Method and device for measuring impurity-containing specific gravity of grains harvested by combine harvester

A technology that combines harvesters and measurement methods, which is applied to computer components, instruments, character and pattern recognition, etc., to achieve the effect of satisfying real-time performance, small data volume, storage capacity, data transmission rate and bandwidth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

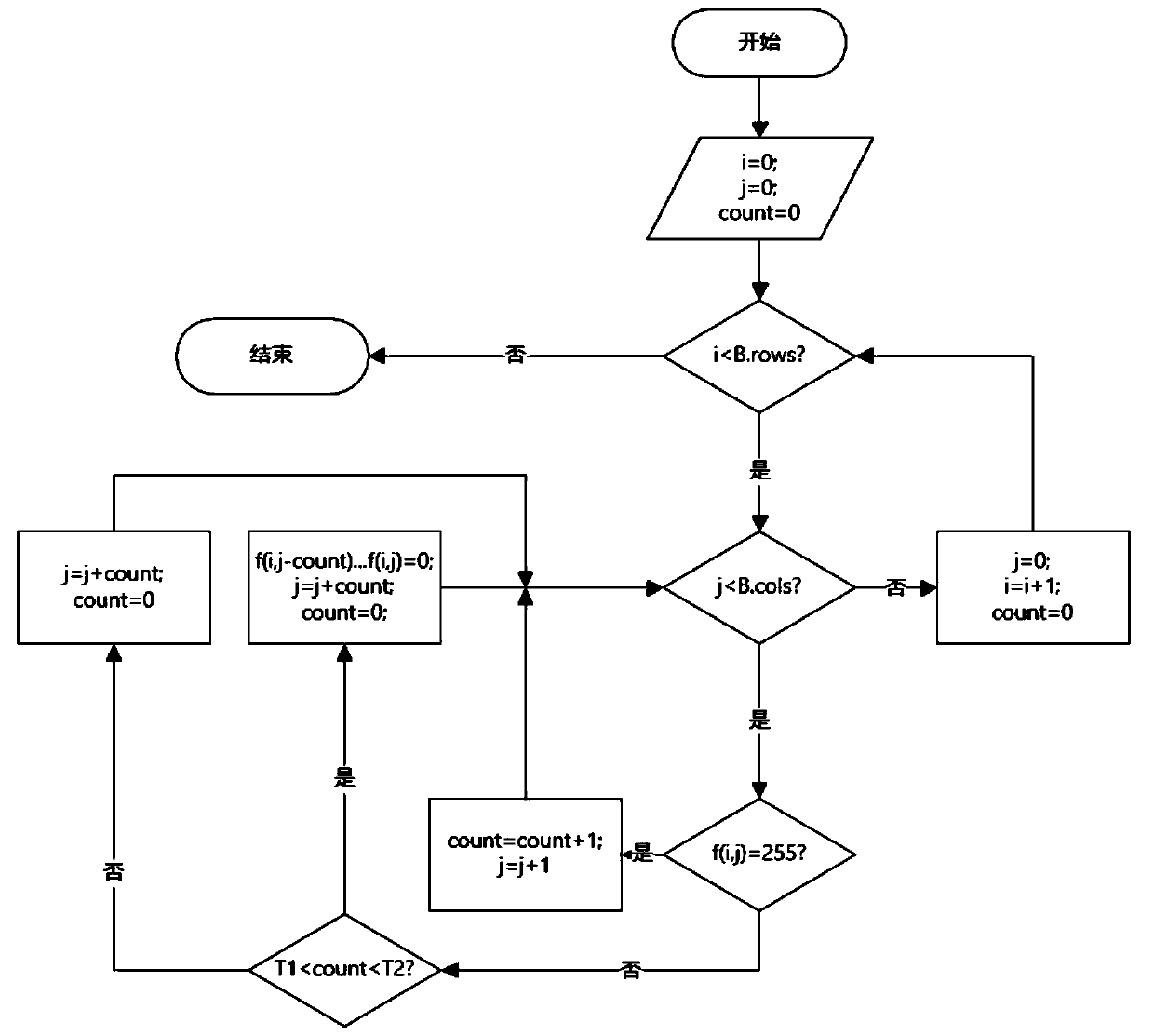

[0040] According to the deficiencies in the current research, the present invention discloses a method based on image processing for real-time detection of the proportion of impurities contained in the harvest of a combine harvester and the required device. The method can better guide the combine harvester online in real time. Work, improve harvest quality.

