Separator assembly and battery module

A technology for isolation boards and components, which is applied to battery pack parts, secondary batteries, circuits, etc., and can solve problems such as large volume, cost reduction, and complex overall structure of isolation board components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The separator plate assembly and the battery module according to the present invention will be described in detail below with reference to the accompanying drawings.

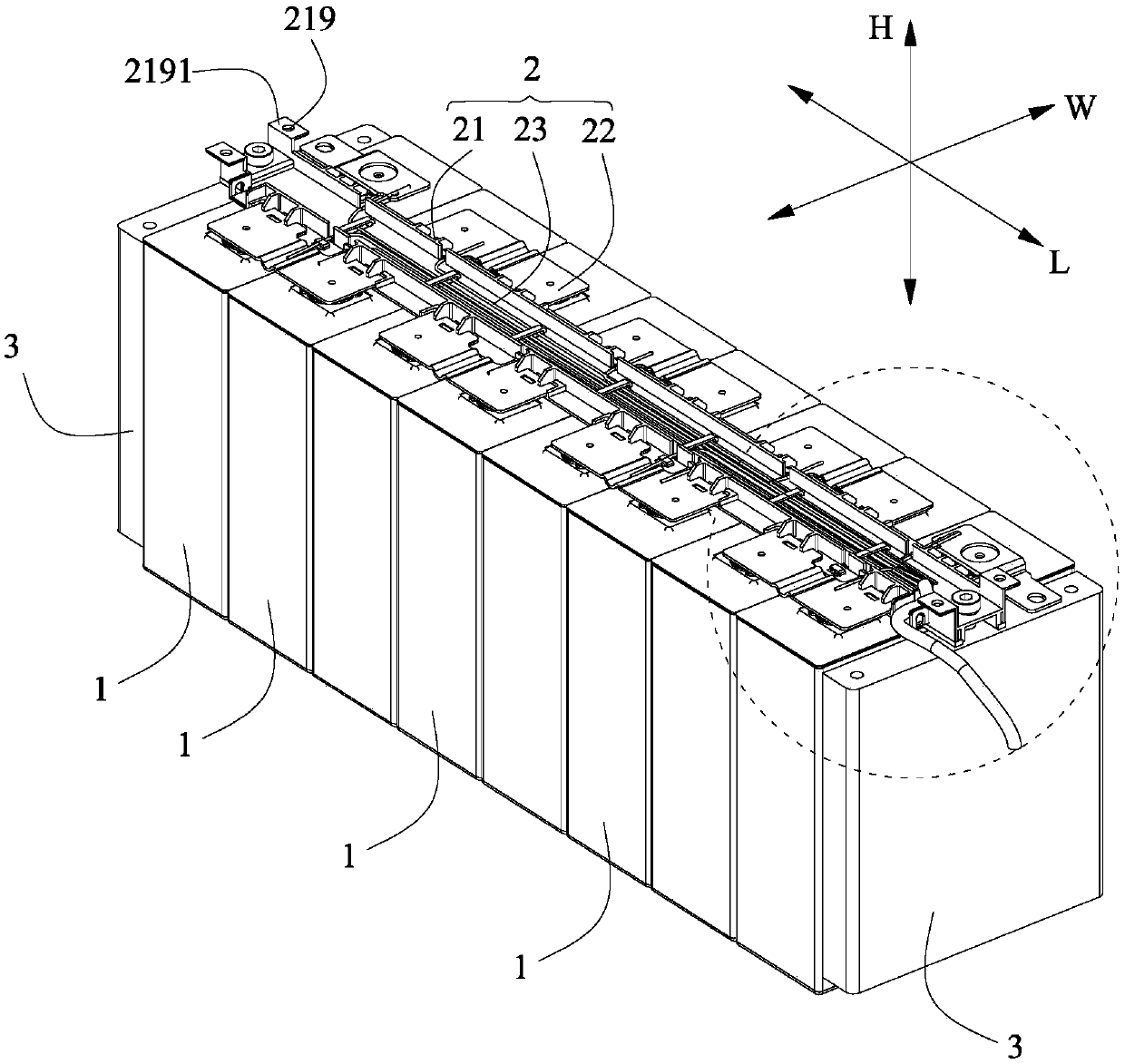

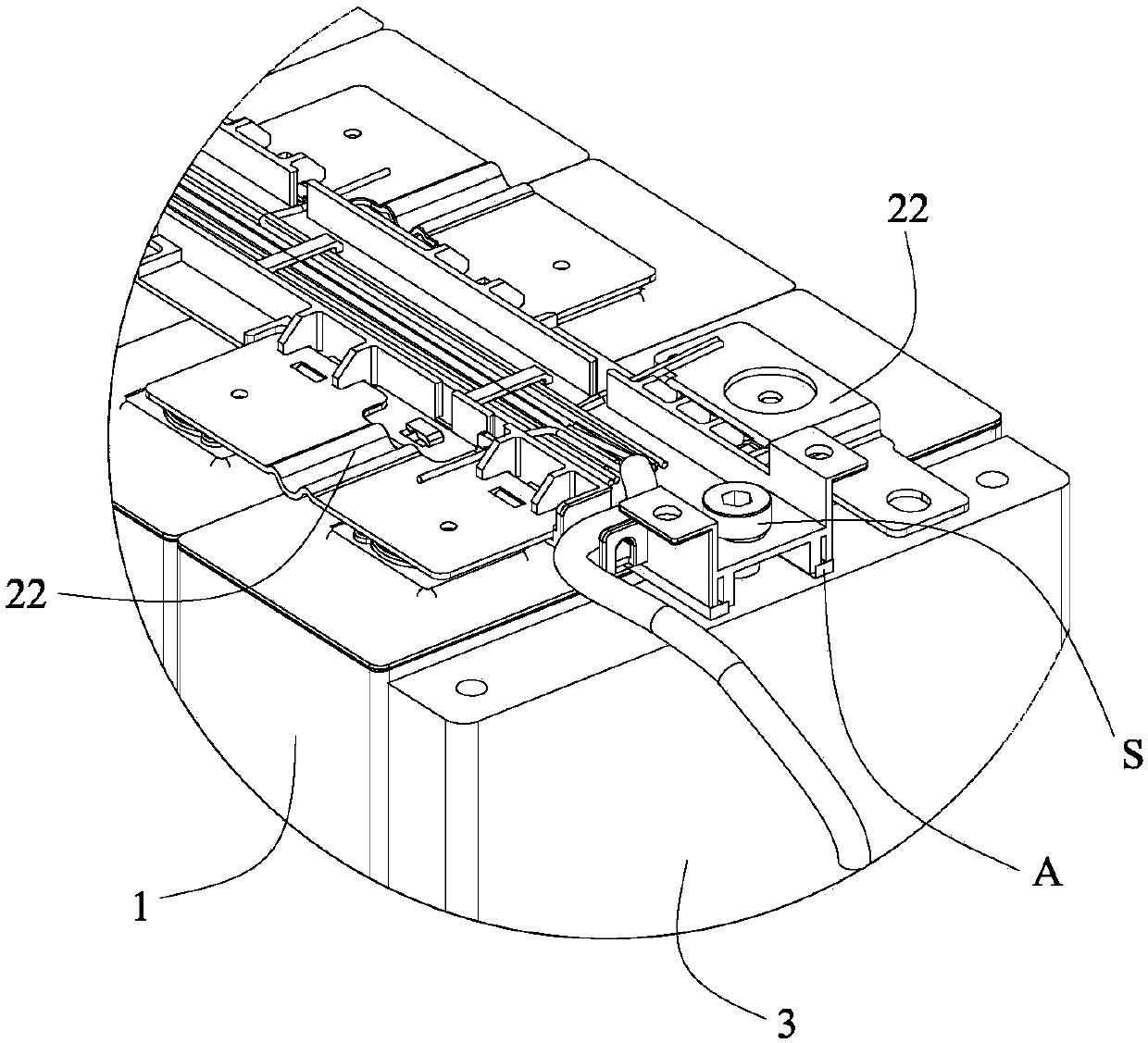

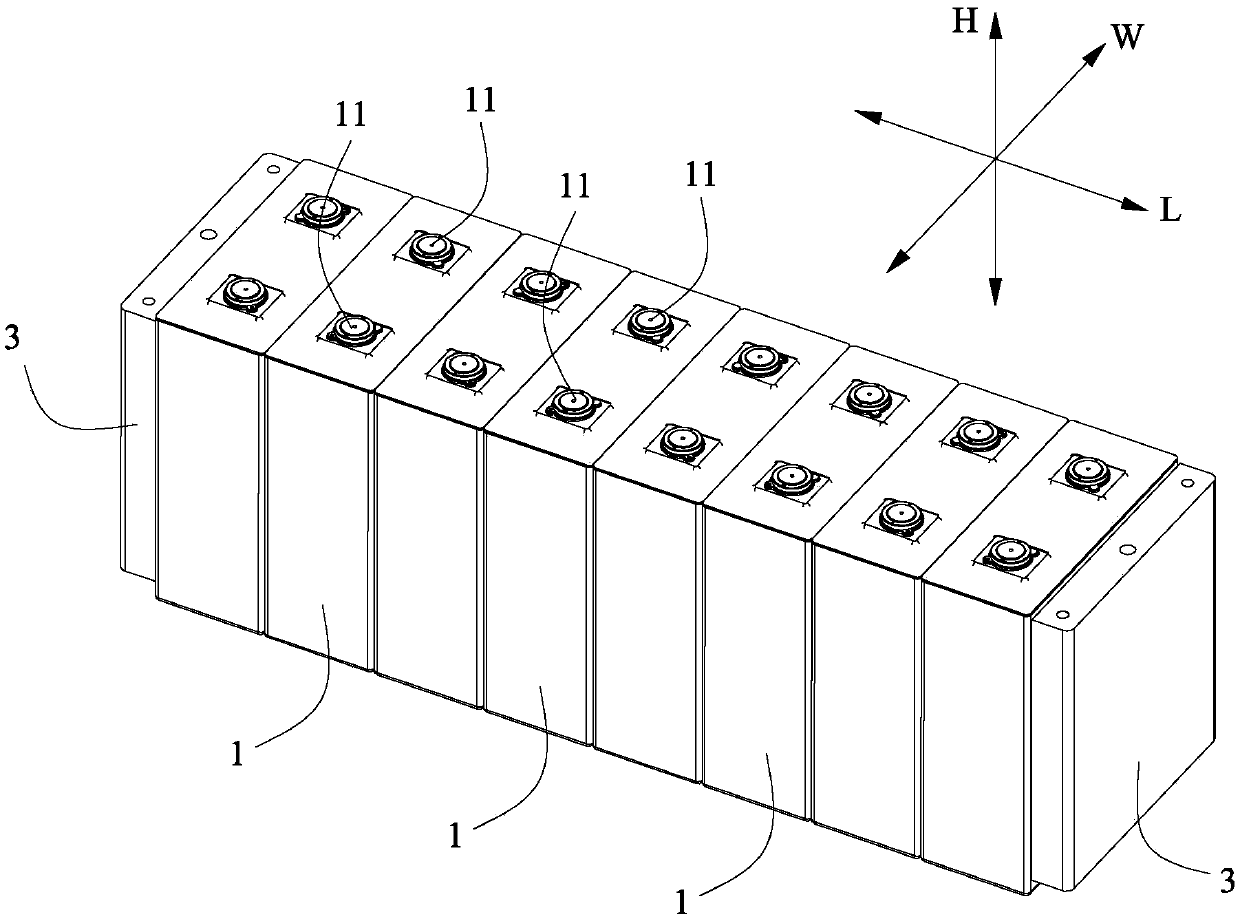

[0044] refer to Figure 1 to Figure 3 , The battery module according to the present invention includes a plurality of batteries 1, a separator assembly 2, two end plates 3 and an upper cover (not shown).

[0045] A plurality of batteries 1 are arranged side by side along the length direction L, and each battery 1 has two poles 11 arranged at intervals along the width direction W.

[0046] The two end plates 3 are respectively located at both ends of the length direction L of the plurality of batteries 1 . The two end plates 3 are used to clamp the plurality of batteries 1 in the length direction L. As shown in FIG.

[0047] refer to figure 1 , the isolation plate assembly 2 includes an isolation plate 21 , a plurality of electrical connecting pieces 22 and a plurality of sampling wire harnesses 23 . W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com