Hand-operated cable terminal turn-back binding device

A cable terminal and binding device technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of easy loosening of cables, slow operation speed, falling off, etc., so as not to shake or accidentally loosen, increase stability, and facilitate assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

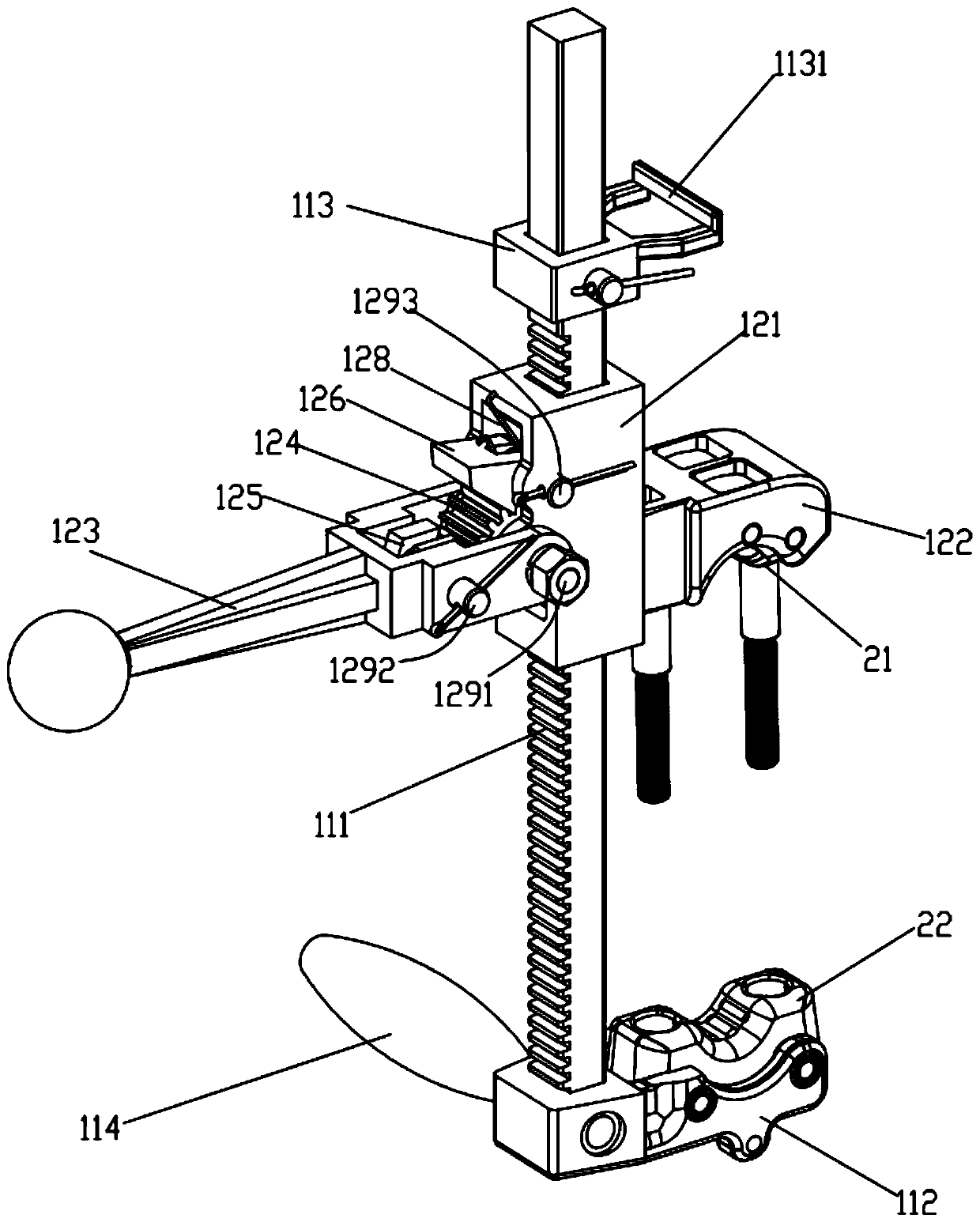

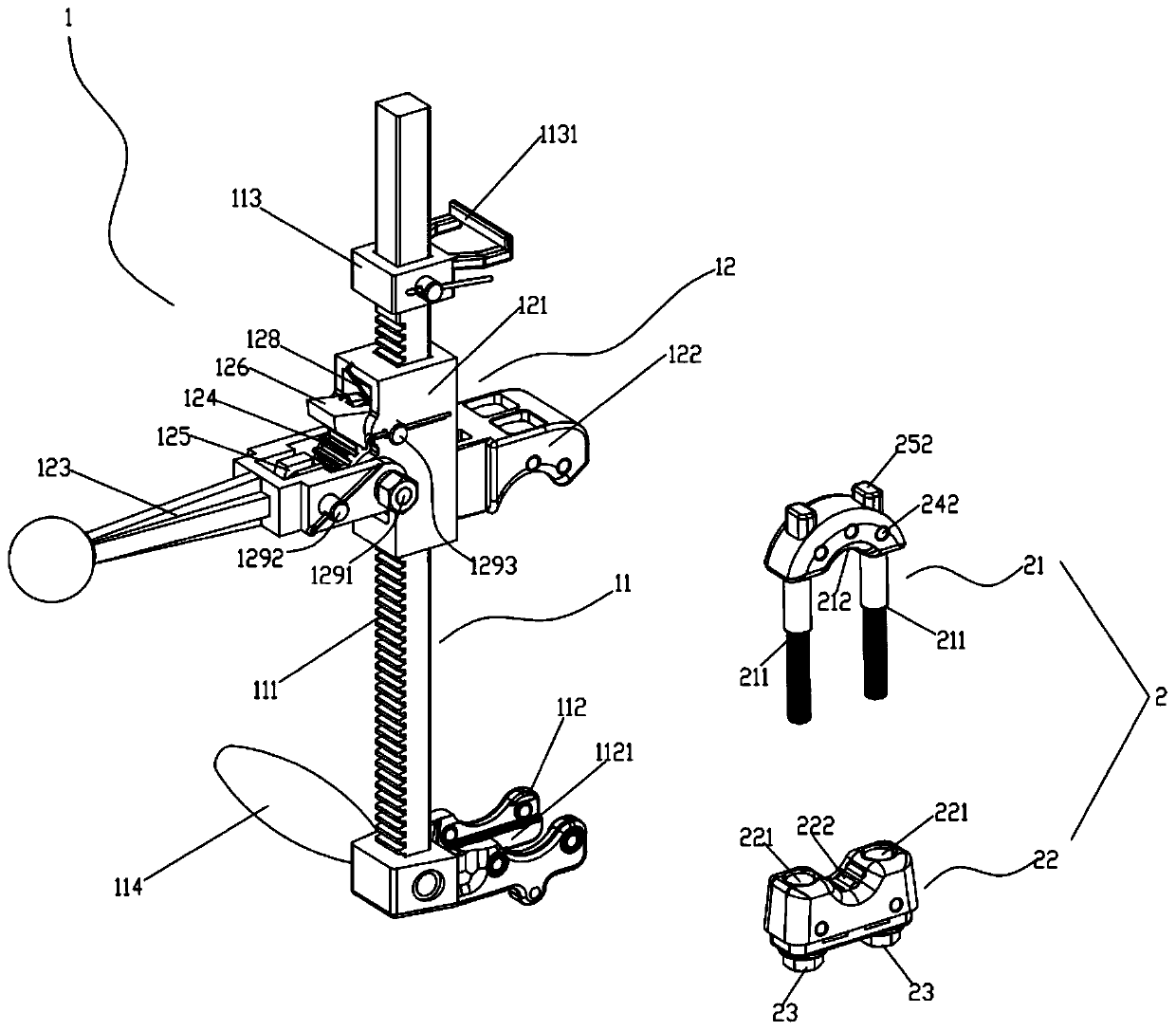

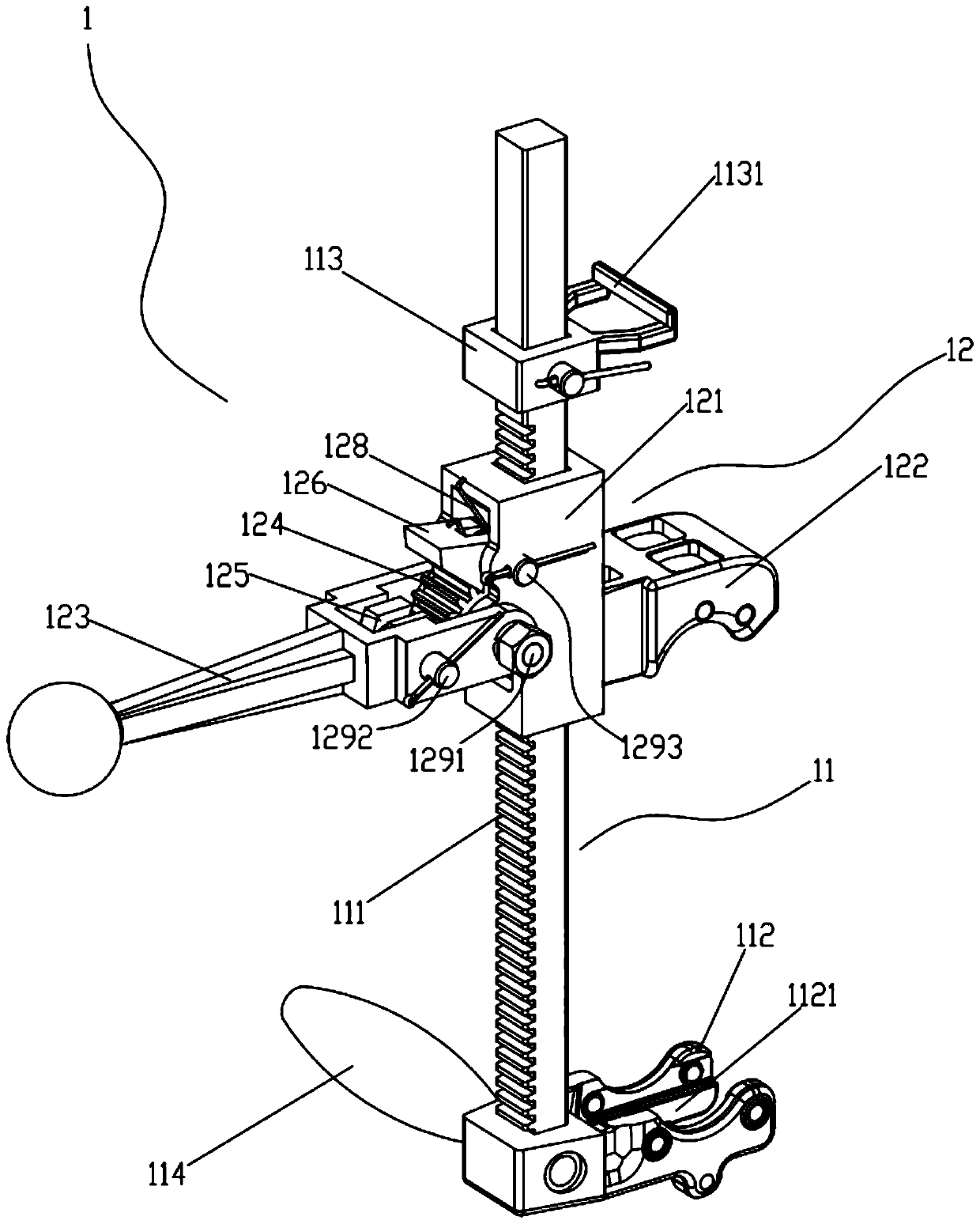

[0026] Such as Figure 1-4 As shown in the figure, a hand-operated cable terminal binding device includes a binding tool 1 and a wire clip 2.

[0027] The binding tool 1 includes a fixed frame 11 and a movable frame 12. The fixed frame 11 includes a rack 111, a support seat 112 fixedly arranged on the right side of the bottom end of the rack 