A handling industrial robot

An industrial robot and a technology for placing boards, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of limited physical strength of workers, limit work efficiency, consume large labor force, etc., save manpower and time, improve efficiency, and rotate the process stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

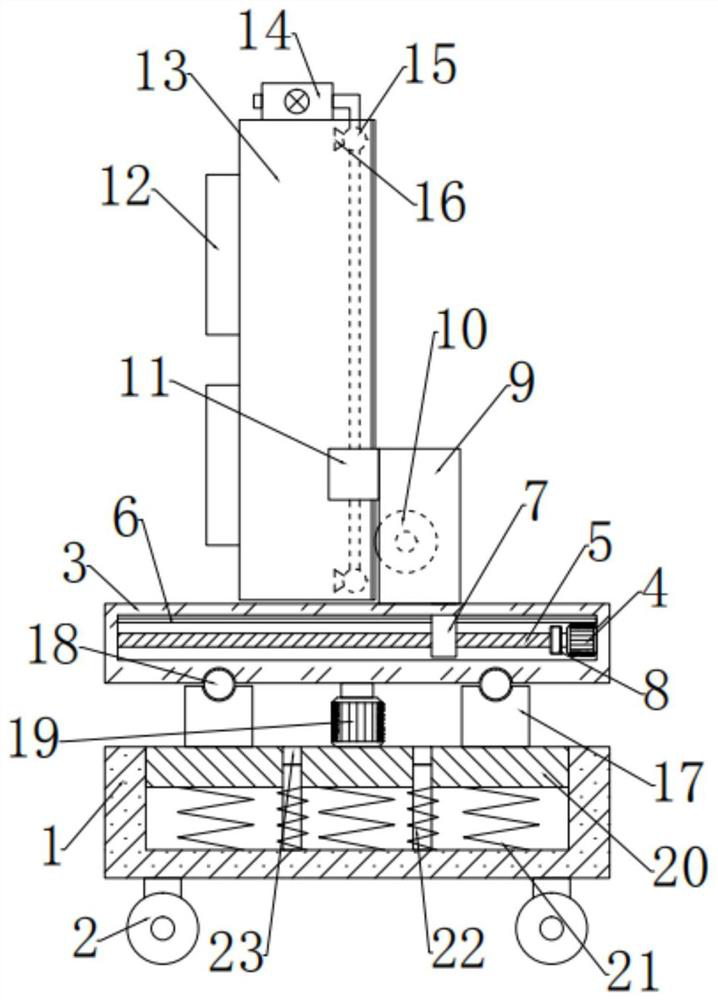

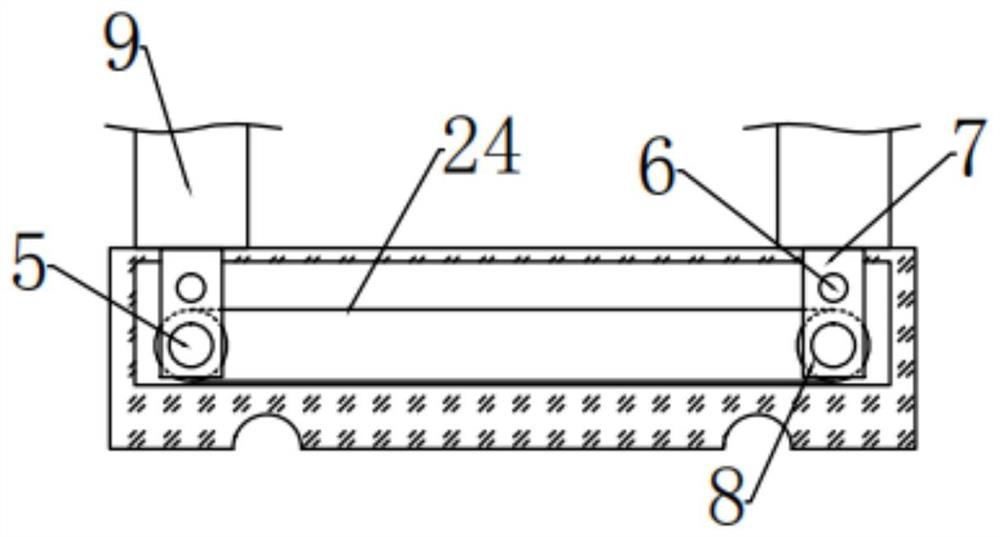

[0028] see Figure 1-4 , in an embodiment of the present invention, a transporting industrial robot includes a base 1, the bottom of the base 1 is fixedly connected with electric casters 2, the upper side of the base 1 is provided with a placement plate 3, and the placement plate 3 and the base 1 A shock-absorbing mechanism is arranged between them, and a gripping mechanism is arranged at the top of the placement board 3 , and the gripping mechanism is connected with a driving mechanism arranged inside the placement board 3 .

