Liquid metal feeding mechanism for extruding and casting

A technology of liquid metal and feeding mechanism, applied in the field of die-casting, can solve the problems of safety accidents and high temperature, and achieve the effect of preventing safety accidents, simple structure and ensuring normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

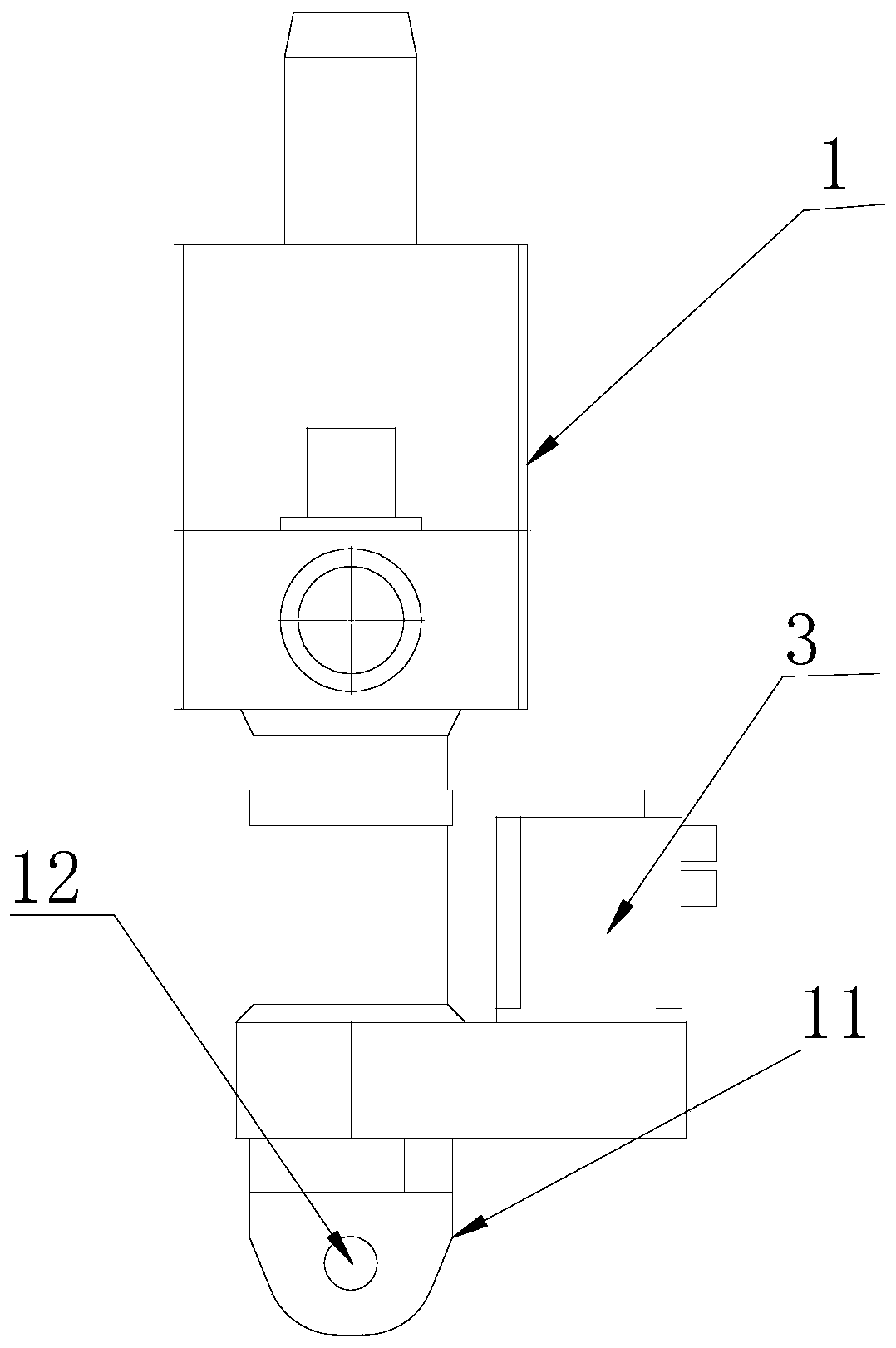

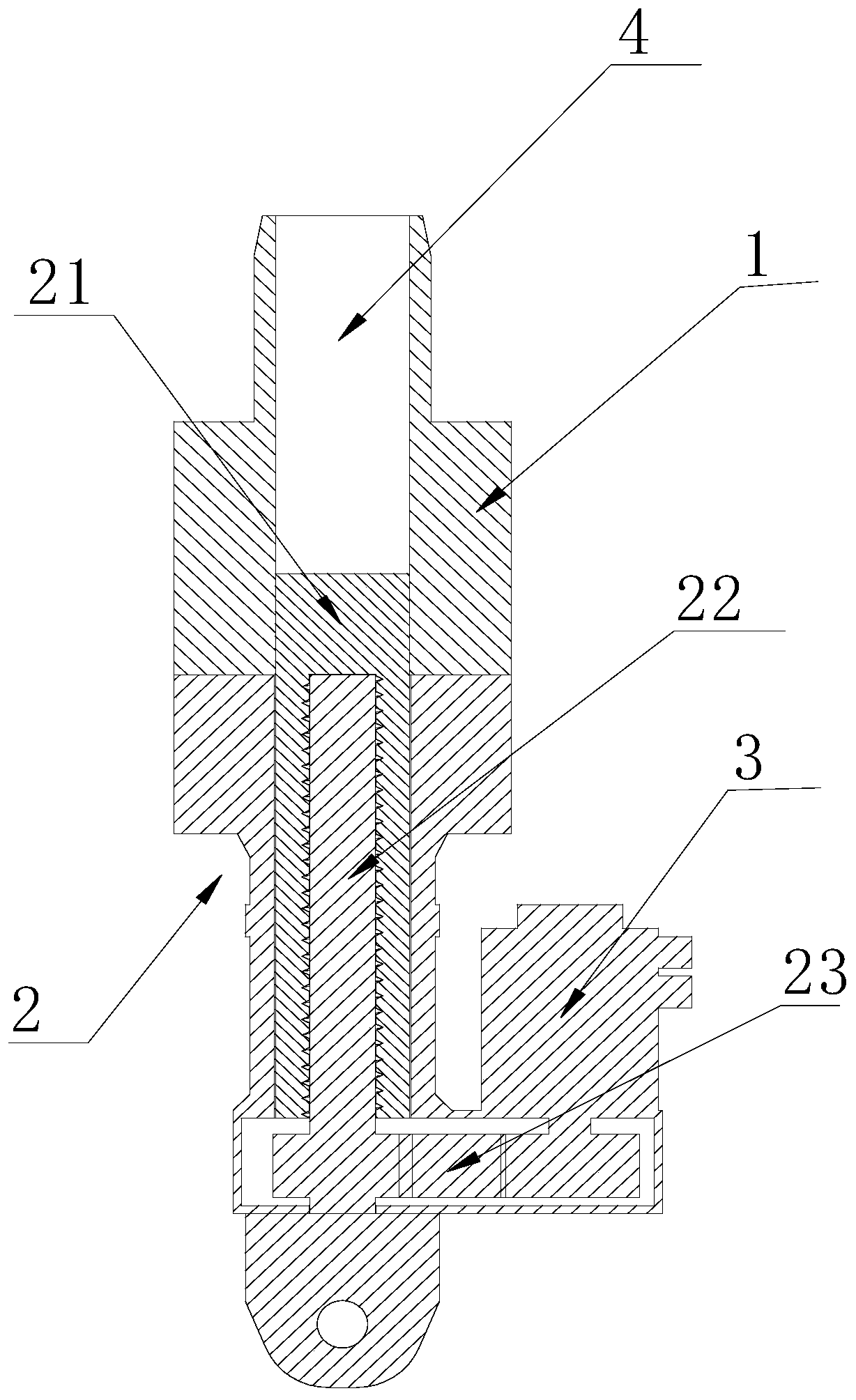

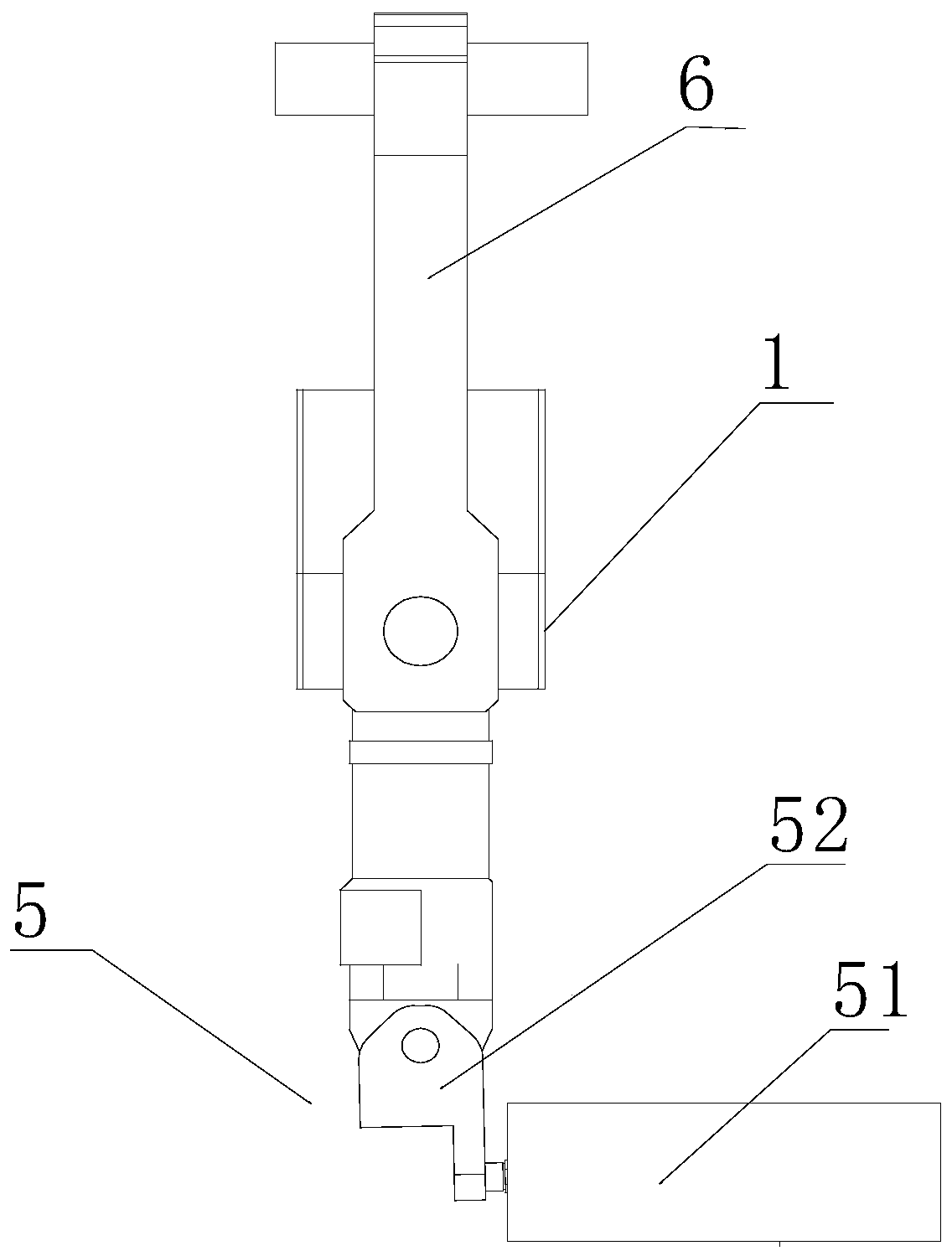

[0022] see Figure 1~2 , a liquid metal feeding mechanism for squeeze casting, the feeding mechanism is driven by electric motor.

[0023] The liquid metal described in this embodiment is aluminum liquid and copper liquid.

[0024] Further, the feeding mechanism is used to feed the liquid metal into the mold cavity of the peripheral mold.

[0025] Further refinement, the feeding mechanism includes a housing 1, the housing 1 is provided with a feeding chamber 4 with an open upper end, and also includes a feeding chamber 4 for sending the liquid metal in the feeding chamber 4 to the peripheral device. The feeding assembly 2 in the mold cavity of the mold, the feeding assembly 2 is driven by the servo motor 3 fixed on the housing, in practical application, not only limited to the servo motor, but also can choose different motors in this field, only However, its disadvantage is that the accuracy is low. In this embodiment, the servo motor 3 and the feeding assembly 2 may be con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com