Intermediate infrared vector vortex light generating device and method

A technology for generating device and vortex light, which is applied in optics, lasers, optical components, etc., can solve the problems of unstable transmission and low purity of vector vortex beams, achieve high mode purity, solve unstable transmission, and solve problems with low purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

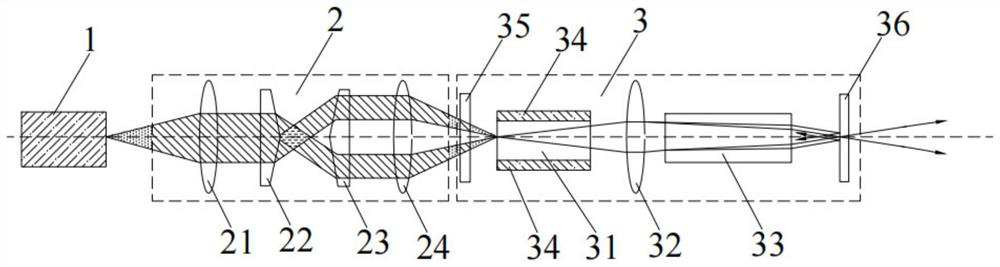

[0043] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides a mid-infrared vector vortex light generating device. The mid-infrared vector vortex light generating device includes: a pumping light source 1 for emitting a laser beam, which is arranged opposite to the pumping light source 1 and A shaping focusing structure 2 for adjusting the shape and size of the laser beam and a resonant cavity structure 3 arranged opposite to the shaping focusing structure 2 and used to generate a vector vortex beam;

[0044] The pump light source 1, the shaping focusing structure 2 and the resonant cavity structure 3 are sequentially arranged on the same optical axis, and the pumping light source 1, the shaping focusing structure 2 and the resonant cavity structure 3 are respectively Fixed connection with the base.

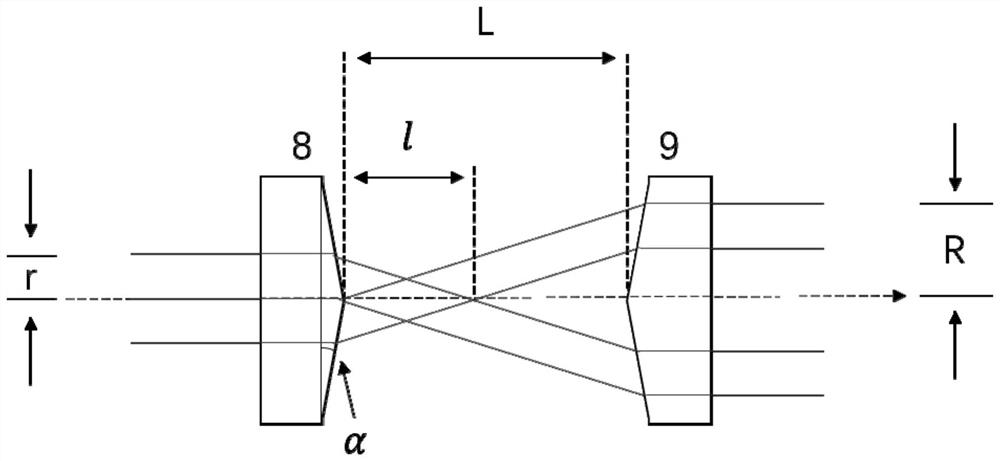

[0045]In this embodiment, the pump light source 1 can be used to provide a pump beam with a specified wavelength; the shaping focusing struc...

Embodiment 2

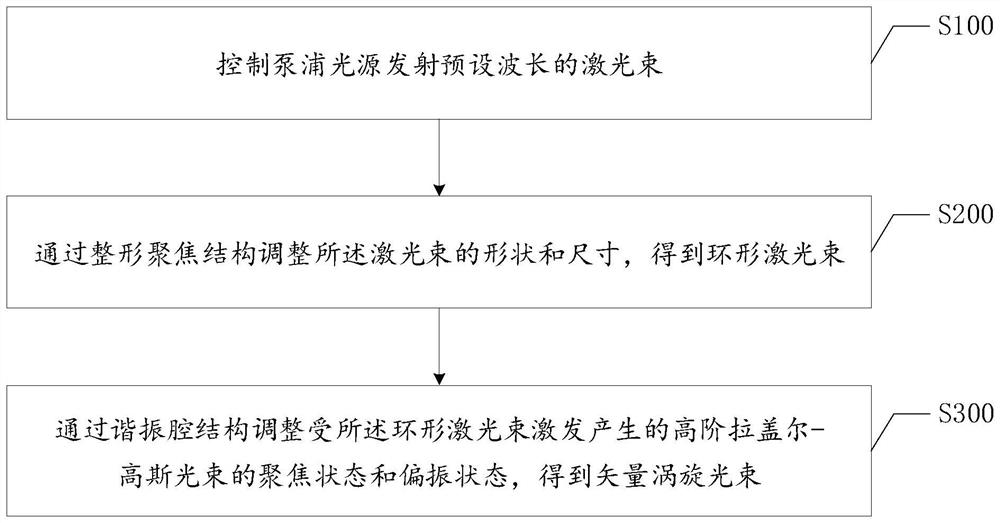

[0071] Such as image 3 As shown, the embodiment of the present invention provides a method for generating mid-infrared vector vortex light, and the method for generating mid-infrared vector vortex light includes the following steps:

[0072] Step S100, controlling the pumping light source to emit a laser beam with a preset wavelength.

[0073] In this embodiment, the method for generating mid-infrared vector vortex light is implemented based on the above-mentioned mid-infrared vector vortex light generating device; wherein, the structure of the mid-infrared vector vortex light generating device is specifically as described above.

[0074] In one implementation, the mid-infrared laser beam can be obtained by controlling the pumping light source to emit a laser beam with a preset wavelength; in this embodiment, a 976nm laser diode is used as the pumping light source to provide the pumping beam ; The pump light source can emit a pump beam with a wavelength of 976nm, so as to em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com