High-efficiency and safe dryer

A dryer and safe technology, applied in drying solid materials, drying gas layout, non-progressive dryers, etc., can solve the problems of low drying efficiency, dangerous closed containers, uneven moisture removal, etc., to improve drying efficiency , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

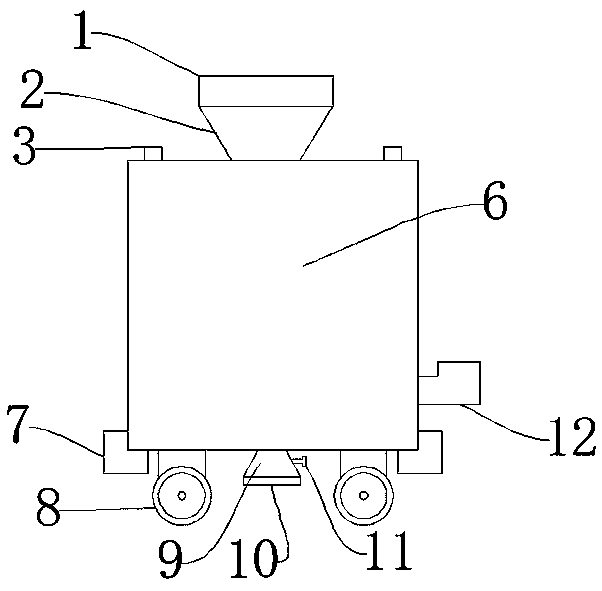

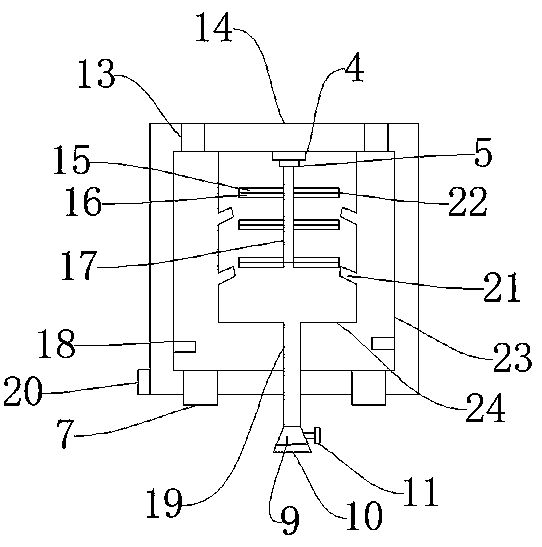

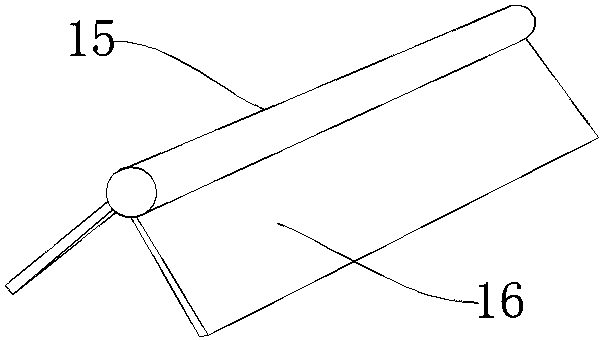

[0033] like Figure 1-Figure 4 As shown, an efficient and safe dryer includes a feed funnel 2, a motor 4, a drying barrel 6, a heating pipe 18, and a discharge funnel 9. The upper end of the feed funnel 2 is provided with a large sealing cover 1, a large sealing cover 1 It is used to seal the feeding funnel 2. The lower end of the feeding funnel 2 is provided with a drying barrel 6. The drying barrel 6 is used for drying seeds. The drying barrel 6 is provided with a hole plug 3. One side of the drying barrel 6 is provided with a drying Box 12, the lower end of the drying barrel 6 is provided with a blower 7, the blower 7 is used to blow air from the bottom, the side of the blower 7 is provided with a universal wheel 8, the universal wheel 8 is used to support the whole device, and the drying barrel 6 is formed by the outer barrel Body 14, inner barrel body 23, air outlet 13, mixer 24, heating pipe 18, and hot air pipe 21. Outer barrel 14 is provided with air outlet 13. Air out...

Embodiment 2

[0035] The difference between this embodiment and embodiment 1 is:

[0036] The feed funnel 2 and the large sealing cover 1 are connected by a hinge, and the feed funnel 2 and the drying barrel 6 are connected by welding. The hinge connection is helpful for the opening and closing and installation of the large sealing cover 1, and the welding makes the feed funnel 2 and the drying barrel Barrel 6 is more closely connected.

[0037] Working principle: The seeds to be dried are put into the drying barrel 6 from the feeding funnel 2, and then enter the mixer 24. The blower 7 blows air from the bottom, and the blown air is heated by the heating tube 18 to become hot air rising, and the hot air flows from the inner barrel The side wall of the body 23 passes through to heat up the inner barrel body 23. Finally, the hot air enters the mixer 24 from the inner barrel body 23 through the hot air pipe 21 to dry the seeds. 22 rotates, the scraper 16 can stir the seeds in the mixer 24 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com