A method for improving the mechanical properties of liquid crystal polymer products

A technology of liquid crystal polymers and mechanical properties, applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of excessive cooling, uneven heating, etc., and achieve the effects of improving toughness, weakening internal stress, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

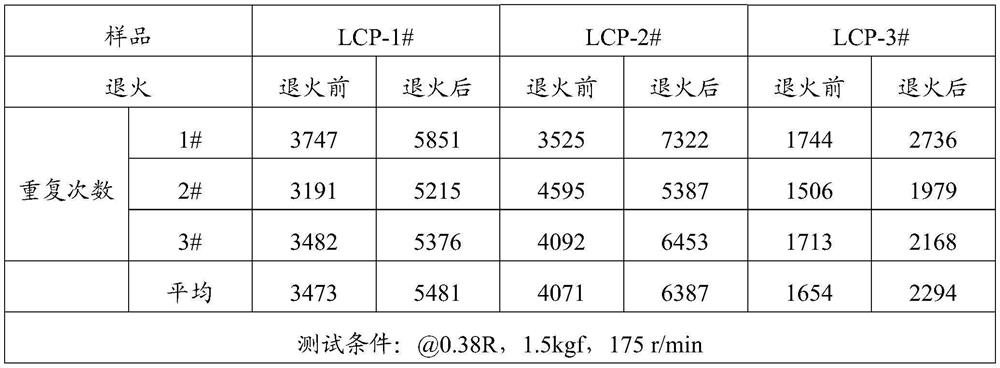

Examples

Embodiment 1

[0038] The method for improving the mechanical properties of liquid crystal polymer products, the specific steps are:

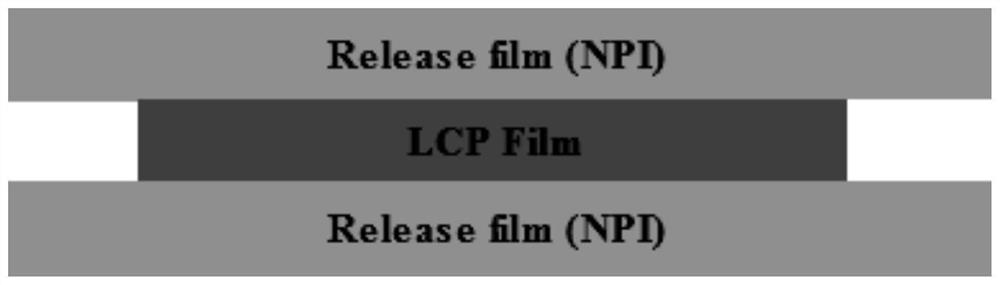

[0039] 1) Add protective films on the upper and lower sides of the liquid crystal polymer film - thermosetting polyimide film (see figure 1 ), the area of the thermosetting polyimide film is greater than the area of the liquid crystal polymer film, and the edge of the thermosetting polyimide film is applied with a tiny weight;

