Asparagus dietary fiber and preparation method thereof

A technology of dietary fiber and asparagus, applied in the direction of food science, etc., can solve the problems of complex preparation methods, pollution, waste of ultrasonic energy consumption, etc., and achieve the effects of simple extraction process, increased economic benefits, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

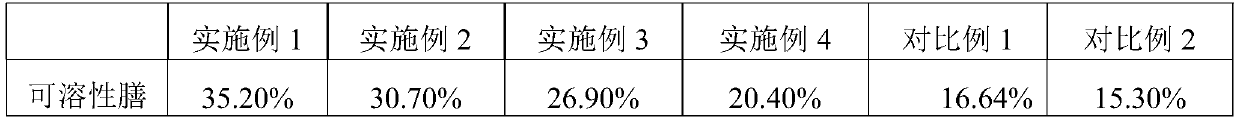

Examples

preparation example Construction

[0028] The present invention proposes a kind of preparation method of asparagus dietary fiber, comprising the following steps:

[0029] (1) Wash asparagus, dry in an oven at 70°C until the moisture content is below 5%, and crush to 40-80 mesh sieves to obtain asparagus powder.

[0030] (2) Mix the asparagus powder and water according to a mass ratio of 1:50 to 100, and grind and homogenize through a colloid mill to obtain a asparagus suspension; wherein, the grinding gap is 0.1 mm to 1.5mm, the grinding time is 5min~10min, and the grinding speed is 5000~15000r / min.

[0031] (3) Adjust the pH of the asparagus suspension to 3.0-7.0; wherein, the reagent used to adjust the pH is one or more of hydrochloric acid, acetic acid, sulfuric acid, and citric acid. Then, after adjusting the pH, 0.1% to 1.0% cellulase can also be added to the asparagus suspension, and enzymolysis is carried out at 40°C to 100°C for 1h to 5h, so as to further increase the yield of asparagus .

[0032] (4...

Embodiment 1

[0040] A kind of asparagus dietary fiber, its preparation method is as follows:

[0041] (1) Wash asparagus, dry at a temperature of 70° C. until the water content is below 5%, and crush to a 40-mesh sieve to make asparagus powder.

[0042] (2) Take asparagus powder 50g and put it in a container, add 4500g of water to soak.

[0043] (3) Pour the asparagus material liquid soaked in step (2) into a colloid mill for grinding, the grinding gap is 0.1mm-1.5mm, the grinding time is 5min-10min, the grinding speed is 5000-15000r / min, and the dragon mustard suspension.

[0044] (4) Adjust the pH of the asparagus suspension obtained in step (3) to 4.3 with citric acid, then add 0.5% cellulase, and perform enzymatic hydrolysis at 50° C. for 2.5 hours.

[0045] (5) Pour the asparagus suspension obtained in step (4) into a heating stirrer and heat to 100° C., and extract for 1 hour.

[0046] (6) Centrifuge the extract obtained in step (5) for 5 min at a rotational speed of 8000 r / min to...

Embodiment 2

[0053] A kind of asparagus dietary fiber, its preparation method is as follows:

[0054] (1) Wash asparagus, dry at a temperature of 70° C. until the water content is below 5%, and crush to a 50-mesh sieve to make asparagus powder.

[0055] (2) Take asparagus powder 50g and put it in a container, add 4500g of water to soak.

[0056] (3) Pour the asparagus material liquid soaked in step (2) into a colloid mill for grinding, the grinding gap is 0.1mm-1.5mm, the grinding time is 5min-10min, the grinding speed is 5000-15000r / min, and the dragon mustard suspension.

[0057] (4) Adjust the pH of the asparagus suspension obtained in step (3) to 5.0 with citric acid.

[0058] (5) Pour the asparagus suspension obtained in step (4) into a heating stirrer and heat to 90° C., and extract for 1 hour.

[0059] (6) Centrifuge the extract obtained in step (5) for 3 min at a rotational speed of 6000 r / min to obtain a supernatant and a precipitate.

[0060] (7) Freeze-dry and pulverize the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap