An automated warehouse storage cabinet

A technology for automated warehouses and storage cabinets, applied in storage devices, transportation and packaging, etc., can solve the problems that warehouse storage cabinets cannot be automatically lifted, and the placement of goods is not fully automated, so as to reduce manpower and material resources and reduce work intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

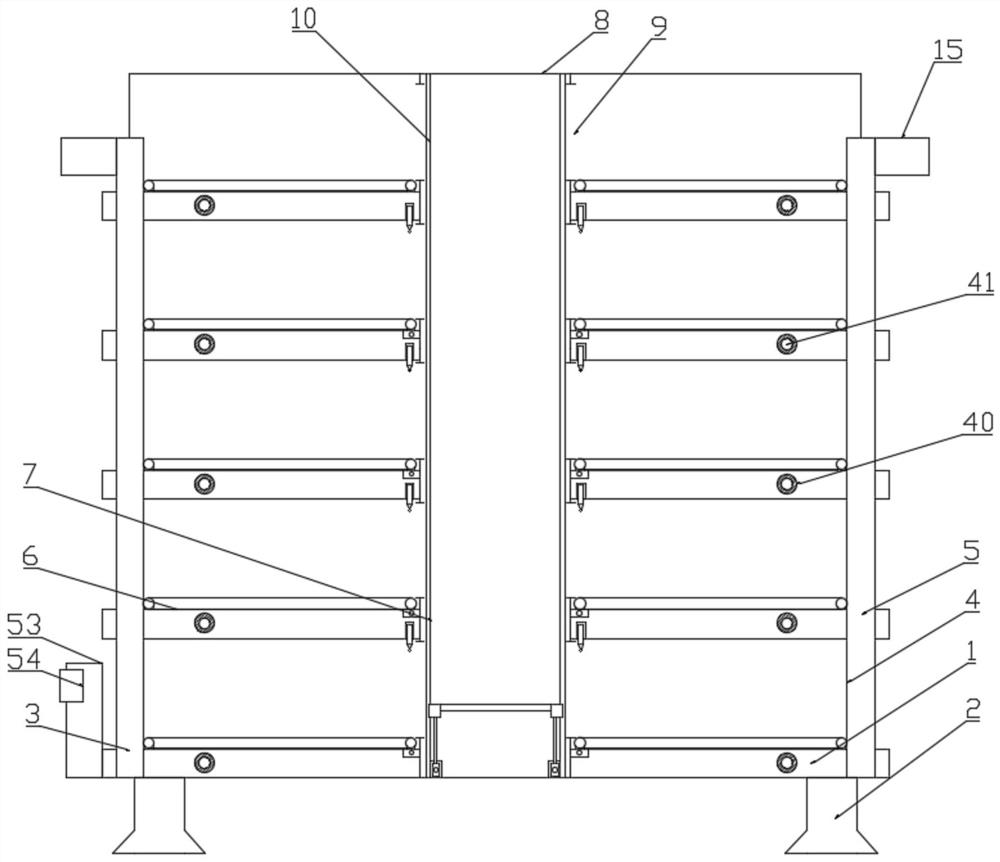

[0023] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6 shown.

