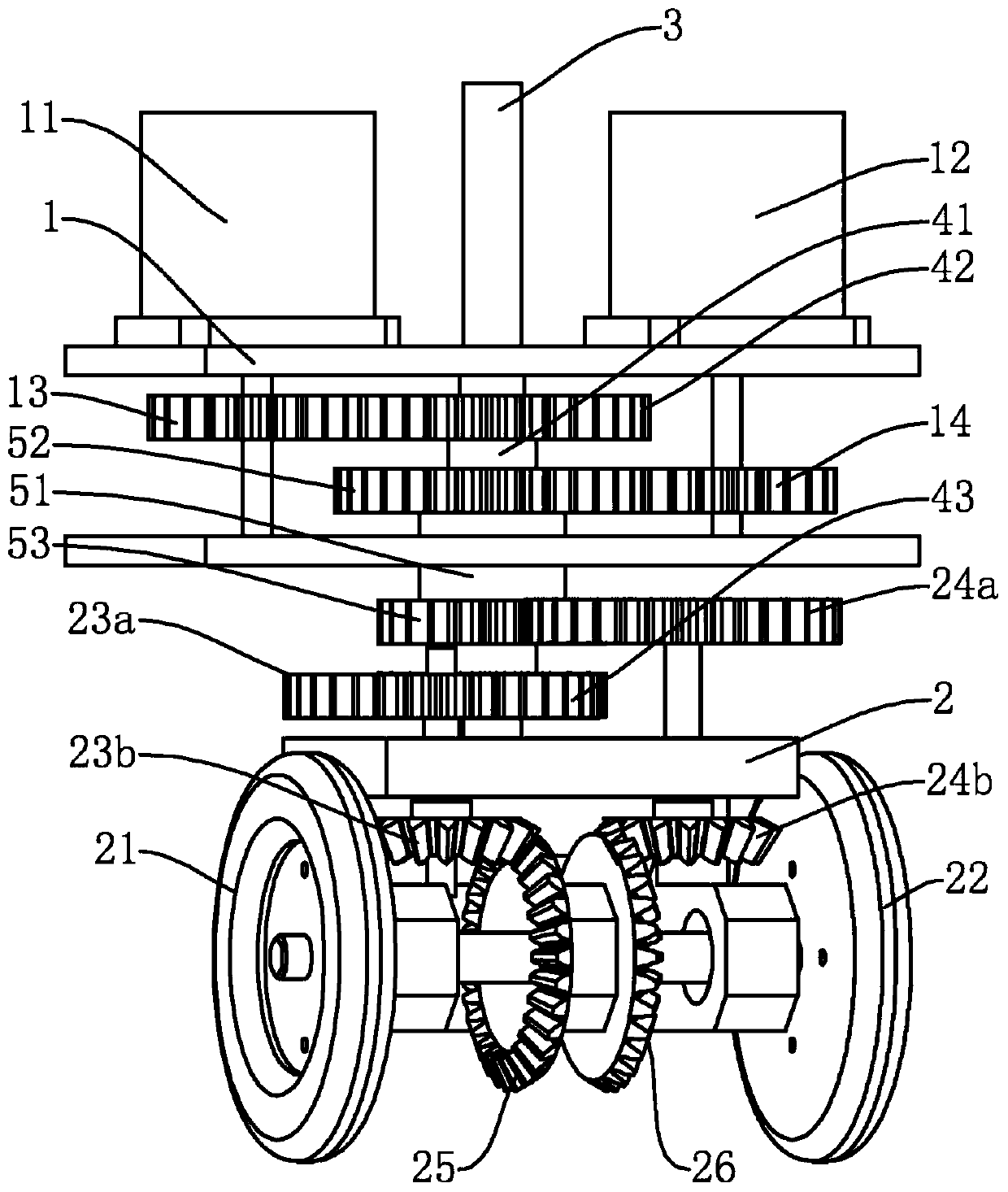

[0037] Such as Figure 1 to Figure 4 As shown, the dual-roller omnidirectional power caster of this embodiment includes a frame 1 with a vertically arranged and rotatable steering shaft 3 mounted on the frame 1 and a wheel frame 2 mounted on the lower end of the steering shaft 3. The wheel carrier 2 is provided with a first roller 21 and a second roller 22 which are arranged side by side and can rotate independently. The rotation axis of the first roller 21 and the rotation axis of the second roller 22 coincide.

[0038] The frame 1 is provided with a first driving motor 11 and a second driving motor 12 arranged side by side and working independently. The first driving motor 11 and the second driving motor 12 are installed in the frame 1, and even if the wheel frame 2 turns endlessly, there is no problem of cable entanglement. The first driving motor 11 and the second driving motor 12 respectively drive the corresponding first roller 21 and the second roller 22 to rotate through...

Embodiment 2

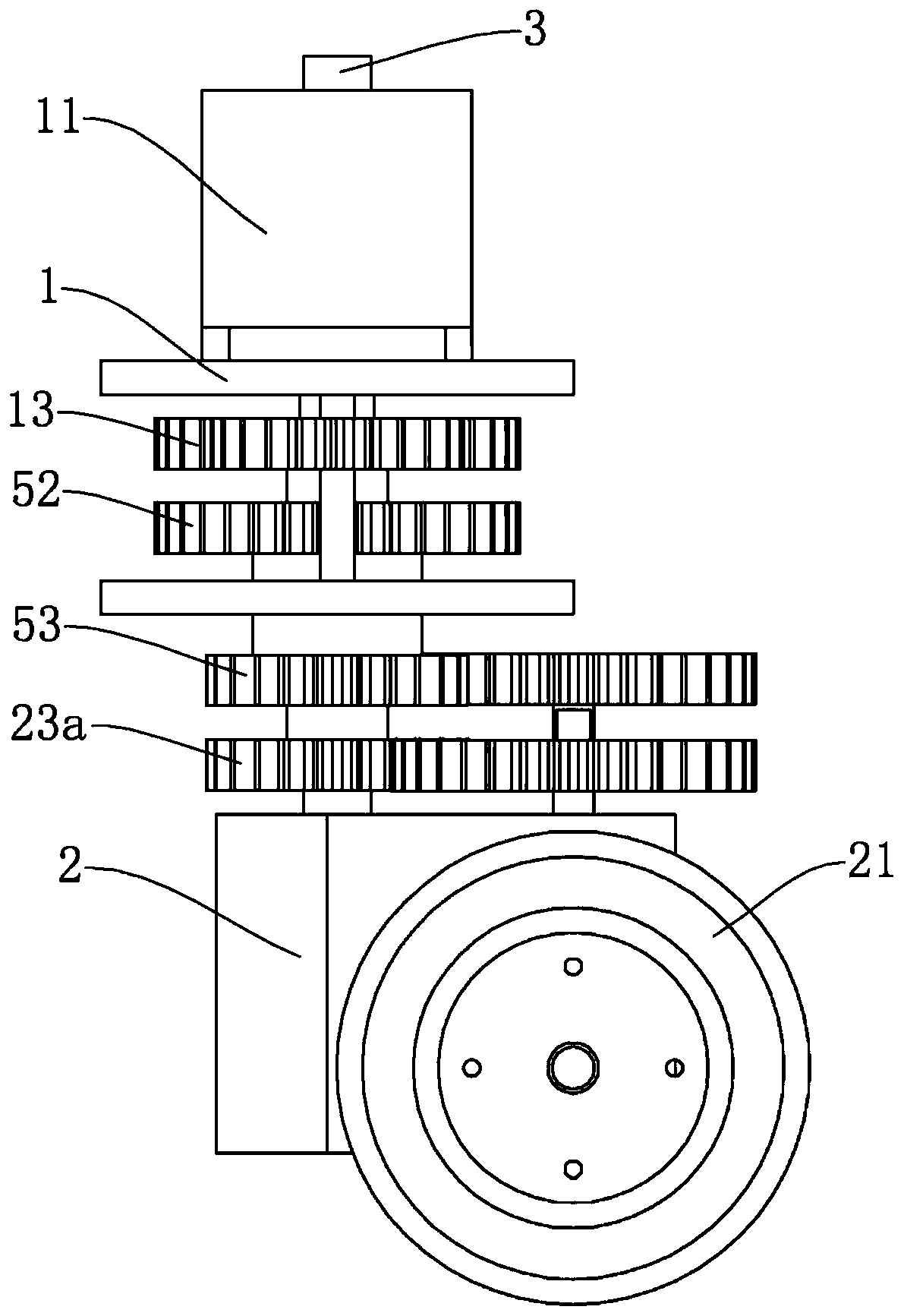

[0058] Such as Figure 7 with Figure 8 As shown, the dual-roller omnidirectional power caster of this embodiment includes a frame 1 with a vertically arranged and rotatable steering shaft 3 mounted on the frame 1 and a wheel frame 2 mounted on the lower end of the steering shaft 3. The wheel carrier 2 is provided with a first roller 21 and a second roller 22 which are arranged side by side and can rotate independently. The rotation axis of the first roller 21 and the rotation axis of the second roller 22 coincide.

[0059] The difference between this embodiment and the first embodiment is that the first output gear portion 43 and the second output gear portion 53 are respectively bevel transmission gears. The wheel carrier 2 is provided with a third transmission gear 23 and a fourth transmission gear 24. The third transmission gear 23 is composed of a third bevel gear portion 23c meshing with the first output gear portion 43 and a third spur gear portion 23d for driving the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com