Cleaning device for cleaning rotor plate of spinning rotor with cleaning head

A cleaning device, cleaning head technology, applied in the direction of spinning machine, open-end spinning machine, cleaning method and utensils, etc., can solve the problem of angle deviation, cleaning head spinning rotor misalignment, insufficient maintenance Spinning rotor and other problems to achieve the effect of avoiding slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

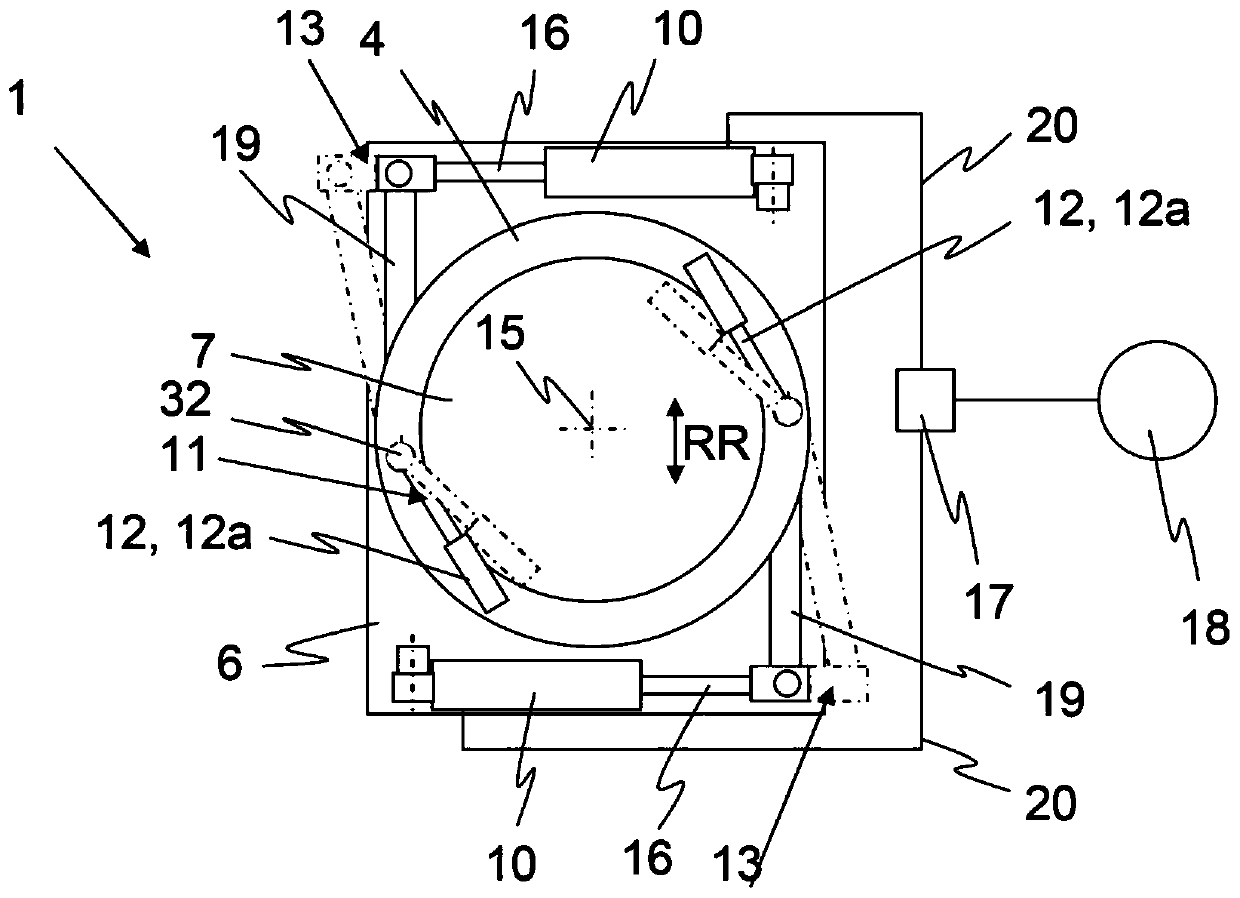

[0040] In the following description of the figures, the same reference numerals are used for identical and / or at least equivalent features in the various exemplary embodiments with respect to their design and / or mode of action. If certain features are not reproduced in detail in a certain figure, their design and / or mode of operation correspond to those of the features described above with reference to other figures. Also, generally only a corresponding one of a plurality of like features or components is illustrated and labeled in the figures for the sake of clarity.

