Movable uncoiling speed reducer for nonferrous metal working industry

A non-ferrous metal and gold processing technology, applied in transmission boxes, mechanical equipment, transmission parts, etc., can solve the problems of affecting the uncoiling quality, low uncoiling power, low uncoiling efficiency, etc., to take into account the overall structure of the reducer. Power limitation, taking into account the effect of unwinding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Further description will be made below in conjunction with the accompanying drawings.

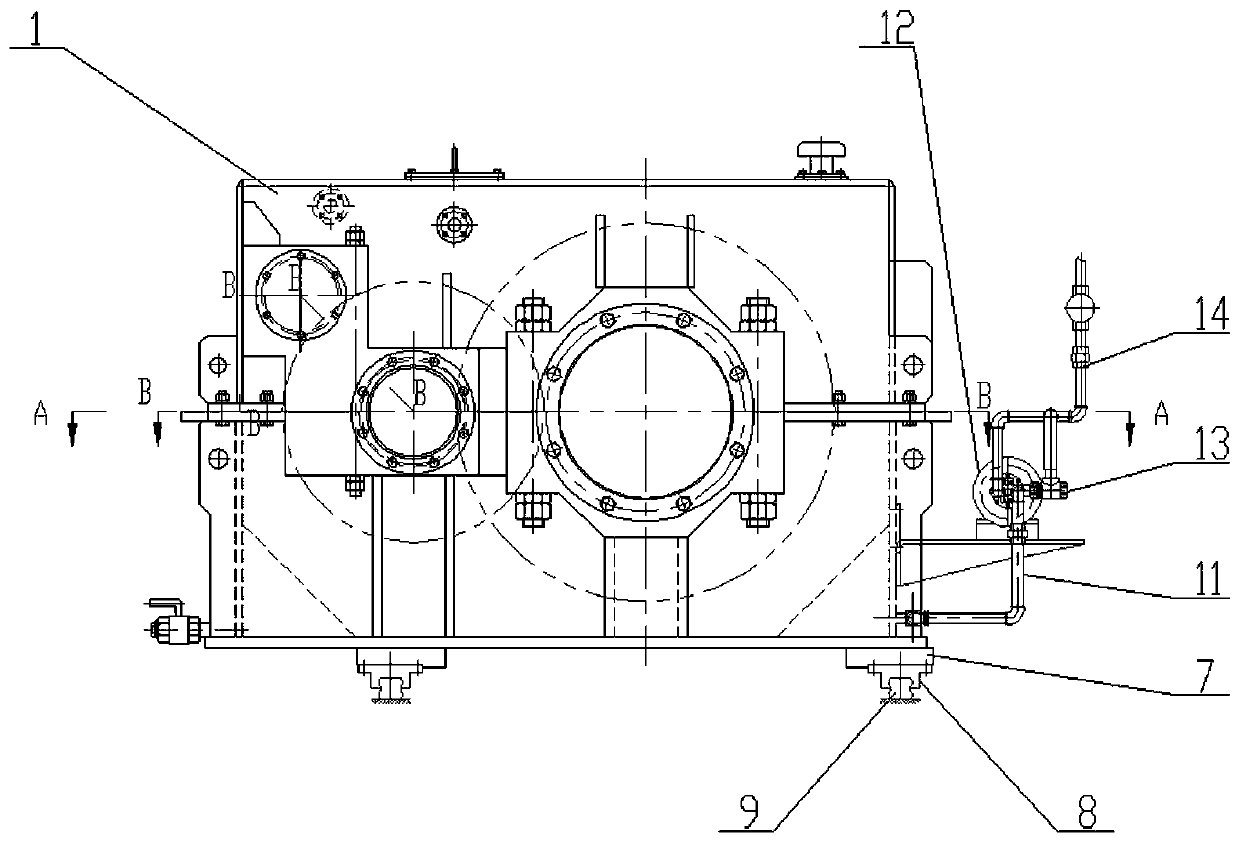

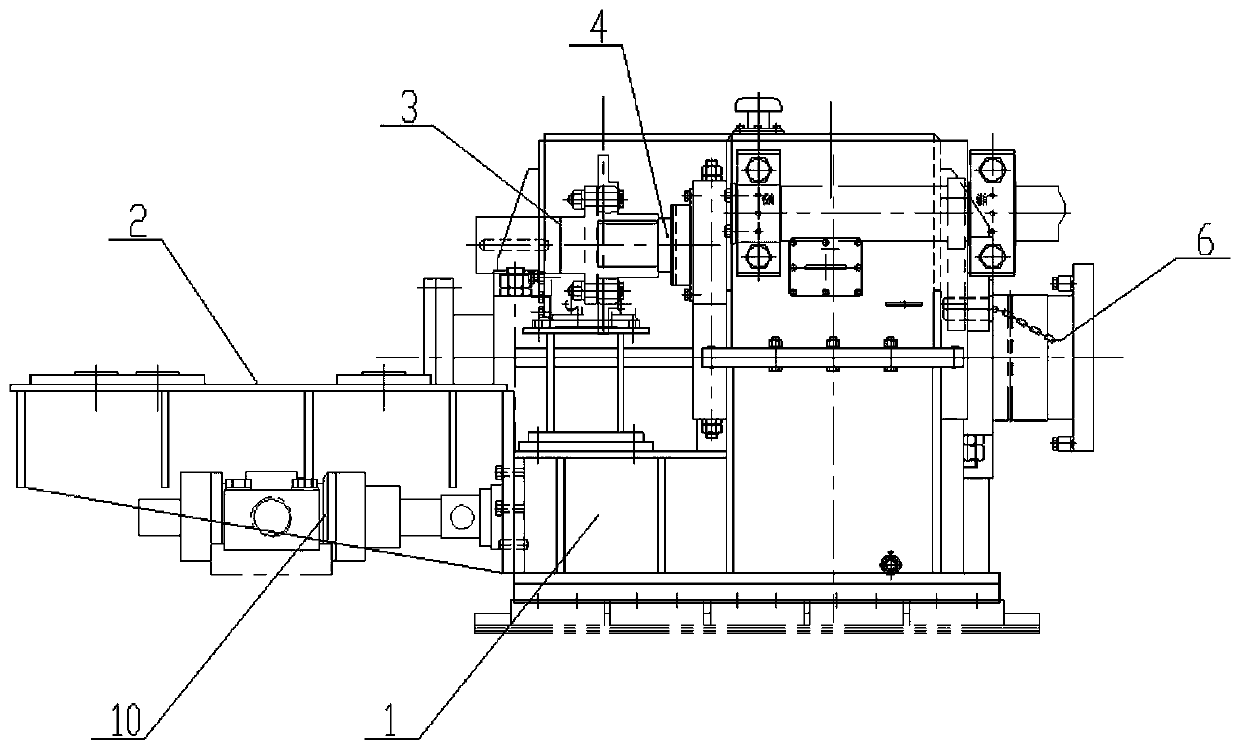

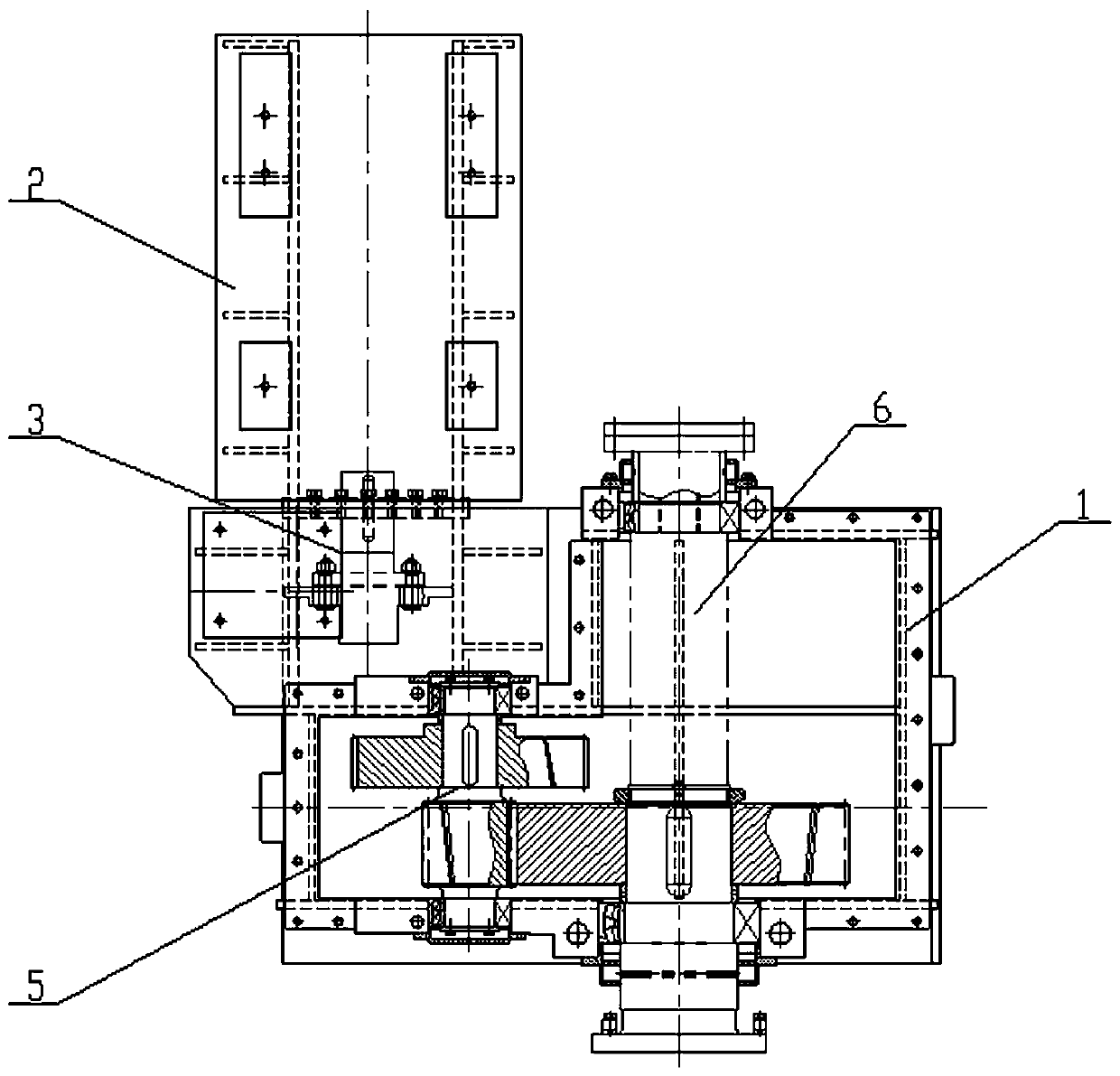

[0013] Figure 1-4 As shown, a movable decoiling reducer for the non-ferrous metal gold processing industry includes a box body 1, a motor bracket 2, a coupling 3, an input shaft 4, a multi-stage cylindrical gear transmission mechanism 5, an output shaft 6, and a foot seat 7 , Slide rail seat 8, track 9, hydraulic push rod cylinder 10, lubricating pipeline 11, oil pump 12, safety valve 13, lubricating piping 14. The input shaft 4 extends from the rear side of the box body 1, and the motor bracket 2 corresponding to the lower part of the output shaft is connected to the rear side of the box body 1. The motor bracket 2 is installed with the motor connected to the input shaft 4 through the coupling 3, and the front side of the output shaft 6 Stretch out the box corresponding to the uncoiling station, the left and right bases 7 of the box body 1 are connected with the slide rail seat 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com