A circular waveguide tm 11 pattern exciter

A TM11, mode excitation technology, applied in the direction of waveguide devices, circuits, electrical components, etc., can solve the problems of long conversion link, difficulty in compact application, large overall error of the link, etc., and achieve small transmission loss, compact structure, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below with the accompanying drawings, the Ka-band circular waveguide TM 11 The mode exciter is taken as an example to describe the specific implementation manner of the present invention.

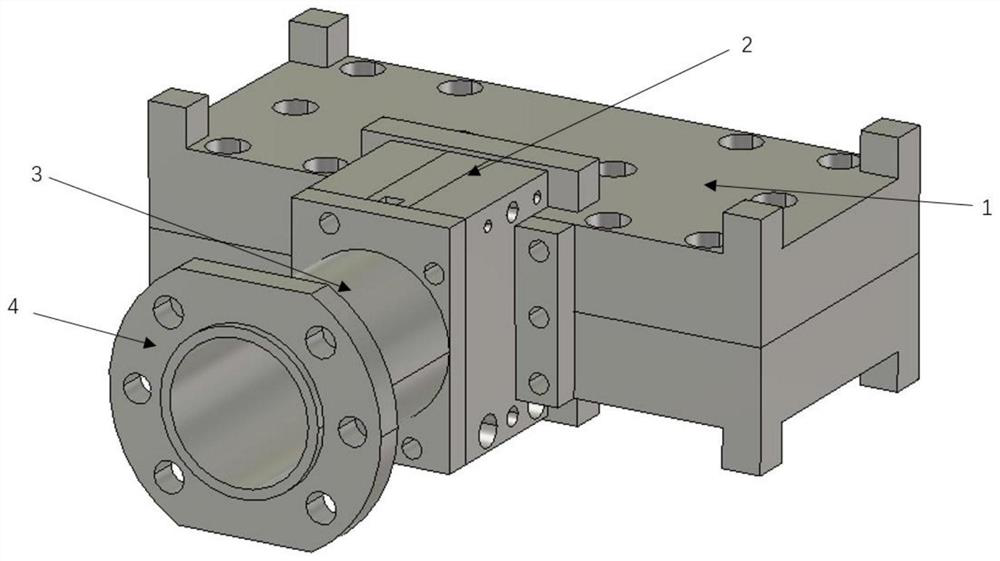

[0030] Such as figure 1 As shown, an all-metal structure Ka-band circular waveguideTM 11For the mode exciter, in order to ensure its structural strength, hard aluminum alloy is selected as its processing material. The mode exciter is composed of a power division structure 1 , a coupling excitation structure 2 and an output structure 3 , and is connected to a circular waveguide transmission link through a waveguide flange 4 .

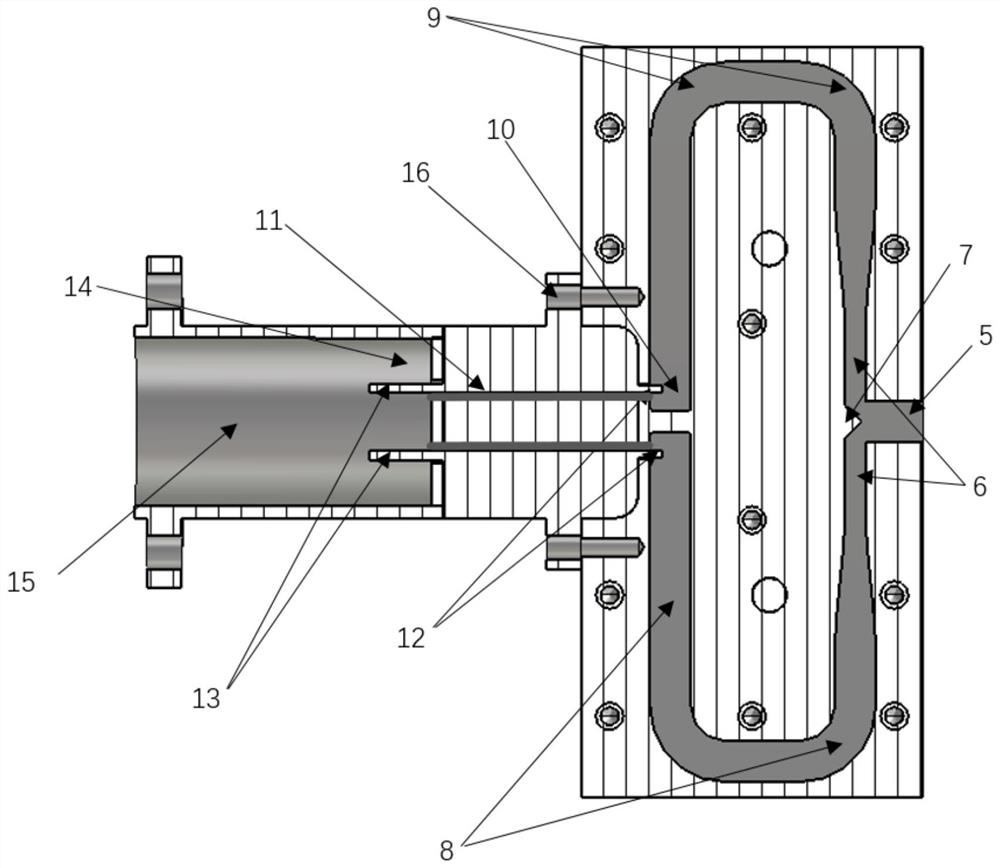

[0031] Such as figure 2 As shown, the power division structure 1 is a one-to-two power divider based on a rectangular waveguide, which is composed of a group of symmetrically arranged metal cover plates. The inner cavity between the metal covers forms a rectangular waveguide waveguide structure, including a rectangular waveguide E-plane T-junction, a gradu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com