Ultrastrong laser shock based thin plate connecting device and connecting method thereof

A technology of laser shock and connection device, applied in the directions of transportation and packaging, vehicle parts, etc., can solve the problems of coating or plating damage, inability to open threaded holes, affecting the appearance of plate connection, etc., to reduce the processing difficulty and shorten the processing cycle. , can control the effect of precision connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

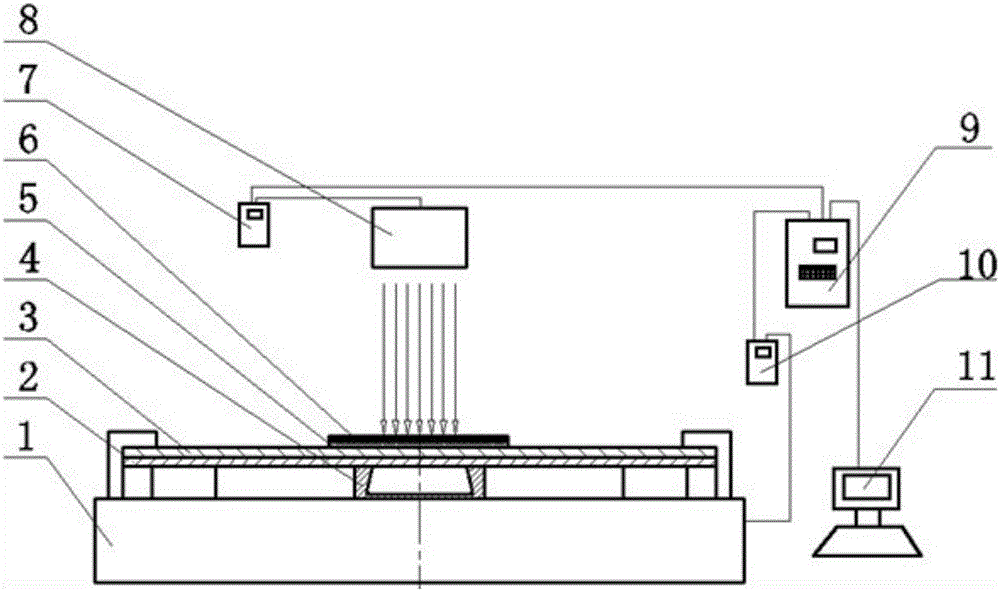

[0024] Such as figure 1 As shown, a thin plate connection device based on ultra-strong laser shock, which includes:

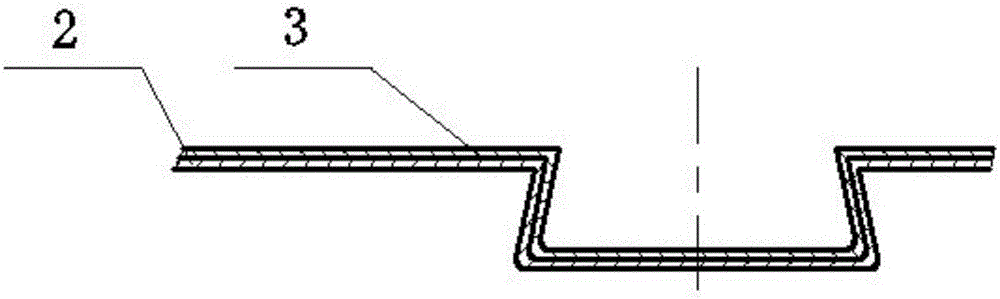

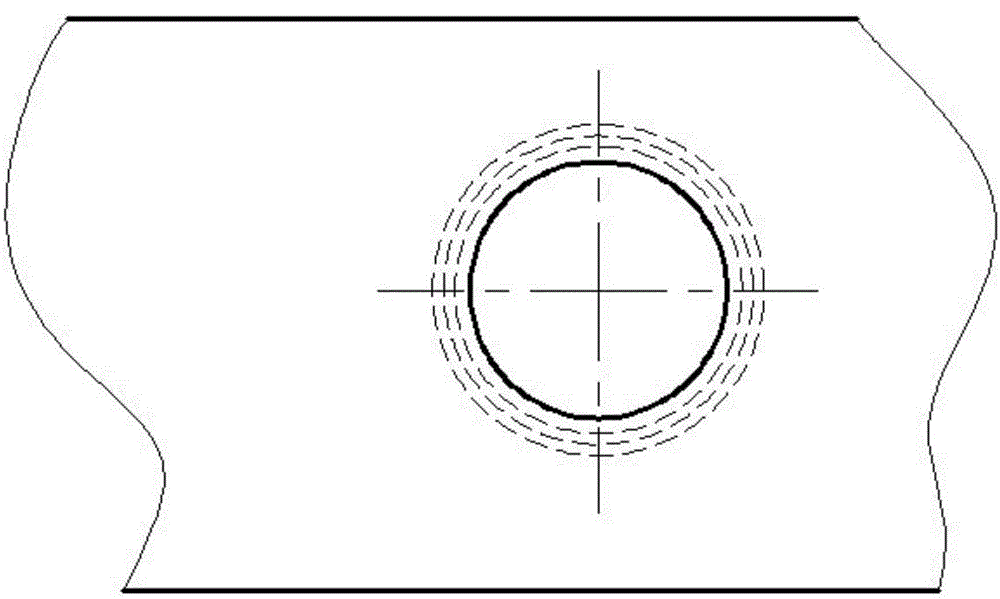

[0025] A workbench 1 is provided with a clamping support device 2 for stacking two thin plates 3 to be connected together, and the two thin plates 3 to be connected are stacked together to form a connection part;

[0026] A die 4, the die 4 is installed on the workbench 1, and the die 4 is supported below the connection part, so that the die 4 is used to support the connection part;

[0027] The laser irradiates the absorbing layer 5, and the laser irradiating absorbing layer 5 is coated on the upper surface of the connection part;

[0028] A plasma wave confinement layer 6, the plasma wave confinement layer 6 is arranged on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com