Enrichment device for separating micro-plastics from environmental soil and sediment

A technology for separation and enrichment of microplastics, applied in solid separation, centrifuge, preparation of test samples, etc., can solve the problems of cumbersome and time-consuming extraction of microplastics, low efficiency, low recovery rate, etc., and achieve low price and environmental protection The effect of less pollution and less coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

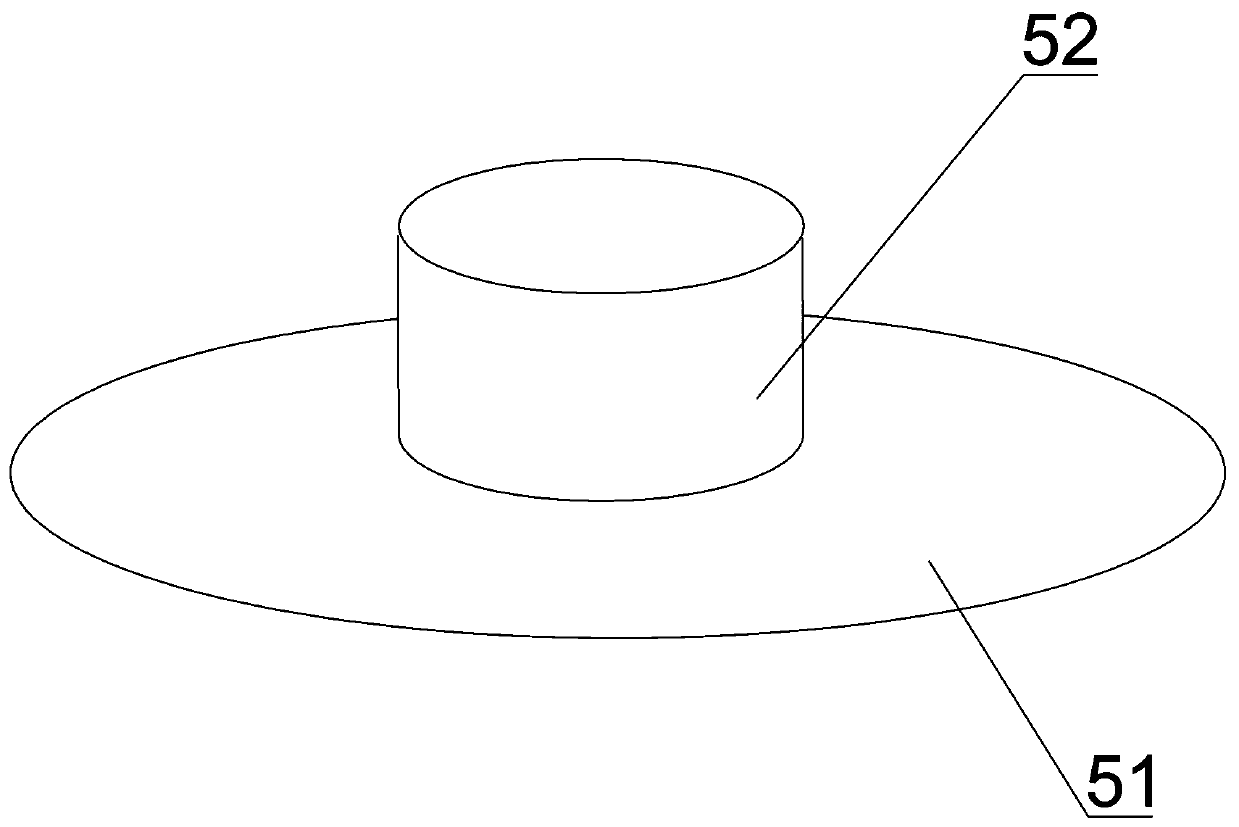

[0035] As an embodiment, the overflow device 5 is a combination of a circular bottom plate 51 and a hollow cylinder 52, the circular bottom plate 51 is provided with a through hole corresponding to the hollow cylinder 52, and the circular bottom plate 51 and the hollow cylinder 52 are combined. The included angle of the horizontal plane is 5-10°, which is 5° in this embodiment, and the liquid outlet is arranged on the lower side of the circular bottom plate 51, specifically at the lowest connection between the circular bottom plate 51 and the inside of the sample bottle 2. The liquid outlet of bottle 2 is connected with liquid outlet pipe 12.