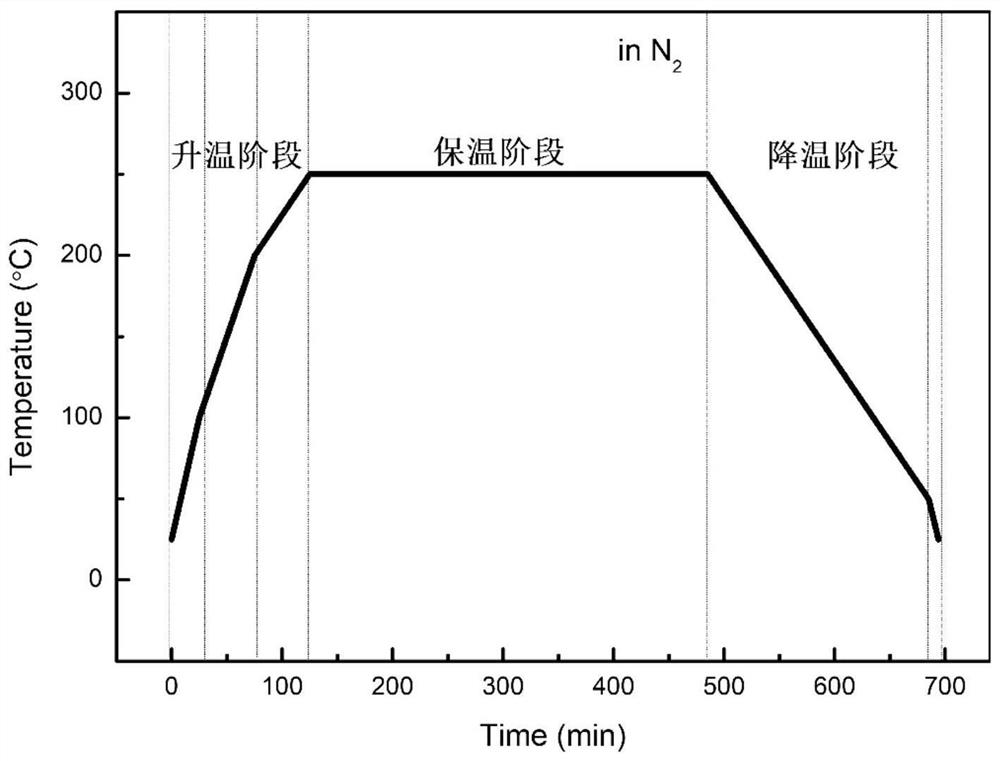

[0040] 2) Put the liquid crystal polymer film covered with a protective film into a vacuum drying oven for heat treatment under a nitrogen atmosphere. Before heating up, vacuumize the vacuum oven, inject nitrogen, vacuumize, and inject nitrogen, repeat 5 times , until the residual air in the vacuum drying oven is replaced by a nitrogen atmosphere, and the oven is completely filled with a nitrogen atmosphere; then start to heat up for heat treatment (see figure 2 ), the heat treatment temperature is 250°C, and the time is 6h;

...

Embodiment 2

[0044]The method for improving the mechanical properties of liquid crystal polymer products, the specific steps are:

[0045] 1) Add a protective film—a thermosetting polyimide film on the upper and lower sides of the liquid crystal polymer film, the area of the thermosetting polyimide film is greater than the area of the liquid crystal polymer film, and the thermosetting polyimide film A tiny weight is applied to the edge of the imide film;

[0046] 2) Put the liquid crystal polymer film covered with a protective film into a vacuum drying oven for heat treatment under a nitrogen atmosphere. Before heating up, vacuumize the vacuum oven, inject nitrogen, vacuumize, and inject nitrogen, repeat 5 times , until the residual air in the vacuum drying oven is replaced by a nitrogen atmosphere, and the oven is completely filled with a nitrogen atmosphere; then start to heat up for heat treatment, the temperature of the heat treatment is 250 ° C, and the time is 6 hours;

[0047] ...

Embodiment 3

[0050] The method for improving the mechanical properties of liquid crystal polymer products, the specific steps are:

[0051] 1) Add a protective film—a thermosetting polyimide film on the upper and lower sides of the liquid crystal polymer film, the area of the thermosetting polyimide film is greater than the area of the liquid crystal polymer film, and the thermosetting polyimide film A tiny weight is applied to the edge of the imide film;

[0052] 2) Put the liquid crystal polymer film covered with a protective film into a vacuum drying oven for heat treatment under a nitrogen atmosphere. Before heating up, vacuumize the vacuum oven, inject nitrogen, vacuumize, and inject nitrogen, repeat 5 times , until the residual air in the vacuum drying oven is replaced by a nitrogen atmosphere, and the oven is completely filled with a nitrogen atmosphere; then start to heat up for heat treatment, the temperature of the heat treatment is 250 ° C, and the time is 6 hours;

[0053]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com