Jacking extension device for spring assemblies of steam turbine generator

A steam turbine generator and spring assembly technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as many restricted conditions, inability to maintain spring assemblies, and failure to consider spring assembly maintenance, so as to prevent failures from expanding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A turbogenerator spring assembly jacking device provided by the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

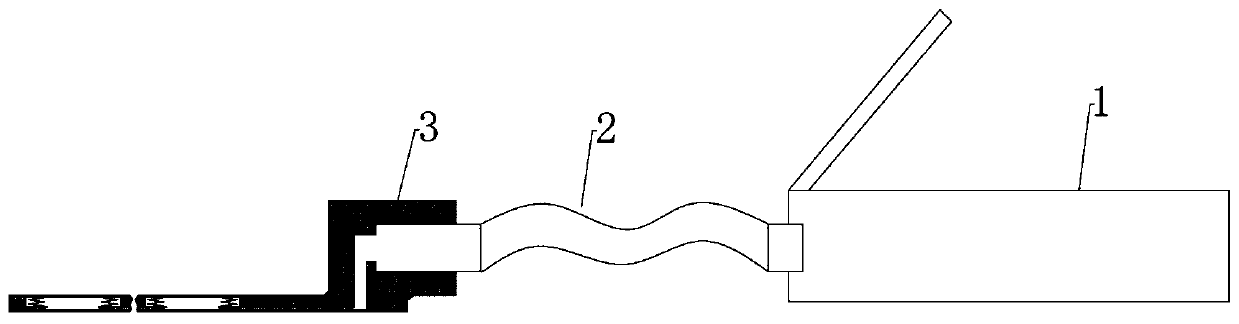

[0025] Such as figure 1 As shown, a turbogenerator spring assembly jacking device provided by the present invention includes an oil pressure supply device 1, a high-pressure hose 2, and a jacking mechanism 3. Connection; the other side of the high-pressure hose 2 is connected with the extension mechanism 3.

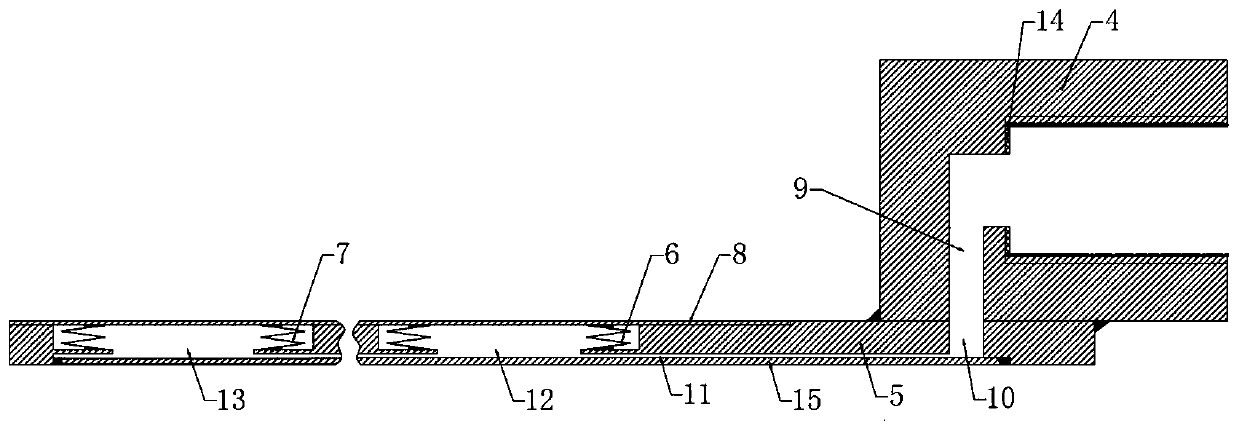

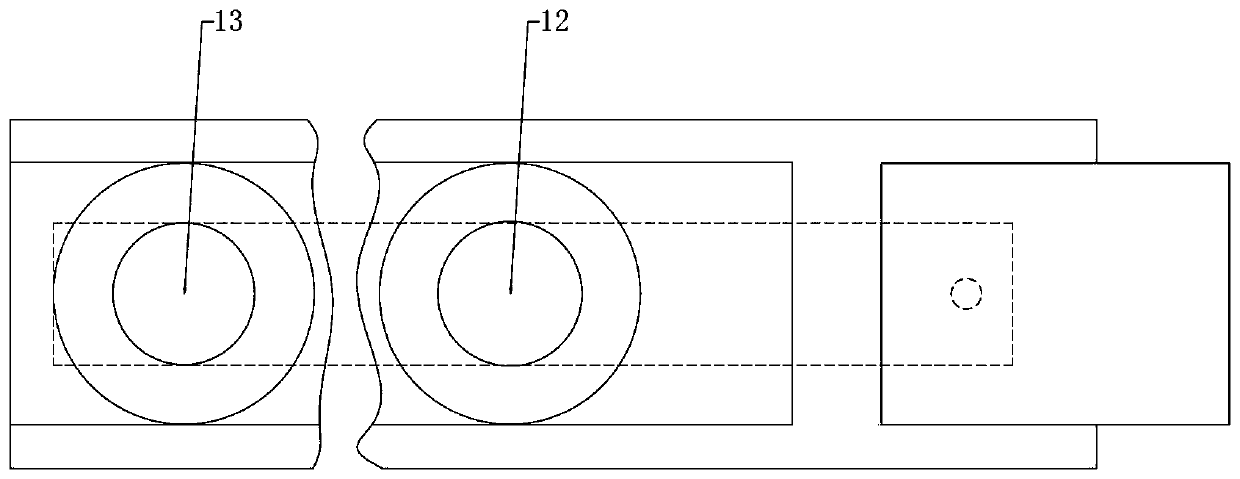

[0026] Such as figure 2 and image 3 As shown, the jacking mechanism 3 includes an oil inlet nut 4, an oil storage plate 5, a bellows I6, a bellows II7, a top extension flat steel 8, and an oil baffle plate 15. The oil inlet nut 4 has an oil hole I9, and the oil storage plate 5 is provided with oil hole II10, oil hole I9 and oil hole II10 are matched to connect the oil inlet nut 4 to the oil storage plate 5 by welding; the bottom of the oil storage plate 5 is milled wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com