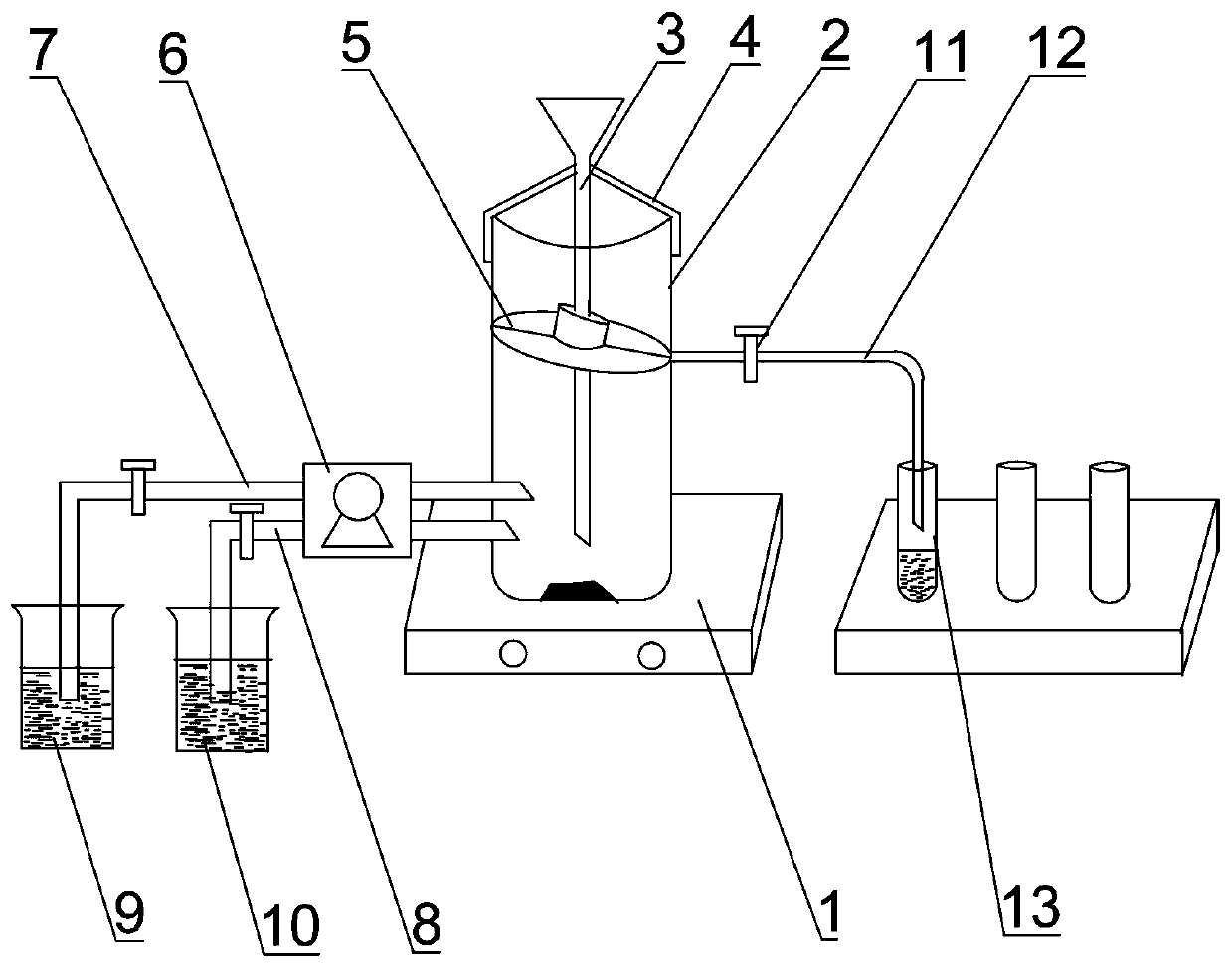

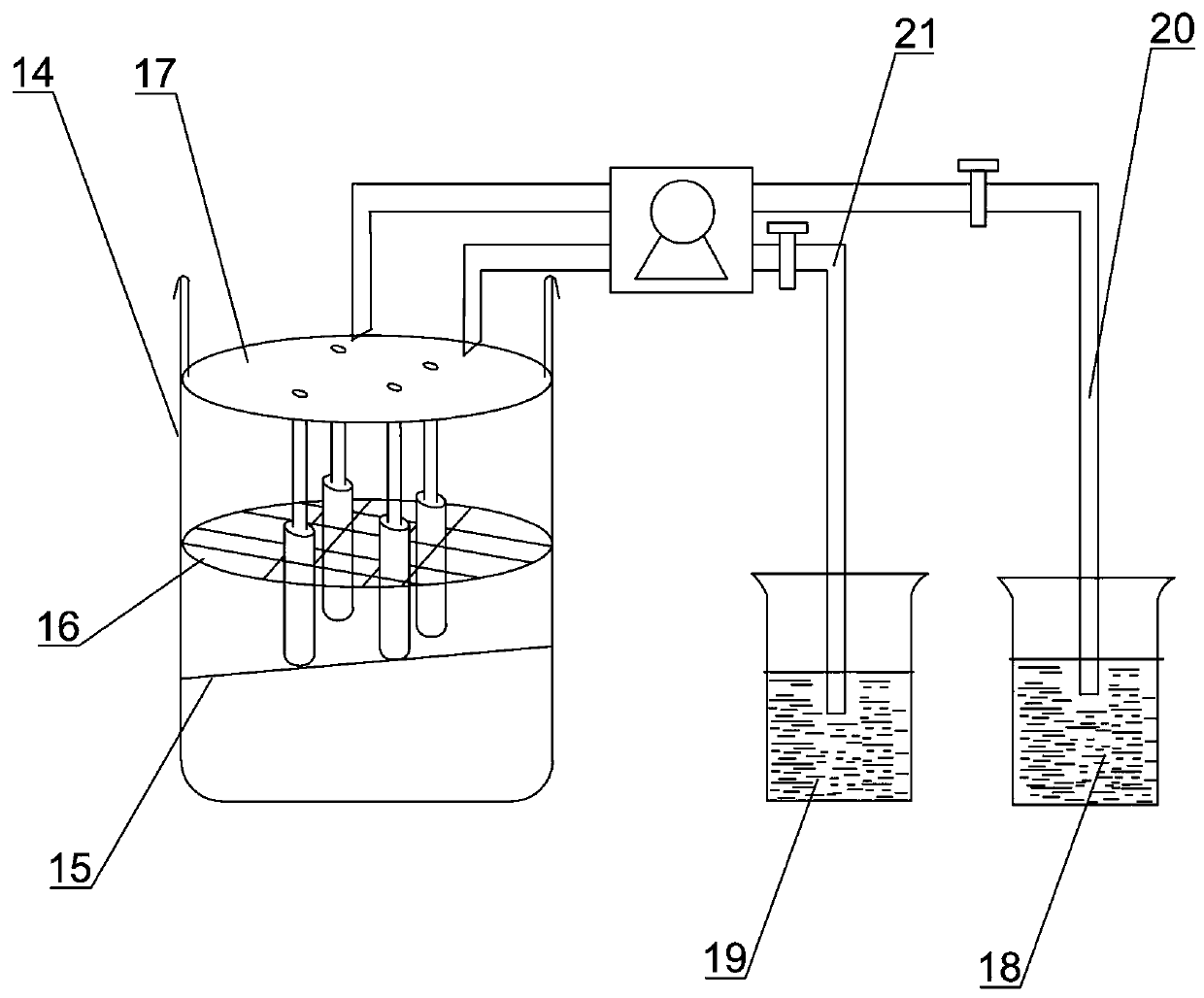

[0036] As an implementation, the No. 1 liquid inlet pipe 7 and the No. 2 liquid inlet pipe 8, the No. 3 liquid inlet pipe 20 and the No. 4 liquid inlet pipe 21 are all provided with a peristaltic pump 6. In this embodiment, the peristaltic pump is Multi-channel peristaltic pump. The outlet pipe 12, the No. 1 liquid inlet pipe 7, the No...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap