Method for recovering crude oil by cleaning oil sludge sand

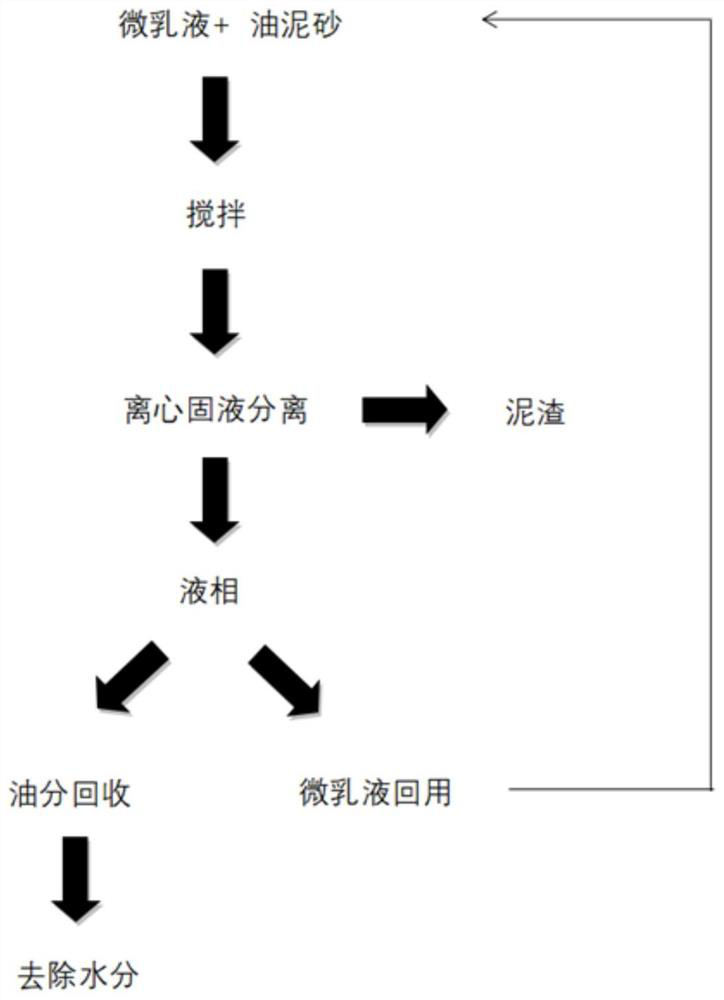

A technology for cleaning oil and oil sludge, which is applied in chemical instruments and methods, the petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problems of high cost and non-reusable compound preparations, and achieve efficient recovery, cost saving, and high deoiling efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Mix sodium dodecylbenzene sulfonate (SDBS) / kerosene / n-butanol / sodium chloride / water to obtain oil-in-water winsor type I microemulsion; kerosene 100mL, water 100mL, sodium chloride 0.7g, n-butyl Alcohol 10mL and SDBS 4g;

[0070] The microemulsion prepared in the step (1) is mixed with the Gudao No. 1 oil sludge sand of drying according to the ratio of 10ml: 1g in a container, and the container is sealed;

[0071] Stir the mixture in step (2), the stirring speed is 1000r / min, the temperature is 50°C, and the stirring time is 3h, so that the microemulsion and the oil sludge sand are fully contacted;

[0072] The mixture stirred in step (3) is centrifuged for solid-liquid separation, the centrifugation speed is 4000r / min, the centrifugation time is 10min, after centrifugation, the upper liquid phase is poured out; the liquid phase is a mixture of microemulsion and oil;

[0073] Put the liquid phase poured out in step (4) to stand and separate, so that the oil is at the t...

Embodiment 2

[0080] Mix sodium dodecylbenzenesulfonate (SDBS) / kerosene / n-butanol / sodium chloride / water to obtain oil-in-water winsor type I microemulsion; 100mL of kerosene, 100mL of water, 0.8g of sodium chloride, and Butanol 9mL and SDBS 4g;

[0081] The microemulsion prepared in the step (1) is mixed with the dried oily sludge sand according to the ratio of 10ml: 1g in the container, and the container is sealed;

[0082] Stir the mixture in step (2), the stirring speed is 1000r / min, the temperature is 50°C, and the stirring time is 3h, so that the microemulsion and the oil sludge sand are fully contacted;

[0083] The mixture stirred in step (3) is centrifuged for solid-liquid separation, the centrifugation speed is 4000r / min, the centrifugation time is 10min, after centrifugation, the upper liquid phase is poured out; the liquid phase is a mixture of microemulsion and oil;

[0084] Put the liquid phase poured out in step (4) to stand and separate, so that the oil is at the top, and th...

Embodiment 3

[0091] Mix sodium dodecylbenzene sulfonate (SDBS) / kerosene / n-butanol / sodium chloride / water to obtain oil-in-water winsor type I microemulsion; kerosene 100mL, water 100mL, sodium chloride 0.9g, n-butyl Alcohol 12mL and SDBS 4.5g;

[0092] The microemulsion prepared in the step (1) is mixed in the container according to the ratio of 10ml: 1g with the dried Gudong No. 2 oily sand, and the container is sealed;

[0093] Stir the mixture in step (2), the stirring speed is 1000r / min, the temperature is 50°C, and the stirring time is 3h, so that the microemulsion and the oil sludge sand are fully contacted;

[0094] The mixture stirred in step (3) is centrifuged for solid-liquid separation, the centrifugation speed is 4000r / min, the centrifugation time is 10min, after centrifugation, the upper liquid phase is poured out; the liquid phase is a mixture of microemulsion and oil;

[0095] Put the liquid phase poured out in step (4) to stand and separate, so that the oil is at the top, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com