Unexploded ordnance destruction device and method

A technology of destroying devices and unexploded bombs, which is applied in the directions of manipulators, chucks, and manufacturing tools, etc., can solve the problems of high price of EOD robots, large direct economic losses, and reduced success rate of detonation. Operator requirements, the effect of improving the success rate and reducing the cost of bomb discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments. The descriptions here are used to provide a further understanding of the present invention and constitute a part of the application. The exemplary embodiments of the present invention and their descriptions are used to explain the present invention and do not constitute improper limitations to the present invention.

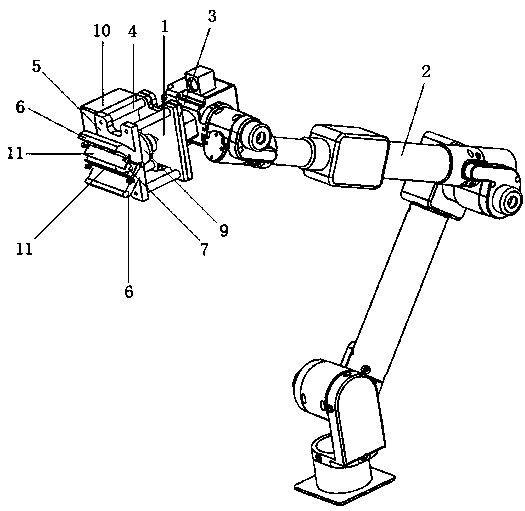

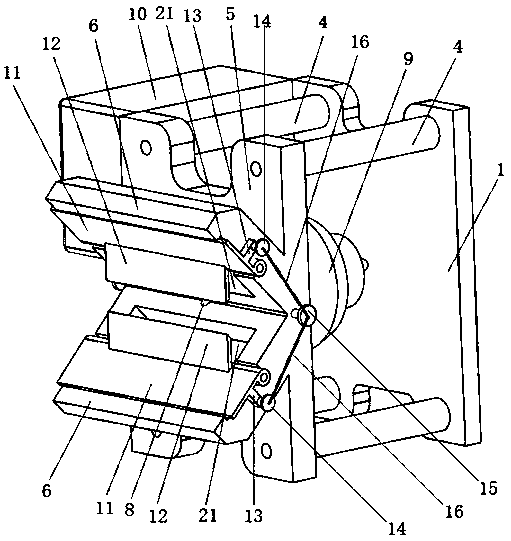

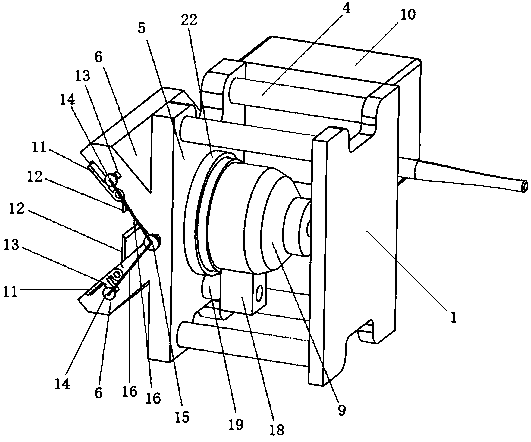

[0041] see Figure 1-8 As shown, a device for destroying unexploded bombs includes a bottom plate 1 that can be electromagnetically adsorbed, and the back side of the bottom plate 1 is used to connect with the mechanical arm electromagnet 3 at the front end of the robotic arm 2 by electromagnetic adsorption. The front of the bottom plate 1 is equipped with an electromagnetic gripper through several connecting rods 4, and the electromagnetic gripper is composed of a gripper connecting plate 5 and two gripper supporting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com