111, and a limit frame 113 detachably connected to the top of the rack 111. , and the grip handle 114 fixedly arranged on one side of the support seat 112, the movable frame 12 includes a slider 121, a dynamic pressure seat 122 fixedly arranged on the right side of the slider 121, and a dynamic pressure seat 122 capable of driving the slider 121 along the rack 111 The driving mechanism that moves downward, the dynamic pressure seat 122 and the support seat 112 are arranged up and down, and the driving mechanism includes a rocker arm 123, a driving gear 124, a driving block 125, a locking block 126, a first torsion spring 127 and a second t...

Embodiment 2

[0033] On the basis of the technical solution of embodiment 1, the binding tool 1 has been improved as follows:

[0034] Such as Figure 5-6 As shown, two support seats 112 are fixedly arranged on the right side of the bottom end of the rack 111, and the two support seats 112 are solidly integrated and arranged side by side. Two corresponding dynamic pressure seats 122 are fixedly arranged on the right side of the slider 121. The pressing seats 122 are solidly integrated and arranged side by side. This arrangement enables one binding tool 1 to be loaded with two clamps 2 at the same time, thereby enabling a one-time operation to fix two clamps 2 on the upper cable, so that the fixed cable is more secure, and the cable can be fixed at a certain length. The inner parts are compressed and fitted together, which can effectively prevent the cable clip 2 from sliding due to the elastic force of the cable itself.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com