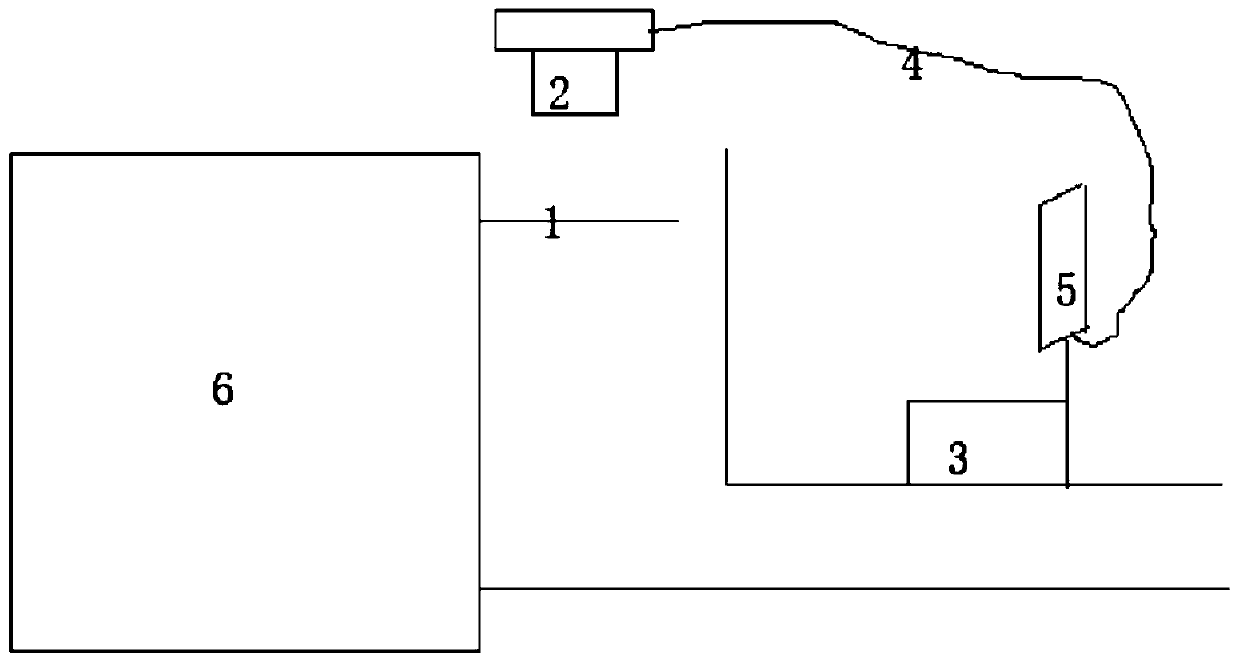

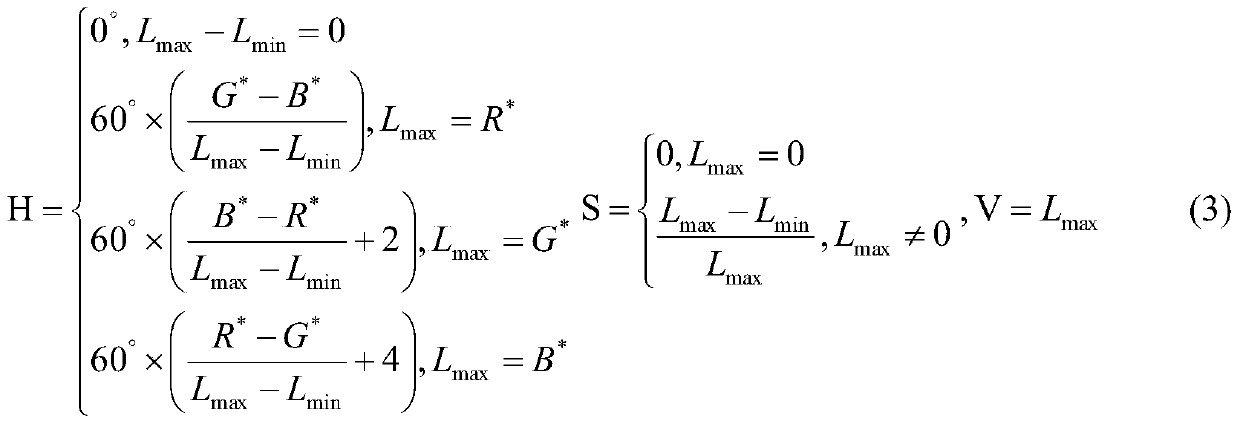

[0041] The invention proposes a measuring device for measuring the proportion of impurities contained in grains harvested by a combine harvester, including industrial cameras, lighting equipment, shock absorption equipment and image processing devices. The industrial cameras are used to collect images of harvested grains, and the lighting equipment is used to collect images for the industrial cameras. The light source is provided at any time, and the shock absorption equipment is used to eliminate the interference caused by the vibration during the operation of the combine harvester on the images collected by the industria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com