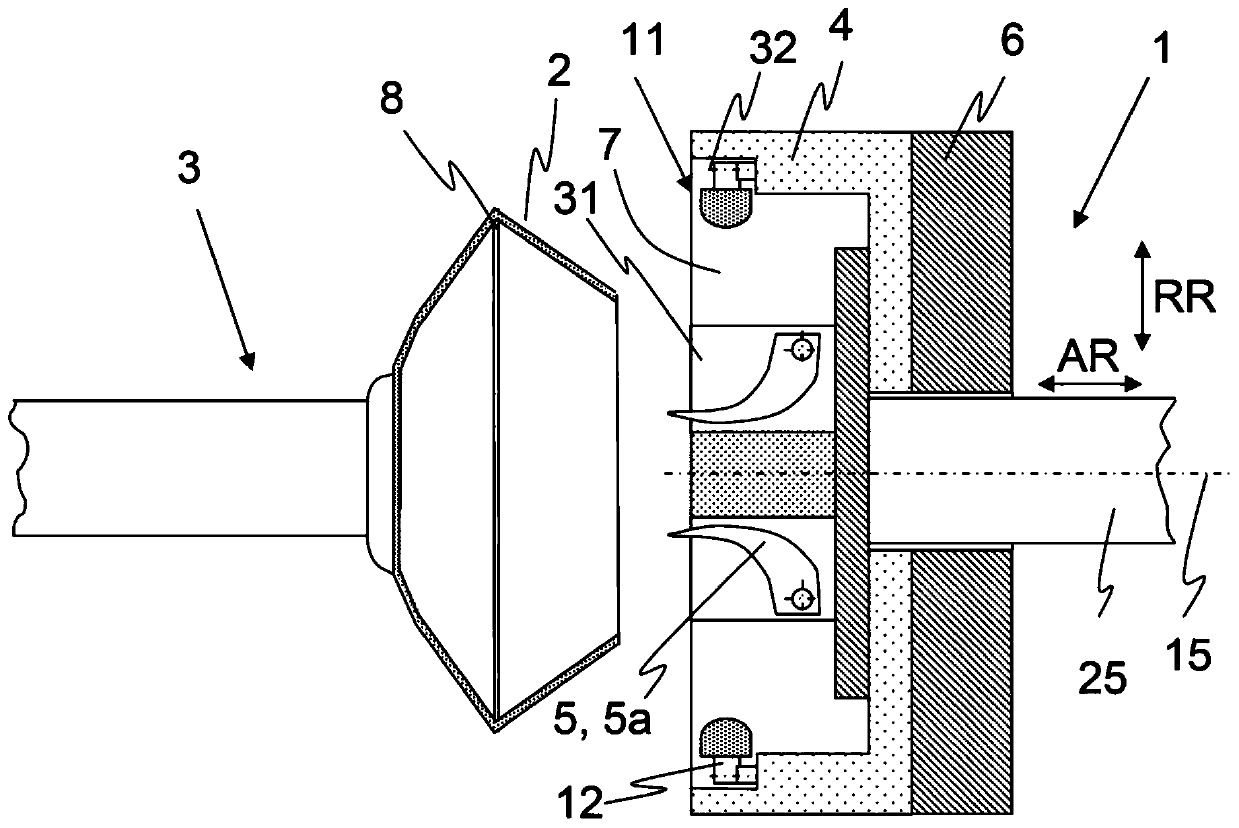

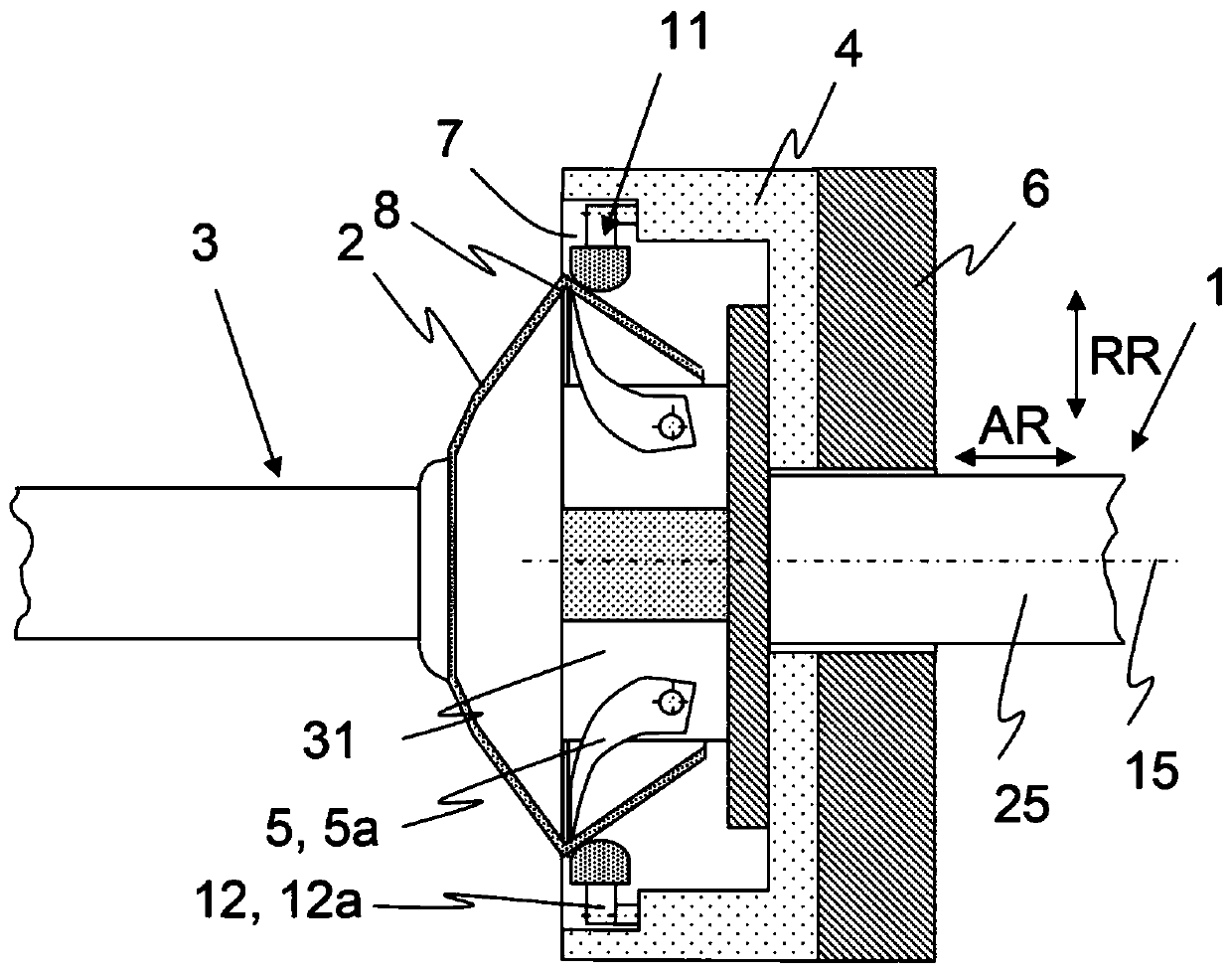

[0041] figure 1 A schematic side sectional view of a cleaning device 1 for cleaning a rotor disk 2 of a spinning rotor 3 is shown. The spinning rotor 3 is built into the spinning box of the free-end spinning machine as usual (the spinning box and the spinning machine are not shown in this figure, only in the Figure 8 A spinning machine 24 is shown schematically in ) and is used to spin the fiber material int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com