Swinging and translation plane mechanism and working method thereof

A technology of planar mechanism and working method, applied in the field of robotics, can solve problems such as low rigidity, low end precision, and poor dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

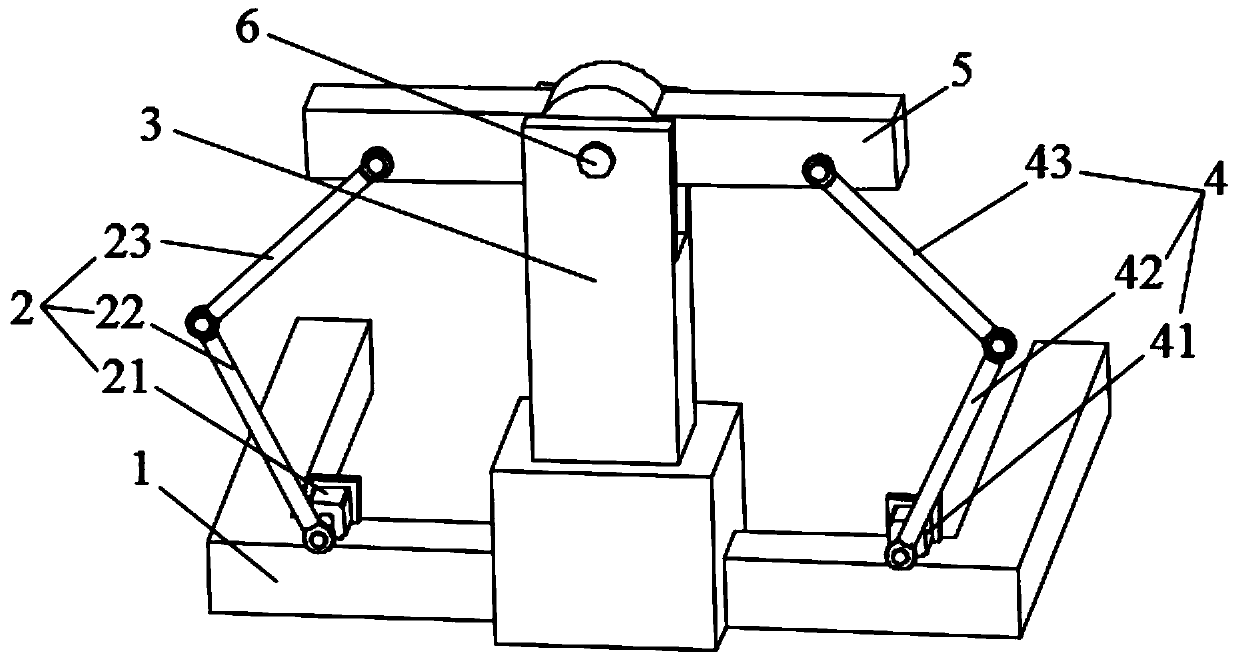

[0027] Such as figure 1 As shown, a planar mechanism of one swing and one translation includes a base 1, a first swing device 2, a telescopic device 3, a second swing device 4 and a moving platform 5, and the moving platform 5 passes through the first swing device 2 and the telescopic device respectively. 3. The second swinging device 4 is connected to the base 1, the first swinging device 2, the telescopic device 3, and the second swinging device 4 are all hinged with the moving platform 5, and the first swinging device 2 and the second swinging device 4 are respectively arranged on the telescopic device 3 sides. In practical application, the mechanism is fixed by the base 1, and the base 1 provides the supporting force; in operation, when doing translational movement, the first driver 21 and the second driver 41 reversely drive the swing degree of the first swing device 2 The same as the swing degree of the second swing device 4, the telescopic device 3 is driven to perform...

Embodiment 2

[0040] Such as figure 1 Shown, the working method of a kind of embodiment 1-swing-translation planar mechanism, comprises the steps:

[0041] When performing translational motion, the first driver 21 and the second driver 41 perform reverse drive, the swing degree of the first swing device 2 is the same as that of the second swing device 4, and the telescopic device 3 is driven to do telescopic movement, pushing the movable platform 5 do up and down translation;

[0042] When swinging, the swing degree of the first swing device 2 is different from the swing degree of the second swing device 4, and the expansion and contraction of the second swing device 4 remains unchanged, pushing the movable platform 5 to swing left and right;

[0043] Translation and swing can be performed simultaneously or separately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com