Embodiment 2

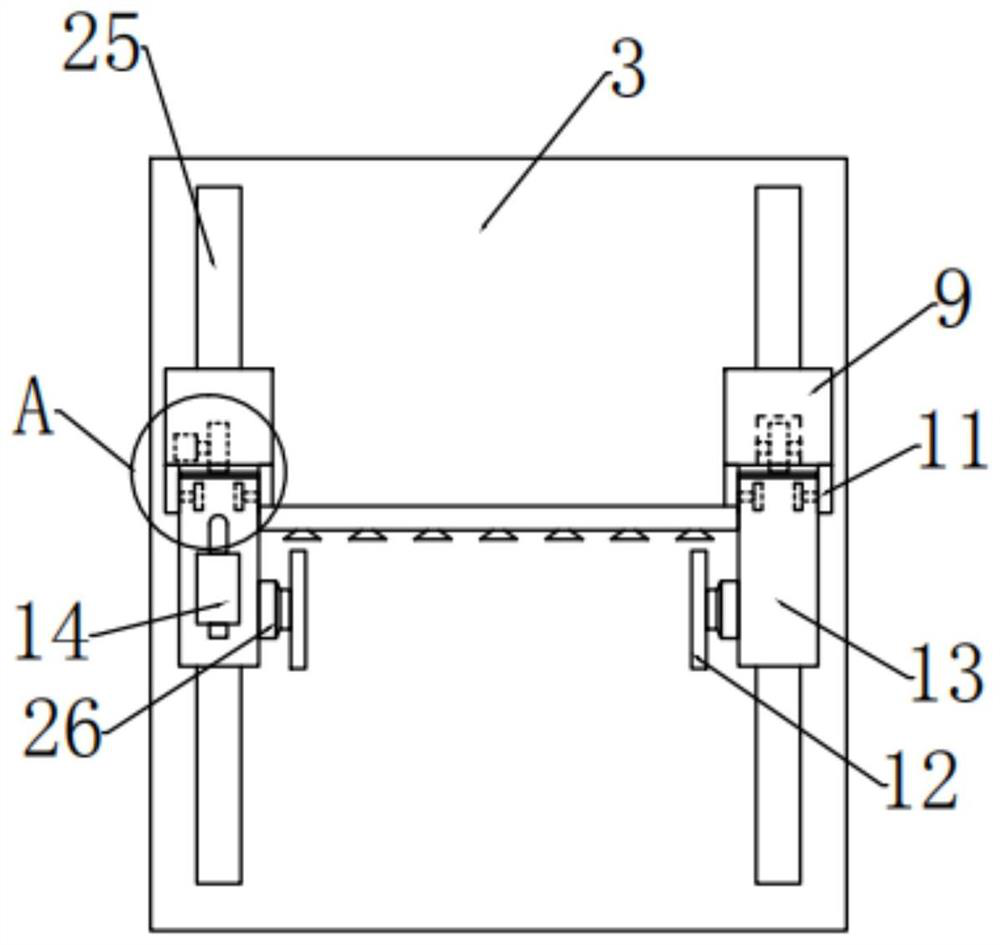

[0030] In this embodiment, the clamping mechanism includes a connecting block 9, the connecting block 9 is arranged on the front and rear sides of the top of the placing plate 3, the left side of the connecting block 9 is provided with a movable block 13, and the inner side of the connecting block 9 is bolted. A third motor is connected, and the output end of the third motor is connected to the gear 10. The movable block 13 is fixedly connected to a rack connected to the gear 10 near the connecting block 9. The movable block 13 has two front and rear sides. Both sides are provided with a baffle plate 11 fixedly connected with the connecting block 9, and the side of the baffle plate 11 close to the movable block 13 is fixedly connected with a limit block 27 which is slidably connected with the movable block 13, and the movable block 13 on both sides is opposite. One side is all provided with clamping plate 12, fixed connection is provided with telescopic rod 26 between described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com