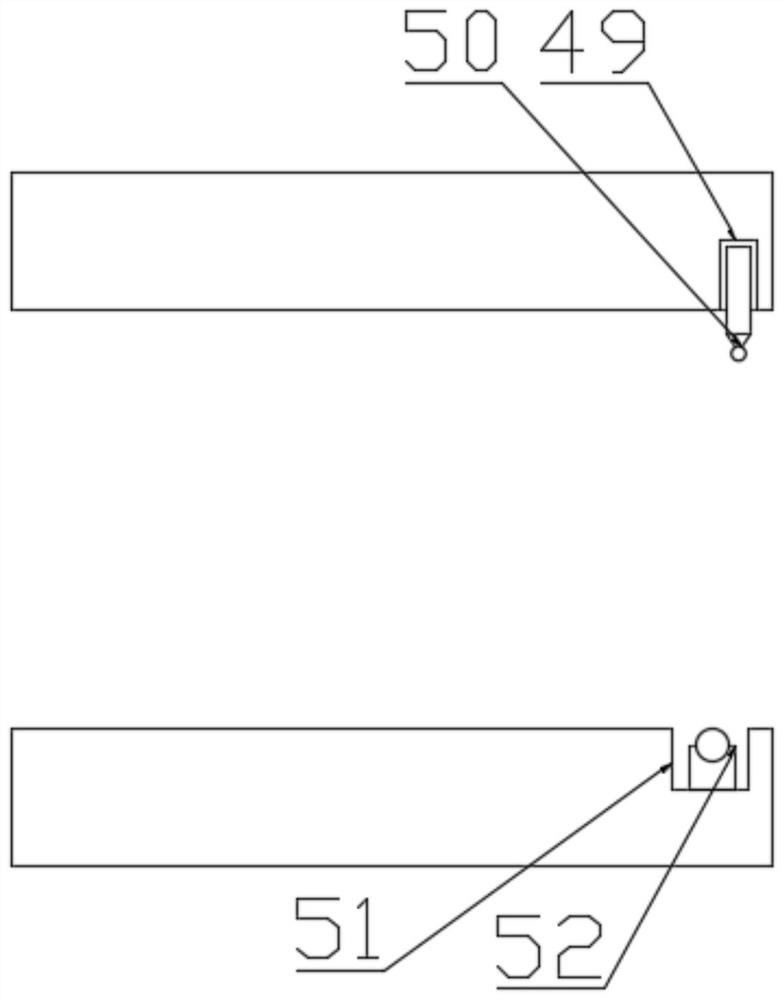

[0024] In this embodiment, the model of the controller 54 is MELSECiQ-R, and the signal sending end of the controller 54 is respectively connected with the first electric telescopic rod 44, the energized electromagnet 46, the laser lamp 50, the first linear motor 12, the first The signal receiving ends of the rotating motor 18, the first electric rotating rod 24, the blower 26, the vacuum cleaner 30, the second rotating motor 38, and the light-emitting diode 41 are connected for control, and the signal receiving end of the controller 54 is connected with the signal sending end of the infrared sensor 52 to connect.

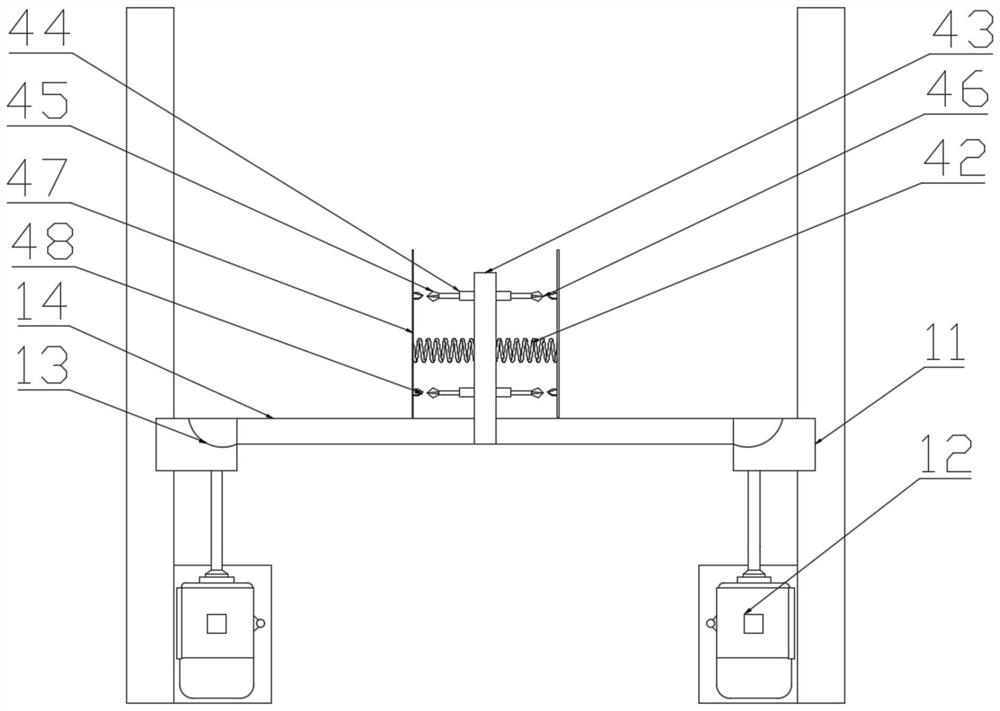

[0025] The invention point of the application lies in the structural design of the ejection mechanism, combined with the attached figure 2 And attached image 3 , the ejection mechanism includes a strong spring 42, and a baffle plate 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com